Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Biaxial Oriented Co-Extrusion Film Application Data

Details

Application requirements Biaxially oriented co-extrusion film Air-cooled blown co-extrusion film Deep-draw thermoforming film Material properties Slow crystallization but high end-level crystallinityBenefits

- Broader processing window for biaxial stretching film

- Thinner, stronger and lighter film with same properties

- Higher transparency multilay

Properties

- Thermal Properties

- Material Specific Properties

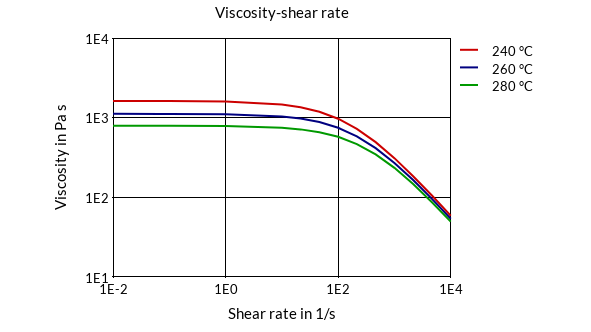

- Rheological Calculation Properties

- Other Properties

- Mechanical Properties (Film)

- Other Properties (Film)

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 218 | °C | ISO 11357-1/-3 |

| Coefficient of Linear Thermal Expansion (parallel) | 0.9 | E-4/°C | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (normal) | 0.9 | E-4/°C | ISO 11359-1/-2 |

| Value | Units | Test Method / Conditions | |

| Viscosity Number | 210 | cm³/g | ISO 307, 1157, 1628 |

| RSV Formic Acid (1g/100ml) | 3.2 | — | DSM method |

| Melt Viscosity (at 260°C) | 1120 | Pa s | DSM method |

| Value | Units | Test Method / Conditions | |

| Specific Heat Capacity | 1550 | J/(kg K) | — |

| Average Specific Heat Capacity (at 20-150°C) | 2250 | J/(kg K) | — |

| Value | Units | Test Method / Conditions | |

| Water Absorption | 9.5 | % | Sim. to ISO 62 |

| Humidity Absorption | 2.5 | % | Sim. to ISO 62 |

| Density | 1130 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Modulus of Elasticity (50 mm/min) | 450 | MPa | DSM-Method |

| Stress at Yield (parallel) | 32 | MPa | ISO 527-3 |

| Maximum Stress (parallel) | 83 | MPa | ISO 527-3 |

| Maximum Strain (parallel) | 350 | % | ISO 527-3 |

| Trouser Tear Resistance (parallel) | 32 | — | ISO 6383-1 |

| Puncture Resistance | 1300 | J/m | DSM-Method |

| Static Coefficient of Friction | 1.2 | — | ISO 8295 |

| Dynamic Coefficient of Friction | 1 | — | ISO 8295 |

| Value | Units | Test Method / Conditions | |

| Transparency/Clarity | 83 | % | DSM method |

| Oxygen Transmission Rate (at 23°C/0%r.h.) | 26 | cm³/(m²*d*bar) | DIS 15105-1/-2 |

| Oxygen Transmission Rate (at 23°C/85%r.h) | 38 | cm³/(m²*d*bar) | DIS 15105-1/-2 |

| Water Vapor Transmission Rate (at 23°C/85%r.h.) | 35 | g/(m²*d) | DIS 15106-1/-3 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Viscosity-Shear Rate

Packaging & Availability

- Packaging Type