Knowde Enhanced TDS

Identification & Functionality

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Bezels and AFL Frames Application Data

Details

Additional lighting components in Envalior EP materials: Sockets in Stanyl® PA46 or Akulon® PA6, Fog lamps in thermoconductive Stanyl or Arnite®.Benefits

- Arnite® XL allows for 40-50% lighter weight solutions versus metal

- Arnite® XL allows for reliable solutions due to its very low outgassing behavior ensuring good long term road visibility, its high dimensional stability (as compared to PA) resulting in less beam vibration (enabling switch to LED/Xenon and AFL/DBL)

- Arnite® XL allows for cost effective solutions as compared with PPS and PPA

Properties

- Mechanical Properties

- Thermal Properties

- Other Properties

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 5100 | MPa | ISO 527-1/-2 |

| Stress at Break | 57 | MPa | ISO 527-1/-2 |

| Strain at Break | 1.9 | % | ISO 527-1/-2 |

| Charpy Impact Strength (at +23°C) | 31 | kJ/m² | ISO 179/1eU |

| Charpy Notched Impact Strength (at +23°C) | 1.8 | kJ/m² | ISO 179/1eA |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 225 | °C | ISO 11357-1/-3 |

| Temperature of Deflection Under Load (1.80 MPa) | 100 | °C | ISO 75-1/-2 |

| Temperature of Deflection Under Load (0.45 MPa) | 195 | °C | ISO 75-1/-2 |

| Value | Units | Test Method / Conditions | |

| Water Absorption | 0.35 | % | Sim. to ISO 62 |

| Humidity Absorption | 0.15 | % | Sim. to ISO 62 |

| Density | 1480 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (at 270 / * °C, 2.16 / * kg) | 34 | cm³/10min | ISO 1133 |

| Molding Shrinkage (parallel) | 1.4 | % | Sim. to ISO 294-4 |

| Molding Shrinkage (normal) | 1.7 | % | Sim. to ISO 294-4 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

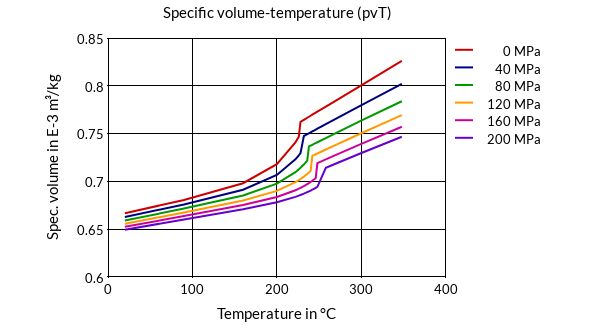

- Specific Volume-Temperature (pvT)

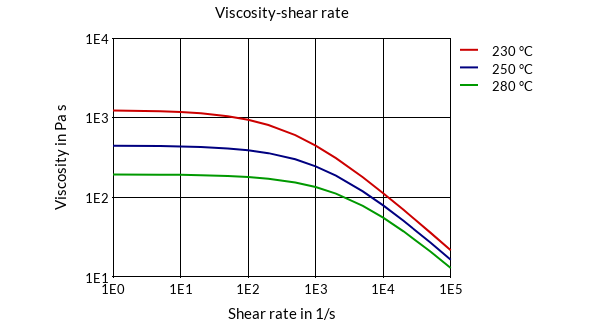

- Viscosity-Shear Rate

Packaging & Availability

- Packaging Type