Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Phone Case Application Data

Details

Product designers and manufacturers increasingly rely on thermoplastic elastomer (TPE) material solutions to produce and deliver highly durable and high-quality soft touch parts. Compared to the thermoplastic polyurethane (TPU) materials traditionally used for soft-touch manufacturing, TPEs offer better resistance to warpage and fatigue, as well as better protection against UV, chemical, and oil exposure.Benefits

- Broad tactile properties with superior touch and feel

- Broadest operating temperature range from -45°C to 150°C

- High tear and abrasion resistance

- High fatigue endurance after 255 compression cycles

- Smokable Sausage Casings Application Data

Details

Arnitel® ECO is bio-based material with up to 50% reduction in carbon footprint.Benefits

- Arnitel® TPC and Akulon® PA6 allow for reliable solutions since they yield excellent smoke penetration leading to great taste and sausage structure and high quality

- Arnitel® TPC and Akulon® PA6 allow for sustainable solutions, since they are free of substances of hazardous concerns and thus more environmentally friendly than cellulose casings

Properties

- Flame Rating

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Other Properties

- Mechanical Properties (Die Cutting)

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Flexural Modulus | 95 | MPa | ISO 178 |

| Charpy Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eA |

| Izod Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 180/1A |

| Izod Notched Impact Strength (at -30°C) | 2.6 | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 180 | °C | ISO 11357-1/-3 |

| Vicat Softening Temperature (50°C/h 50N) | 38 | °C | ISO 306 |

| Burning Behaviour (at 3.0 mm Nominal Thickness) | UL HB | class | IEC 60695-11-10 |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity | >1E13 | Ohm*m | IEC 62631-3-1 |

| Surface Resistivity | >1E15 | Ohm | IEC 62631-3-2 |

| Electric Strength | 20 | kV/mm | IEC 60243-1 |

| Value | Units | Test Method / Conditions | |

| Water Absorption in Water (at 23°C after 24h) | 0.14 | % | ISO 62 |

| Humidity Absorption | 0.03 | % | Sim. to ISO 62 |

| Density | 1140 | kg/m³ | ISO 1183 |

| Biobased Content | 43 | % (Bio C/Total C) | ASTM D6866-12 Method B |

| Value | Units | Test Method / Conditions | |

| Stress at Break (normal) | 24 | MPa | ISO 527-1/-2 |

| Strain at Break (normal) | 700 | % | ISO 527-1/-2 |

| Tear Strength (normal) | 107 | kN/m | ISO 34-1; Method B |

| Tear Strength (parallel) | 106 | kN/m | ISO 34-1; Method B |

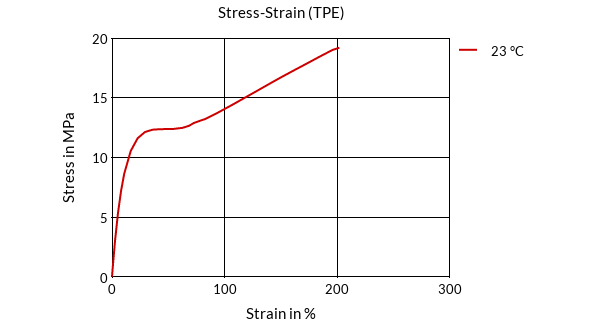

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 90 | MPa | ISO 527-1/-2 |

| Stress at 5% strain | 5.2 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 8.3 | MPa | ISO 527-1/-2 |

| Stress at 50% strain | 11 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 12 | MPa | ISO 527-1/-2 |

| Stress at Break | 17 | MPa | ISO 527-1/-2 |

| Nominal Strain at Break | 250 | % | ISO 527-1/-2 |

| Compression Set Under Constant Strain (at 70°C) | 45 | % | ISO 815 |

| Shore D Hardness (3s) | 45 | — | ISO 868 |

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (at 230 / * °C, 2.16 / * kg) | 39 | cm³/10min | ISO 1133 |

| Molding Shrinkage (parallel) | 1.3 | % | ISO 294-4 |

| Molding Shrinkage (parallel) | 1.3 | % | Sim. to ISO 294-4 |

| Molding Shrinkage (normal) | 1.5 | % | Sim. to ISO 294-4 |

| Molding Shrinkage (normal) | 1.5 | % | ISO 294-4 |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Chemical Resistance

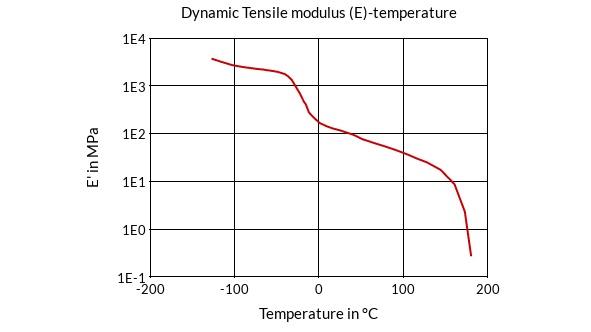

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Dynamic Tensile Modulus (E)-Temperature

- Stress-Strain (TPE)

Packaging & Availability

- Packaging Type