Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Soft Touch in Spatulas and Kitchenware Application Data

Details

Arnitel® has low viscosity grades which give excellent flow behavior for 2K-molding .Benefits

Arnitel® TPC allows for reliable solutions because of its excellent adhesion with PBT in 2K injection molding, its superb scratch resistance (which make kitchen tools look better even after years of intensive usage), its chemical resistance (dish washer proof) and its approvals for direct food contact- Wine Taps Application Data

Details

The Wine Tap is used in bag and boxed wine packaging for distributing wine.Benefits

- Arnitel® has FDA approval for high alcohol contents and single use

- Arnitel® offers good elasticity and low hysteresis, resulting in good spring characteristics

- Arnitel® has good colorability with a stable white base color

- Support Springs Application Data

Details

Low creep flexing solution for slats and mattresses, creating ultimate sleep comfort by changing durometer per section of your bed.

Benefits

- Arnitel® has high creep resistance

- Arnitel® offers a wide range of flexible products, creating the ultimate solution

- Arnitel® offers easy processing, creating design flexibility

- DC Cables Application Data

Details

DC Cables are generally used for standard electronics charging systems, like adapters. The latest designs can also be used for USB-C charging, leading to much thinner cables than AC with similar charging and safety characteristics.

Benefits

- Arnitel® has a proven track record in wire and cable, also in ultra thin cables in all application areas

- Arnitel® offers a long history in commercial production and use in major electronics OEM

- Arnitel® solutions are known to most cable extrusion companies

- Arnitel® is easy to color with consistent haptics

- Outdoor Consumer Cables Application Data

Details

Thin low voltage consumer electornics cabling, used in the outdoor environment to accommodate the use of electronics in the field, i.e. camera's, sensors etc.

Benefits

- Arnitel® Wire & Cable grades exceed the UL758 for signal, AC and DC applications

- Arnitel® offers most colors possible without strong discoloration in UV

- Arnitel® has a long track record in outdoor applications

- Phone Case Application Data

Details

Product designers and manufacturers increasingly rely on thermoplastic elastomer (TPE) material solutions to produce and deliver highly durable and high-quality soft touch parts. Compared to the thermoplastic polyurethane (TPU) materials traditionally used for soft-touch manufacturing, TPEs offer better resistance to warpage and fatigue, as well as better protection against UV, chemical, and oil exposure.Benefits

- Broad tactile properties with superior touch and feel

- Broadest operating temperature range from -45°C to 150°C

- High tear and abrasion resistance

- High fatigue endurance after 255 compression cycles

- Grips Application Data

Details

Grips are applicable to consumer appliances such as kitchenware, household utensils, hand tools, game controllers and much more. The material is usually overmolded on PC, PC/ABS or polyester.Benefits

- Arnitel® allows for excellent bonding in molding on miscellaneous in thin walls

- Arnitel® solution is dish washer proof and has good grease resistance

- Arnitel® solution offers good haptics

- Arnitel Spring in Monitor Arm Application Data

Details

Adjustable load bearing for monitor armBenefits

- Elasticity

- Low creep

- Adjustable load bearing

Properties

- Flame Rating

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Rheological Calculation Properties

- Other Properties

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Flexural Modulus | 20 | MPa | ISO 178 |

| Charpy Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eA |

| Izod Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 180/1A |

| Izod Notched Impact Strength (at -20°C) | N | kJ/m² | ISO 180/1A |

| Tensile Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 8256/1 |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 180 | °C | ISO 11357-1/-3 |

| Glass Transition Temperature (at 10°C/min) | -80 | °C | ISO 11357-1/-2 |

| Glass Transition Temperature from DMTA (tan d) | -74 | °C | ASTM D5026/D7028 |

| Coefficient of Linear Thermal Expansion (parallel) | 2.2 | E-4/°C | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (normal) | 2.2 | E-4/°C | ISO 11359-1/-2 |

| Burning Behaviour (at 1.5 mm Nominal Thickness) | UL HB | class | IEC 60695-11-10 |

| Relative Temperature Index (Electrical, 1.5 mm) | 50 | °C | UL746B |

| Relative Temperature Index (with impact, 1.5 mm) | 50 | °C | UL746B |

| Relative Temperature Index (without impact, 1.5 mm) | 50 | °C | UL746B |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity | 5E12 | Ohm*m | IEC 62631-3-1 |

| Value | Units | Test Method / Conditions | |

| Density of Melt | 905 | kg/m³ | — |

| Value | Units | Test Method / Conditions | |

| Water Absorption | 0.8 | % | Sim. to ISO 62 |

| Density | 1080 | kg/m³ | ISO 1183 |

| Apparent Density | 645 | kg/m³ | ISO 60 |

| Value | Units | Test Method / Conditions | |

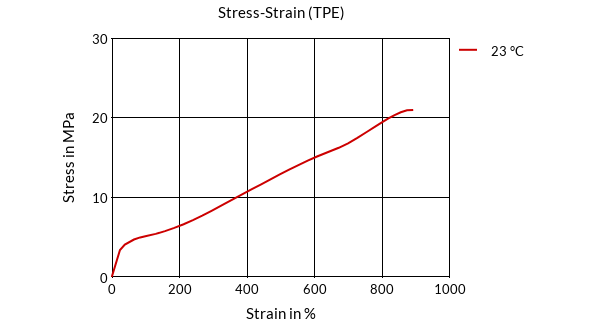

| Tensile Modulus | 25 | MPa | ISO 527-1/-2 |

| Stress at 5% strain | 1.3 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 2.1 | MPa | ISO 527-1/-2 |

| Stress at 50% strain | 4.5 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 5.1 | MPa | ISO 527-1/-2 |

| Stress at Break | 15 | MPa | ISO 527-1/-2 |

| Strain at Break | >300 | % | ISO 527-1/-2 |

| Nominal Strain at Break | 900 | % | ISO 527-1/-2 |

| Shore A Hardness (3s) | 85 | — | ISO 868 |

| Shore D Hardness (3s) | 25 | — | ISO 868 |

| Value | Units | Test Method / Conditions | |

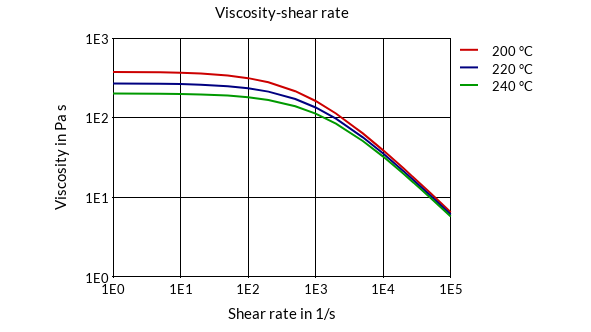

| Melt Volume-Flow Rate (at 230 / * °C, 2.16 / * kg) | 48 | cm³/10min | ISO 1133 |

| Molding Shrinkage (parallel) | 1 | % | Sim. to ISO 294-4 |

| Molding Shrinkage (normal) | 1 | % | Sim. to ISO 294-4 |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Chemical Resistance

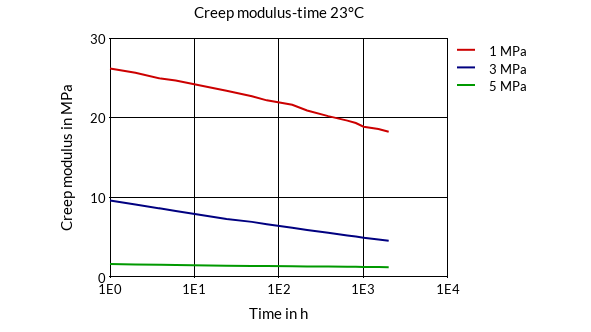

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Creep Modulus-Time 23°C

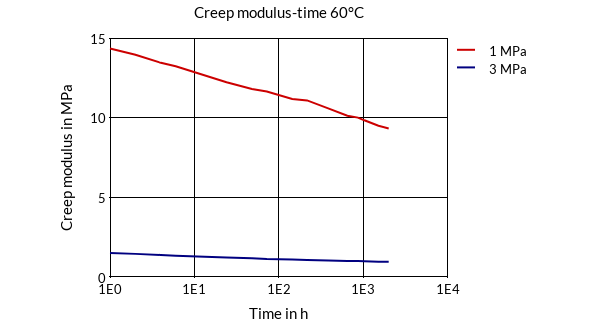

- Creep Modulus-Time 60°C

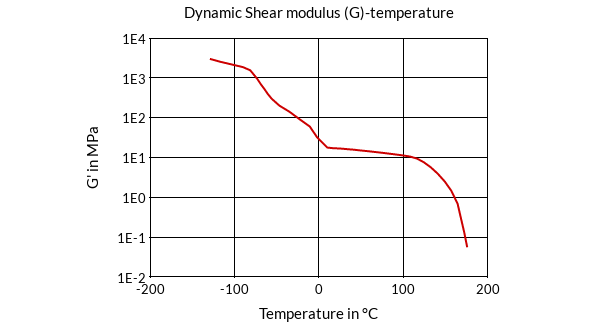

- Dynamic Shear Modulus (G)-Temperature

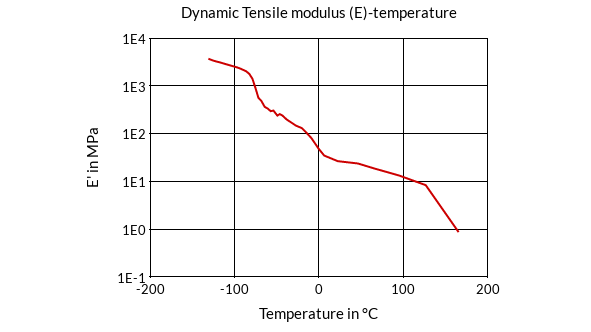

- Dynamic Tensile Modulus (E)-Temperature

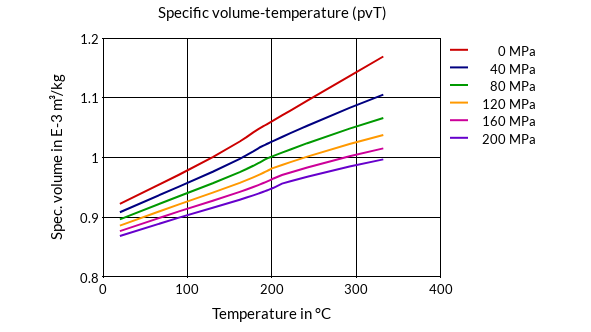

- Specific Volume-Temperature (pvT)

- Stress-Strain (TPE)

- Viscosity-Shear Rate

Packaging & Availability

- Packaging Type