Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Fillers Included

- Polymer Name

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Composites Processing Methods

- Plastics & Elastomers Processing Methods

Properties

- Physical Form

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Rheological Calculation Properties

- Other Properties

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 11000 / 7000 | MPa | ISO 527-1/-2 |

| Tensile Modulus (At -40°C) | 12000 / - | MPa | ISO 527-1/-2 |

| Tensile Modulus (At 100°C) | 5100 / - | MPa | ISO 527-1/-2 |

| Tensile Modulus (At 120°C) | 4850 / - | MPa | ISO 527-1/-2 |

| Tensile Modulus (At 150°C) | 4300 / * | MPa | ISO 527-1/-2 |

| Tensile Modulus (At 160°C) | 4050 / * | MPa | ISO 527-1/-2 |

| Tensile Modulus (At 200°C) | 2800 / * | MPa | ISO 527-1/-2 |

| Stress at Break | 195/125 | MPa | ISO 527-1/-2 |

| Stress at Break (At -40°C) | 250 / - | MPa | ISO 527-1/-2 |

| Stress at Break (At 100°C) | 100 / - | MPa | ISO 527-1/-2 |

| Stress at Break (At 120°C) | 95 / - | MPa | ISO 527-1/-2 |

| Stress at Break (At 150°C) | 82 / * | MPa | ISO 527-1/-2 |

| Stress at Break (At 160°C) | 75 / * | MPa | ISO 527-1/-2 |

| Stress at Break (At 180°C) | 65 / * | MPa | ISO 527-1/-2 |

| Stress at Break (At 200°C) | 50 / * | MPa | ISO 527-1/-2 |

| Strain at Break | 3.5 / 7 | % | ISO 527-1/-2 |

| Strain at Break (At -40°C) | 3.1 / - | % | ISO 527-1/-2 |

| Strain at Break (At 120°C) | 10.4 / - | % | ISO 527-1/-2 |

| Strain at Break (At 150°C) | 10.8 / * | % | ISO 527-1/-2 |

| Strain at Break (At 160°C) | 11 / * | % | ISO 527-1/-2 |

| Strain at Break (At 180°C) | 11.3 / * | % | ISO 527-1/-2 |

| Strain at Break (At 200°C) | 11.6 / * | % | ISO 527-1/-2 |

| Flexural Modulus | 10700 / 6450 | MPa | ISO 178 |

| Flexural Modulus (At 120°C) | 4900 / * | MPa | ISO 178 |

| Flexural Modulus (At 160°C) | 4200 / * | MPa | ISO 178 |

| Flexural Strength | 305 / 180 | MPa | ISO 178 |

| Flexural Strength (At 120°C) | 120 /* | MPa | ISO 178 |

| Flexural Strength (At 160°C) | 95 / * | MPa | ISO 178 |

| Charpy Impact Strength (At +23°C) | 90 / 100 | kJ/m² | ISO 179/1eU |

| Charpy Impact Strength (At -30°C) | 75 / 75 | kJ/m² | ISO 179/1eU |

| Charpy Notched Impact Strength (At +23°C) | 14 / 24 | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (At -30°C) | 12 / 12 | kJ/m² | ISO 179/1eA |

| Izod Notched Impact Strength (At +23°C) | 15 / - | kJ/m² | ISO 180/1A |

| Weldline Strength (At 4/* mm Thickness) | 100 / 60 | MPa | ISO 527-1/-2 |

| Weldline Strain (At 4/* mm Thickness) | 1.2 / 1.3 | % | ISO 527-1/-2 |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (At 10°C/min) | 220 / * | °C | ISO 11357-1/-3 |

| Temperature of Deflection Under Load (At 1.80 MPa) | 210 / * | °C | ISO 75-1/-2 |

| Temperature of Deflection Under Load (At 0.45 MPa) | 220 / * | °C | ISO 75-1/-2 |

| Coefficient of Linear Thermal Expansion (Parallel) | 0.2 / * | E-4/°C | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (Normal) | 0.6 / * | E-4/°C | ISO 11359-1/-2 |

| Burning Behavior (At 1.5/* mm Nominal Thickness) | UL HB | class | IEC 60695-11-10 |

| Burning Behavior (At 3.0/* mm Nominal Thickness) | UL HB | class | IEC 60695-11-10 |

| Burning Behavior (At 0.75/* mm Nominal Thickness) | HB | class | IEC 60695-11-10 |

| Relative Temperature Index (Electrical, at 0.71/* mm Thickness) | 140 / * | °C | UL746B |

| Relative Temperature Index (Electrical, at 3/* mm Thickness) | 140 / * | °C | UL746B |

| Relative Temperature Index (With Impact, at 0.71/* mm Thickness) | 120 / * | °C | UL746B |

| Relative Temperature Index (With Impact, at 3/* mm Thickness) | 130 / * | °C | UL746B |

| Relative Temperature Index (Without Impact, at 0.71/* mm Thickness) | 140 / * | °C | UL746B |

| Relative Temperature Index (Without Impact, at 3/* mm Thickness) | 150 / * | °C | UL746B |

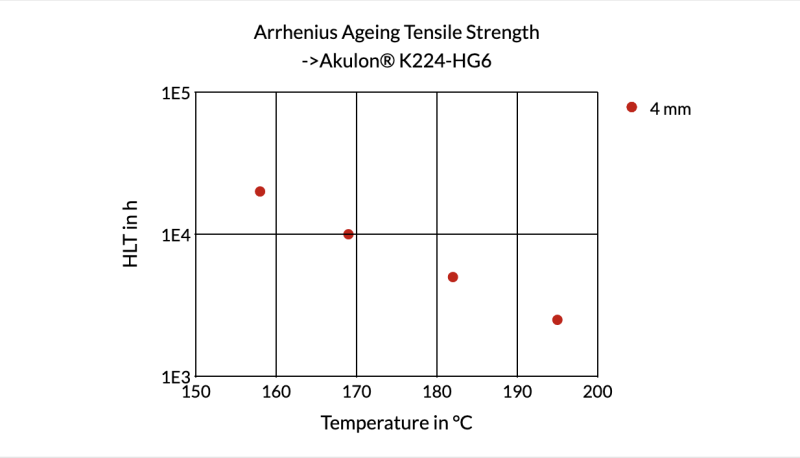

| Thermal Index (At 2500 hrs) | 195 / * | °C | IEC 60216/ISO 527-1/-2 |

| Thermal Index (At 5000 hrs) | 182 / * | °C | IEC 60216/ISO 527-1/-2 |

| Thermal Index (At 10000 hrs) | 169 / * | °C | IEC 60216/ISO 527-1/-2 |

| Thermal Index (At 20000 hrs) | 158 / * | °C | IEC 60216/ISO 527-1/-2 |

| Value | Units | Test Method / Conditions | |

| Relative Permittivity (At 100Hz) | 4.8 / - | — | IEC 62631-2-1 |

| Relative Permittivity (At 1 MHz) | 4.3 / - | — | IEC 62631-2-1 |

| Dissipation Factor (100 Hz) | 170 / - | E-4 | IEC 62631-2-1 |

| Dissipation Factor (1 MHz) | 220 / - | E-4 | IEC 62631-2-1 |

| Volume Resistivity | 1E12 / 1E10 | Ohm*m | IEC 62631-3-1 |

| Electric Strength | 35 / 25 | kV/mm | IEC 60243-1 |

| Value | Units | Test Method / Conditions | |

| Density of Melt | 1150 / * | kg/m³ | — |

| Thermal Conductivity of Melt | 0.27 / * | W/(m K) | — |

| Specific Heat Capacity Melt | 2110 / * | J/(kg K) | — |

| Effective Thermal Diffusivity | 1.4E-7 / * | m²/s | — |

| Value | Units | Test Method / Conditions | |

| Water Absorption | 5.9 / * | % | Sim. to ISO 62 |

| Humidity Absorption | 1.8 / * | % | Sim. to ISO 62 |

| Density | 1400 / - | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (At 275/* °C, 5/* kg) | 40 / * | cm³/10min | ISO 1133 |

| Melt Flow Index MFI (At 275/* °C, 5/* kg) | 48 / * | g/10min | ISO 1133 |

| Molding Shrinkage (Parallel) | 0.3 / * | % | ISO 294-4 |

| Molding Shrinkage (Normal) | 0.9 / * | % | ISO 294-4 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

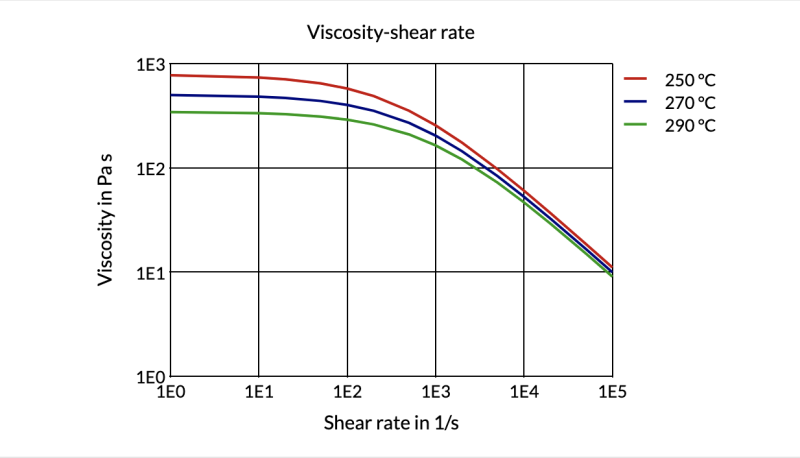

- Viscosity-Shear Rate

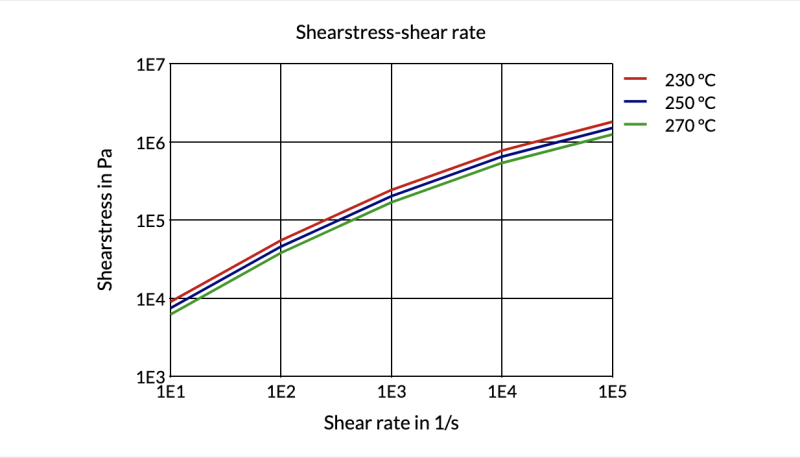

- Shear Stress-Shear Rate

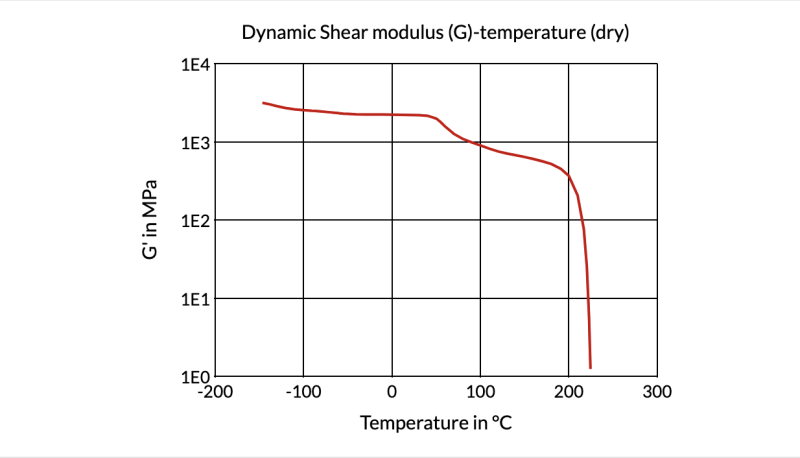

- Dynamic Shear Modulus (G)-Temperature (Dry)

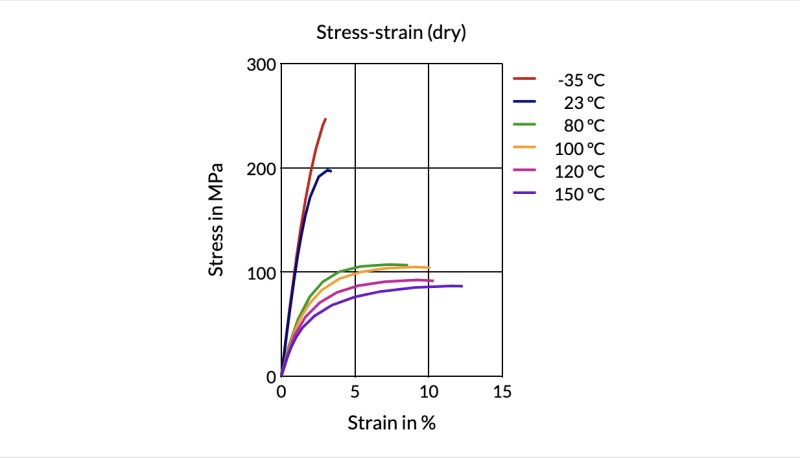

- Stress-Strain (Dry)

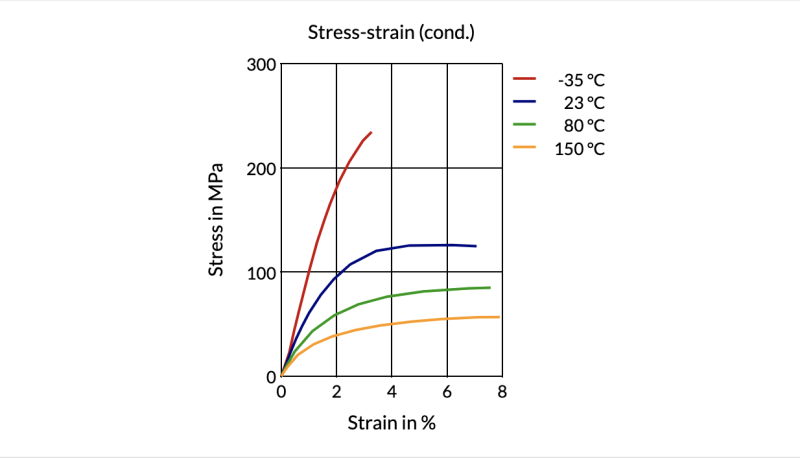

- Stress-Strain (Cond.)

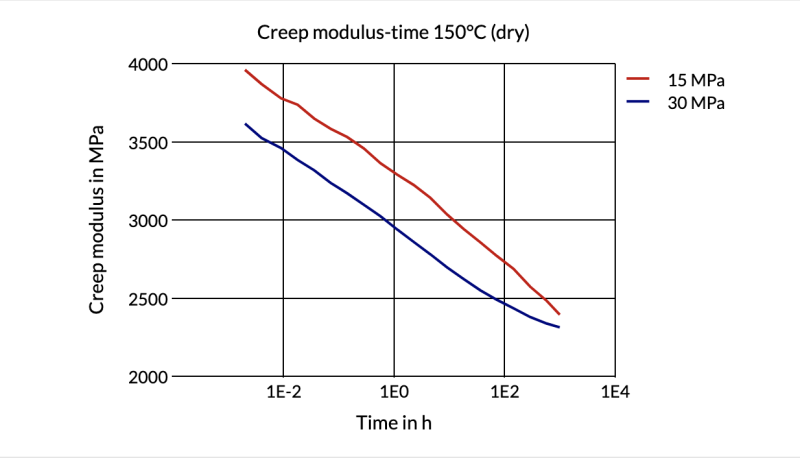

- Creep Modulus-Time 150°C (Dry)

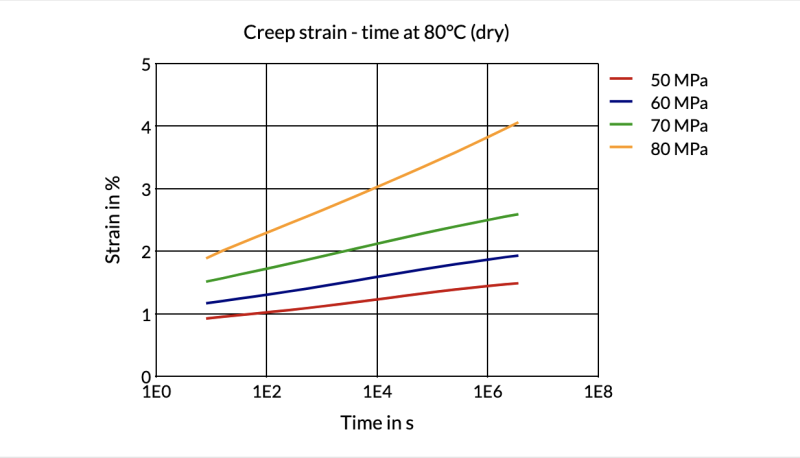

- Creep Strain-Time at 80°C (Dry)

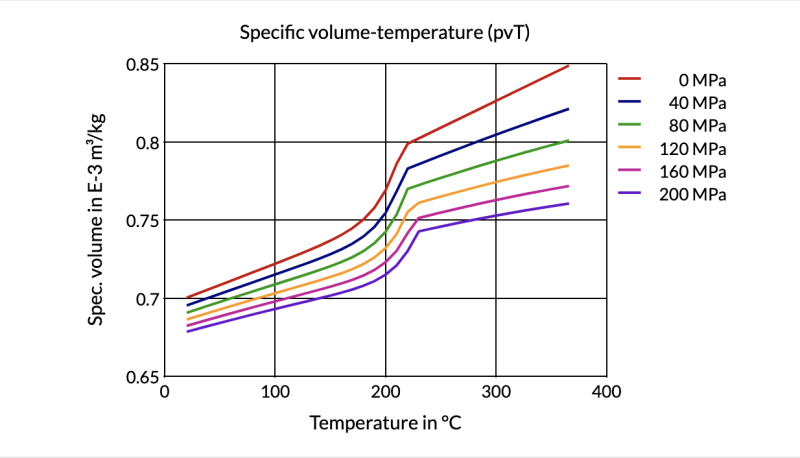

- Specific Volume-Temperature (pvT)

- Arrhenius Ageing Tensile Strength ->Akulon® K224-HG6

- Chemical Resistance Data

Chemical Name Chemical Resistance Acetone at 23°C Resistant Acetophenone at 23°C Resistant Acetylene at 23°C Resistant Aliphatic amines at 23°C Resistant Aliphatic hydrocarbons at 23°C Resistant Alkylbenzenes at 23°C Resistant Aluminum acetate (saturated) at 23°C Resistant Aluminum chloride (10% by mass) at 23°C Resistant Aluminum hydroxide (saturated) at 23°C Resistant Aluminum trichloride (10% by mass) at 23°C Resistant Amino acids (saturated) at 23°C Resistant Ammonia at 23°C Resistant Ammonium chloride (35% by mass) at 23°C Resistant Ammonium salts of mineral acids (10% by mass) at 23°C Resistant Ammonium thiocyanate (saturated) at 23°C Resistant Amyl acetate at 23°C Resistant Amyl alcohol at 23°C Resistant Aromatic hydrocarbons at 23°C Resistant Benzene at 23°C Resistant Benzene at 80°C Resistant Beverages at 23°C Resistant Bromochlorodifluoromethane at 23°C Resistant Bromotrifluoromethane at 23°C Resistant Butadiene at 23°C Resistant Butane at 23°C Resistant Butanediols at 23°C Resistant Butanols at 23°C Resistant Butene glycol at 23°C Resistant Butene-1 at 23°C Resistant Butter at 23°C Resistant Butyl acetate at 23°C Resistant Butyl acrylate at 23°C Resistant Butyl glycolate at 23°C Resistant Butyl phthalate at 23°C Resistant Butyrolactone at 23°C Resistant Calcium chloride (10% by mass) at 23°C Resistant Calcium chloride (saturated) at 23°C Resistant Calcium hydroxide (saturated) at 23°C Resistant Camphor (alcoholic) (50% by mass) at 23°C Resistant Caprolactam (50% by mass) at 23°C Resistant Carbon disulfide at 23°C Resistant Carbon tetrachloride at 23°C Resistant Casein at 23°C Resistant Chlorobenzene at 23°C Resistant Chlorobenzene at 50°C Resistant Chlorodifluoroethane at 23°C Resistant Chlorodifluoromethane at 23°C Resistant Chlorofluoroethylene at 23°C Resistant cis-2-butene at 23°C Resistant Citric acid (10% by mass) at 23°C Resistant Copper sulfate (10% by mass) at 23°C Resistant Cycloalcohols (incl their esters) at 23°C Resistant Cycloalkanes at 23°C Resistant Cycloalkanones at 23°C Resistant Decalin at 23°C Resistant Developer (photografic) at 23°C Resistant Dibutyl phthalate at 23°C Resistant Dibutyl phthalate at 60°C Resistant Dichlorobenzene at 23°C Resistant Dichloroethane at 23°C Resistant Dichloroethylene at 23°C Resistant Dichlorofluoromethane at 23°C Resistant Dichlorotetrafluoroethane at 23°C Resistant Diethyl ether at 23°C Resistant Diethylene glycol at 23°C Resistant Difluoromethane at 23°C Resistant Dimethyl acetamide at 23°C Resistant Dimethyl ether at 23°C Resistant Dimethylamine at 23°C Resistant Dimethylformamide at 23°C Resistant Dimethylsilane at 23°C Resistant Dimethylsulfoxide at 23°C Resistant Dioctyl phtalate at 23°C Resistant Dioxan at 23°C Resistant Dioxan at 60°C Resistant Diphenyl ether at 80°C Resistant Dipropyl ether at 23°C Resistant Edible fats waxs and oils at 100°C Resistant Electroplating bath (alkali) at 23°C Resistant Ethane at 23°C Resistant Ethanol at 23°C Resistant Ethyl Acetate at 23°C Resistant Ethyl chloride at 23°C Resistant Ethylene at 23°C Resistant Ethylene carbonate at 50°C Resistant Ethylene glycol at 23°C Resistant Ethylene oxide at 23°C Resistant Ethylenediamine at 23°C Resistant Fatty acids at 23°C Resistant Fatty alcohols at 23°C Resistant Fixer (photografic) at 23°C Resistant Fluorinated hydrocarbons at 70°C Resistant Formaldehyde (30% by mass) at 23°C Resistant Formamide at 23°C Resistant Fruit juices at 23°C Resistant Fuel; Diesel at 85°C Resistant Fuel; FAM 1A at 23°C Resistant Fuel; FAM 2A at 23°C Resistant Fuel; Gasoline at 85°C Resistant Furfural at 23°C Resistant Furfuryl alcohol at 23°C Resistant Glycerol at 23°C Resistant Glycols at 23°C Resistant Grease (based on metal soaps) at <100°C Resistant Grease (based on polyphenylester) at <100°C Resistant Hardening oils at 23°C Resistant Heating oils at 23°C Resistant Heptane at 23°C Resistant Hexachlorobenzene at 80°C Resistant Hexachloroethane at 23°C Resistant Hexane at 23°C Resistant Hydraulic fluids at 100°C Resistant Hydrogen at 23°C Resistant Impregnating oils at 23°C Resistant Ink at 23°C Resistant Iron(III)chloride (neutral) (10% by mass) at 23°C Resistant Isocyanates (aromatic) at 23°C Resistant Isooctane at 80°C Resistant Isopropanol at 23°C Resistant Isopropanol at 60°C Resistant Ketones (aliphatic) at 23°C Resistant Lactic acid at 10°C Resistant Lead acetate (10% by mass) at 23°C Resistant Linseed oil at 23°C Resistant Lithium hydroxide (10% by mass) at 23°C Resistant Lubricating oil (gear) at <130°C Resistant Lubricating oil (hydraulics) at <130°C Resistant Lubricating oil (transformers) at <130°C Resistant Magnesium hydroxide (10% by mass) at 23°C Resistant Magnesium salts (10% by mass) at 23°C Resistant Maleic acid (saturated) at 23°C Resistant Manganese salts (10% by mass) at 23°C Resistant Mercury at 23°C Resistant Methane at 23°C Resistant Methanol at 23°C Resistant Methyl acetate at 23°C Resistant Methyl chloride at 23°C Resistant Methyl ethyl ketone at 23°C Resistant Methyl formate at 23°C Resistant Methyl glycol at 23°C Resistant Methylamine at 23°C Resistant Methylaniline at 23°C Resistant Methylbromide at 23°C Resistant Methylpyrrolidone at 23°C Resistant Milk at 23°C Resistant n-Butyl ether at 23°C Resistant n-Butyl glycol at 23°C Resistant Naphtha at 23°C Resistant Naphthalene at 23°C Resistant Naphthenic acids at 23°C Resistant Nickel salts (10% by mass) at 23°C Resistant Nitrocellulose lacquers (non-alcoholic) at 23°C Resistant Nitrous oxide at 23°C Resistant Octane at 23°C Resistant Octene at 23°C Resistant Oil (Shell 10W40) at 23°C Resistant Oil (transformers, switchgear) at 50°C Resistant Oils (vegatable, mineral, ethereal) at 23°C Resistant Oleic acid at 23°C Resistant Paint solvents at 23°C Resistant Palmatic acid at 80°C Resistant Paraffin at 23°C Resistant Petroleum at 23°C Resistant Petroleum ether and solvents at 80°C Resistant Phosphate sol. (neutral, alkaline) (10% by mass) at 23°C Resistant Phosphine at 23°C Resistant Polyols at 23°C Resistant Potassium chloride (10% by mass) at 23°C Resistant Potassium chloride (10% by mass) at 70°C Resistant Potassium nitrate (10% by mass) at 23°C Resistant Propane at 23°C Resistant Propanol at 23°C Resistant Propene at 23°C Resistant Propionic acid (5% by mass) at 23°C Resistant Pyridine at 23°C Resistant Pyrrolidone at 23°C Resistant Rainwater (acidic) at 23°C Resistant Refrigerator oil at 23°C Resistant Road salts at 23°C Resistant Salicylic acid (saturated) at 23°C Resistant Seawater at 23°C Resistant Silane at 23°C Resistant Silicone oils at <80°C Resistant Silver nitrate (10% by mass) at 23°C Resistant Soap solution (10% by mass) at 80°C Resistant Sodium bichromate (10% by mass) at 23°C Resistant Sodium bichromate (5% by mass) at 23°C Resistant Sodium carbonate (10% by mass) at 23°C Resistant Sodium chlorate (10% by mass) at 23°C Resistant Sodium chloride (10% by mass) at 23°C Resistant Sodium chloride (saturated) at 23°C Resistant Sodium cyanide (10% by mass) at 23°C Resistant Sodium dichromate (10% by mass) at 23°C Resistant Sodium dodecylbenzenesulfonate at 23°C Resistant Sodium hydrogen carbonate (10% by mass) at 23°C Resistant Sodium hydrogen sulfate (10% by mass) at 23°C Resistant Sodium hydrogen sulfite (10% by mass) at 23°C Resistant Sodium hydroxide (10% by mass) at 23°C Resistant Sodium hypophosphite (10% by mass) at 23°C Resistant Sodium lauryl sulfate (30% by mass) at 23°C Resistant Sodium lignosulfonate at 23°C Resistant Sodium nitrilotriacetate (10% by mass) at 23°C Resistant Sodium oleate at 23°C Resistant