Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Timing Drive Systems Application Data

Details

For more than 20 years, Envalior has helped the world’s leading automakers improve the performance and efficiency of timing chain systems, wear guide faces, support arms, and related thermoplastic components through advanced material science. Envalior offers a full portfolio of durable thermoplastic materials formulated to reduce timing chain friction and improve efficiency. To protect the environment and aid regulatory compliance, Envalior offers letters of conformity for any grades with PTFE confirming they do not contain harmful PFAS or PFOA. In addition, Envalior offers superior PTFE-free solutions with best-in-class low-friction performance such as Stanyl® HGR3.Benefits

- Stanyl® delivers best-in-class low-friction performance for improved efficiency

- Stanyl® is a proven solution used by the world’s top automakers

- All grades are PFAS and PFOA free to ensure regulatory compliance and protect the environment

- Bio-based material solutions available

- New Generation Slide Shoe Surfaces Application Data

Benefits

- Stanyl® TW371 PA46 allows for sustainable solutions (up to 1 g/km lower CO₂ emissions) because of lower friction coefficients at elevated temperatures compared to PA66

- Stanyl® TW371 PA46 allows for reliable solutions (7 times longer life time) due its higher abrasion resistance in comparison with PA66

- Stanyl® PA46 allows for cost effective solutions due to faster cycle times in comparison with PA66

- Stanyl® HGR1 produces lower frictional torque in comparison with any other material (e.g. PA66) at relatively low engine speeds ranging from idle to 1800 rpm.

- Stanyl® HGR1 also performs well at vehicle cruise speeds

- Stanyl® HGR1 will provide OEM's with a very cost-effective tool for reducing fuel consumption

- Slide Shoe Surfaces in New Generation Application Data

Details

Stanyl® TW341 is used as well for chain tensioner surfaces. Stanyl® TW441 is used also for these kind of applications.Benefits

- Stanyl® PA46 HGR2 allows for very sustainable solutions, since they enable lower frictional torque in comparison with any other material (e.g. PA66) at relatively low engine speeds ranging from idle to 1800 rpm (Stanyl® HGR2 will provide OEM's with a very cost-effective tool for reducing fuel consumption)

- Stanyl® PA46 allows for reliable solutions due to its high abrasion resistance (7 times better than PA66)

Properties

- Mechanical Properties

- Thermal Properties

- Material Specific Properties

- Other Properties

- Rheological Properties

| Value | Units | Test Method / Conditions | |

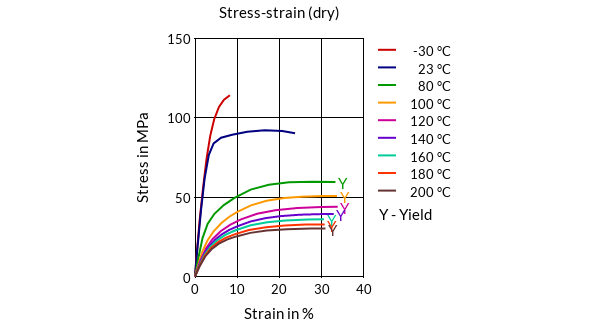

| Tensile Modulus | 3100 / 900 | MPa | ISO 527-1/-2 |

| Tensile Modulus (-40°C) | 3500 / - | MPa | ISO 527-1/-2 |

| Tensile Modulus (100°C) | 860 / - | MPa | ISO 527-1/-2 |

| Tensile Modulus (120°C) | 770 / - | MPa | ISO 527-1/-2 |

| Tensile Modulus (140°C) | 700 / * | MPa | ISO 527-1/-2 |

| Tensile Modulus (160°C) | 650 / * | MPa | ISO 527-1/-2 |

| Tensile Modulus (180°C) | 600 / * | MPa | ISO 527-1/-2 |

| Tensile Modulus (200°C) | 560 / * | MPa | ISO 527-1/-2 |

| Yield Stress | 90 / 50 | MPa | ISO 527-1/-2 |

| Yield Stress (at 100°C) | 50 / * | MPa | ISO 527-1/-2 |

| Yield Stress (at 120°C) | 45 / * | MPa | ISO 527-1/-2 |

| Yield Stress (at 160°C) | 40 / * | MPa | ISO 527-1/-2 |

| Yield Stress (at 180°C) | 35 / * | MPa | ISO 527-1/-2 |

| Yield Stress (at 200°C) | 30 / * | MPa | ISO 527-1/-2 |

| Yield Strain | 17 / - | % | ISO 527-1/-2 |

| Nominal Strain at Break (at 100°C) | >50 / * | % | ISO 527-1/-2 |

| Nominal Strain at Break (at 120°C) | >50 / * | % | ISO 527-1/-2 |

| Nominal Strain at Break (at 160°C) | >50 / * | % | ISO 527-1/-2 |

| Nominal Strain at Break (at 180°C) | >50 / * | % | ISO 527-1/-2 |

| Nominal Strain at Break (at 200°C) | >50 / * | % | ISO 527-1/-2 |

| Stress at Break | 85 / 55 | MPa | ISO 527-1/-2 |

| Stress at Break (-40°C) | 115 / - | MPa | ISO 527-1/-2 |

| Strain at Break | 25 / >50 | % | ISO 527-1/-2 |

| Strain at Break (at -40°C) | 9 / - | % | ISO 527-1/-2 |

| Flexural Modulus | 2900 / - | MPa | ISO 178 |

| Flexural Strength | 120 / - | MPa | ISO 178 |

| Charpy Impact Strength (at +23°C) | N / N | kJ/m² | ISO 179/1eU |

| Charpy Impact Strength (at -30°C) | 150 / N | kJ/m² | ISO 179/1eU |

| Charpy Notched Impact Strength (at +23°C) | 9 / 15 | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (at -30°C) | 6 / 6 | kJ/m² | ISO 179/1eA |

| Izod Notched Impact Strength (at +23°C) | 8.5 / - | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 295 / * | °C | ISO 11357-1/-3 |

| Glass Transition Temperature (at 10°C/min) | 75 / * | °C | ISO 11357-1/-2 |

| Temperature of Deflection Under Load (1.80 MPa) | 190 / * | °C | ISO 75-1/-2 |

| Temperature of Deflection Under Load (0.45 MPa) | 290 / * | °C | ISO 75-1/-2 |

| Vicat Softening Temperature (50°C/h 50N) | 290 / * | °C | ISO 306 |

| Coefficient of Linear Thermal Expansion (parallel) | 0.85 / * | E-4/°C | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (normal) | 1.1 / * | E-4/°C | ISO 11359-1/-2 |

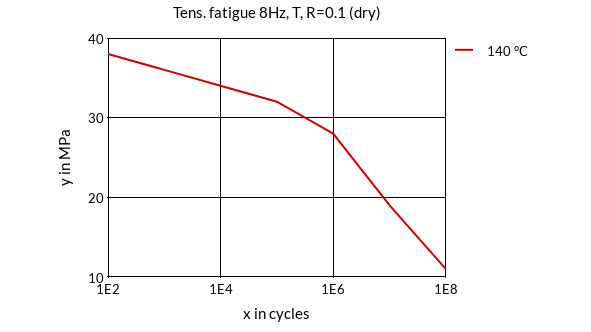

| Thermal Index (2500 hrs) | 163 / * | °C | IEC 60216/ISO 527-1/-2 |

| Thermal Index (5000 hrs) | 152 / * | °C | IEC 60216/ISO 527-1/-2 |

| Thermal Index (10000 hrs) | 141 / * | °C | IEC 60216/ISO 527-1/-2 |

| Thermal Index (20000 hrs) | 130 / * | °C | IEC 60216/ISO 527-1/-2 |

| Value | Units | Test Method / Conditions | |

| Viscosity Number | 190 / * | cm³/g | ISO 307, 1157, 1628 |

| Value | Units | Test Method / Conditions | |

| Water Absorption | 11.4 / * | % | Sim. to ISO 62 |

| Water Absorption in Water (at 23°C after 24h) | 3.3 / * | % | ISO 62 |

| Humidity Absorption | 3.2 / * | % | Sim. to ISO 62 |

| Density | 1260 / - | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Molding Shrinkage (parallel) | 2 / * | % | Sim. to ISO 294-4 |

| Molding Shrinkage (normal) | 2 / * | % | Sim. to ISO 294-4 |

| Spiral Flow Length 1.0 mm 800 bar | 115 / * | mm | — |

| Spiral Flow Length 1.0 mm 900 bar | 125 / * | mm | — |

| Spiral Flow Length 1.0 mm 1000 bar | 135 / * | mm | — |

Regulatory & Compliance

- Certifications & Compliance

- OEM Specifications

Technical Details & Test Data

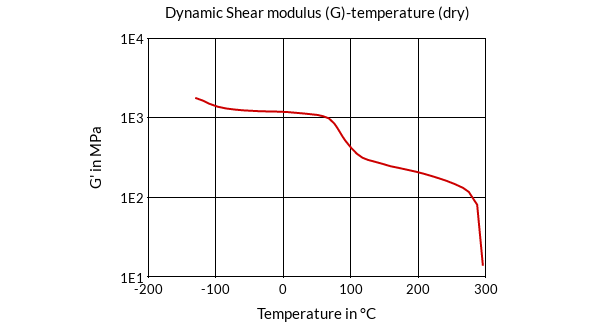

- Dynamic Shear Modulus (G)-Temperature (dry)

- Lowering Friction in Powertrain Systems by Tuning Tensioner Materials

Reduce friction in the engine and you reduce CO2 emission and improve the engine efficiency. In current chain driven valve timing systems, almost 50% of the friction losses are attributed to chain to tensioner arm and guide contacts. Friction reduction can achieve fuel savings that would require an equivalent replacement of 20 kilograms of material using ‘conventional’ metal-toplastic conversion.

A most recent result of such innovation is the Stanyl® HGR2 grade. It brings best in class friction reduction for engine oil lubricated chain guide systems. It was awarded winner in the 2017 SPE in the Materials category where it brought 0.5Nm of friction torque reduction in a V8 engine. This was equivalent to an 0.4% Fuel economy improvement.

- Friction reduction of 20% - 40% in the boundary lubrication regime compared to PA66

- This results in up to 1% fuel efficiency and thus a cost-effective solution in fulfilling CO? legislation

- Ford and other OEM's will include Stanyl® HGR2 in the options to improve the fuel economy of its future engine platforms

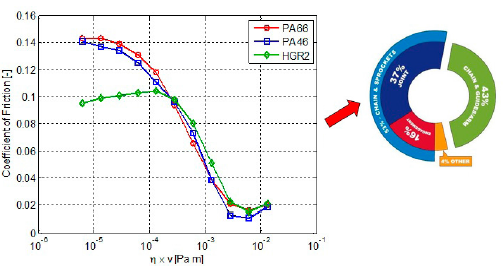

Estimating the impact of material on friction

Reducing the friction in the chain tensioner system is a complex assignment. The chain and arms take 43% of the total friction, and this friction is a depending on a variety of effects. Material selection is one, others are oil viscosity, oil additives, the temperature of the engine and the surface roughness. Based on our expertise and knowledge we

developed an analytical approach to measure, calculate and predict the effect of all these variations on the total friction. These models show that Stanyl® HGR2 enables to bring a friction reduction of 20% - 40% in the boundary lubrication regime.From lab scale to real engines

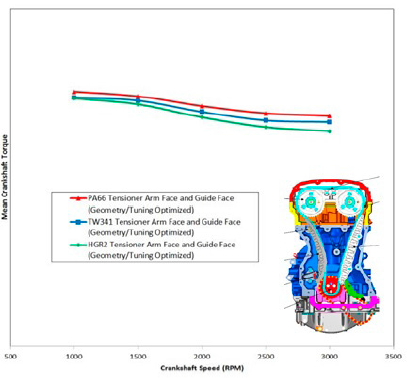

Based on motorized engine testing by BorgWarner Inc. on Ford engine timing drive and valve train, the influence of material on crankshaft torque was measured. As the graph confirms, Stanyl® HGR2 shows the lowest torque of all as measured on a real engine geometry. This directly benefits the fuel economy the complete system.

- Chemical Resistance

Chemical Type Chemical Name Resistance Other Acetaldehyde (40% by mass) at 23°C resistant Other Acetamide (50% by mass) at 23°C limited resistant, tests necessary to verify Other Acetamide (50% by mass) at >140°C not resistant Other Acetic acid (10% by mass) at 100°C not resistant Other Acetic acid (10% by mass) at 23°C limited resistant, tests necessary to verify Other Acetic acid (95% by mass) at 23°C not resistant Ketones Acetone at 23°C resistant Other Acetophenone at 23°C resistant Other Acetyl chloride at 23°C not resistant Other Acetylene at 23°C resistant Other Acrylic acid at 23°C not resistant Other Aliphatic amines at 23°C resistant Other Aliphatic hydrocarbons at 23°C resistant Other Alkylbenzenes at 23°C resistant Other Allyl alcohol at 23°C limited resistant, tests necessary to verify Other Aluminum acetate (saturated) at 23°C resistant Other Aluminum chloride (10% by mass) at 23°C resistant Other Aluminum hydroxide (saturated) at 23°C resistant Other Aluminum salts of mineral acids (saturated) at 23°C limited resistant, tests necessary to verify Other Aluminum trichloride (10% by mass) at 23°C resistant Other Amino acids (saturated) at 23°C resistant Other Ammonia at 23°C limited resistant, tests necessary to verify Other Ammonium chloride (35% by mass) at 100°C limited resistant, tests necessary to verify Other Ammonium chloride (35% by mass) at 23°C resistant Other Ammonium salts of mineral acids (10% by mass) at 23°C resistant Other Ammonium salts of mineral acids (10% by mass) at 50°C limited resistant, tests necessary to verify Other Ammonium thiocyanate (saturated) at 23°C resistant Other Amyl acetate at 100°C not resistant Other Amyl acetate at 23°C resistant Other Amyl alcohol at 23°C resistant Other Aniline at 23°C limited resistant, tests necessary to verify Other Anodizing liquid (HNO3/H2SO4) at 23°C limited resistant, tests necessary to verify Other Antimony trichoride (saturated) at 23°C not resistant Other Aqua Regia (HCl/HNO3) at 23°C not resistant Other Aromatic hydrocarbons at 23°C resistant Other ASTM 3 at 23°C limited resistant, tests necessary to verify Other Bariumsalts of mineral acids at 23°C limited resistant, tests necessary to verify Other Benzaldehyde at 23°C limited resistant, tests necessary to verify Other Benzene at 23°C resistant Other Benzene at 80°C resistant Other Benzoic acid (20% by mass) at 23°C limited resistant, tests necessary to verify Other Benzoic acid (saturated) at 23°C not resistant Other Benzyl alcohol at 23°C limited resistant, tests necessary to verify Other Beverages at 23°C resistant Other Bleaching agent (NaOCl) at 23°C not resistant Other Boric acid (10% by mass) at 23°C limited resistant, tests necessary to verify Other Boron trifluoride at 23°C not resistant Other Brake fluids (DOT 3/4) at 23°C resistant Other Bromine water (saturated) at 23°C not resistant Other Bromochlorodifluoromethane at 23°C resistant Other Bromotrifluoromethane at 23°C resistant Other Butadiene at 23°C resistant Other Butane at 23°C resistant Other Butanediols at 23°C resistant Other Butanediols at >140°C limited resistant, tests necessary to verify Other Butanols at 23°C resistant Other Butene glycol at 23°C resistant Other Butene glycol at >160°C limited resistant, tests necessary to verify Other Butene-1 at 23°C resistant Other Butter at 23°C limited resistant, tests necessary to verify Other Butyl acetate at 23°C resistant Other Butyl acrylate at 23°C resistant Other Butyl glycolate at 23°C resistant Other Butyl phthalate at 23°C resistant Other Butyric acid (20% by mass) at 23°C limited resistant, tests necessary to verify Other Butyrolactone at 23°C resistant Other Butyrolactone at >90°C limited resistant, tests necessary to verify Other Calcium chloride (10% by mass) at 100°C limited resistant, tests necessary to verify Other Calcium chloride (10% by mass) at 23°C resistant Other Calcium chloride (alcoholic) (20% by mass) at 23°C limited resistant, tests necessary to verify Other Calcium chloride (saturated) at 100°C not resistant Other Calcium chloride (saturated) at 23°C resistant Other Calcium chloride (saturated) at 60°C limited resistant, tests necessary to verify Other Calcium hydroxide (saturated) at 23°C resistant Other Calcium hypochloride (saturated) at 23°C not resistant Other Camphor (alcoholic) (50% by mass) at 23°C resistant Other Caprolactam (50% by mass) at 23°C resistant Other Caprolactam (50% by mass) at >150°C limited resistant, tests necessary to verify Other Carbon disulfide at 23°C resistant Other Carbon disulfide at 60°C not resistant Other Carbon tetrachloride at 23°C resistant Other Casein at 23°C resistant Other Chloral hydrate at 23°C not resistant Other Chloramines (10% by mass) at 23°C not resistant Other Chlorinated biphenyls at 80°C limited resistant, tests necessary to verify Other Chlorine water at 23°C not resistant Other Chloroacetic acid (10% by mass) at 23°C not resistant Other Chlorobenzene at 23°C resistant Other Chlorobenzene at 50°C resistant Other Chlorobromomethane at 23°C limited resistant, tests necessary to verify Other Chlorodifluoroethane at 23°C resistant Other Chlorodifluoromethane at 23°C resistant Other Chlorofluoroethylene at 23°C resistant Other Chloroform at 23°C not resistant Other Chlorosulfonic acid (10% by mass) at 23°C not resistant Other Chromic acid (1% by mass) at 23°C limited resistant, tests necessary to verify Other Chromic acid (10% by mass) at 23°C not resistant Other Chromyl chloride at 23°C not resistant Other cis-2-butene at 23°C resistant Other Citric acid (10% by mass) at 23°C limited resistant, tests necessary to verify Other Cobalt salt (20% by mass) at 23°C limited resistant, tests necessary to verify Other Copper sulfate (10% by mass) at 23°C resistant Other Copper(II) salt (10% by mass) at 23°C limited resistant, tests necessary to verify Other Cresols at 23°C not resistant Other Cycloalcohols (incl their esters) at 23°C resistant Other Cycloalkanes at 23°C resistant Other Cycloalkanones at 23°C resistant Other Decalin at 23°C resistant Other Developer (photografic) at 23°C resistant Other Dibutyl phthalate at 23°C resistant Other Dibutyl phthalate at 60°C resistant Other Dichlorobenzene at 23°C resistant Other Dichloroethane at 23°C resistant Other Dichloroethylene at 23°C resistant Other Dichlorofluoromethane at 23°C resistant Other Dichlorotetrafluoroethane at 23°C resistant Ethers Diethyl ether at 23°C resistant Other Diethylene glycol at 23°C resistant Other Diethylene glycol at >140°C not resistant Other Difluoromethane at 23°C resistant Other Dimethyl acetamide at 23°C resistant Other Dimethyl acetamide at >150°C not resistant Other Dimethyl ether at 23°C resistant Other Dimethylamine at 23°C resistant Other Dimethylformamide at 23°C resistant Other Dimethylformamide at 90°C limited resistant, tests necessary to verify Other Dimethylsilane at 23°C resistant Other Dimethylsulfoxide at 125°C not resistant Other Dimethylsulfoxide at 23°C resistant Other Dioctyl phtalate at 23°C resistant Other Dioxan at 23°C resistant Other Dioxan at 60°C resistant Other Diphenyl ether at 80°C resistant Other Dipropyl ether at 23°C resistant Other Edible fats waxes and oils at 100°C limited resistant, tests necessary to verify Other Electroplating bath (acidic) at 23°C not resistant Other Electroplating bath (alkali) at 23°C resistant Other Ethane at 23°C resistant Alcohols Ethanol at 23°C resistant Other Ethyl Acetate at 23°C resistant Other Ethyl chloride at 23°C resistant Other Ethylene at 23°C resistant Other Ethylene carbonate at 100°C not resistant Other Ethylene carbonate at 50°C resistant Other Ethylene chlorohydrin at 23°C limited resistant, tests necessary to verify Other Ethylene glycol at 100°C not resistant Other Ethylene glycol at 23°C resistant Other Ethylene oxide at 23°C resistant Other Ethylene oxide at >80°C not resistant Other Ethylenediamine at 23°C resistant Other Fatty acids at 23°C resistant Other Fatty alcohols at 23°C resistant Other Fixer (photografic) at 23°C resistant Other Fluorinated hydrocarbons at 70°C resistant Other Fluorine at 23°C not resistant Other Formaldehyde (30% by mass) at 23°C resistant Other Formamide at 23°C resistant Other Formamide at >150°C not resistant Other Formic acid (10% by mass) at 23°C not resistant Other Formic acid (10% by mass) at 50°C not resistant Other Fruit juices at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Fuel; FAM 1A at 23°C resistant Other Fuel; FAM 2A at 23°C limited resistant, tests necessary to verify Other Fuel; Gasoline at 85°C limited resistant, tests necessary to verify Other Fuel; LPG at 23°C limited resistant, tests necessary to verify Other Furfural at 23°C limited resistant, tests necessary to verify Other Furfuryl alcohol at 23°C limited resistant, tests necessary to verify Other Glucose at 23°C limited resistant, tests necessary to verify Other Glycerol at 170°C limited resistant, tests necessary to verify Other Glycerol at 23°C limited resistant, tests necessary to verify Other Glycolic acid (30% by mass) at 23°C limited resistant, tests necessary to verify Other Glycols at 23°C limited resistant, tests necessary to verify Other Grease (based on ester oils) at <100°C limited resistant, tests necessary to verify Other Grease (based on metal soaps) at <100°C limited resistant, tests necessary to verify Other Grease (based on polyphenylester) at <100°C limited resistant, tests necessary to verify Other Hardening oils at 23°C resistant Other Heating oils at 23°C resistant Other Heptane at 23°C resistant Other Hexachlorobenzene at 80°C resistant Other Hexachloroethane at 23°C resistant Other Hexafluoroisopropanol at 23°C not resistant Other Hexane at 23°C resistant Other Hydraulic fluids at 100°C resistant Other Hydrobromic acid (10% by mass) at 23°C not resistant Other Hydrochloric acid (10% by mass) at 23°C not resistant Other Hydrochloric acid (20% by mass) at 23°C not resistant Other Hydrochloric acid (conc.% by mass) at 23°C not resistant Other Hydrofluoric acid (40% by mass) at 23°C not resistant Other Hydrofluoric acid (5% by mass) at 23°C not resistant Other Hydrogen at 23°C resistant Other Hydrogen peroxide (0.5% by mass) at 23°C resistant Other Hydrogen peroxide (3% by mass) at 23°C not resistant Other Hydrogen peroxide (30% by mass) at 23°C not resistant Other Hydrogen sulfide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Hydroiodic acid at 23°C not resistant Other Hydroquinone (5% by mass) at 23°C not resistant Other Impregnating oils at 23°C resistant Other Ink at 23°C resistant Other Iodine (alcoholic) at 23°C not resistant Other Iron(III)chloride (acidic) (10% by mass) at 23°C not resistant Other Iron(III)chloride (neutral) (10% by mass) at 23°C limited resistant, tests necessary to verify Other Iron(III)chloride (saturated) at 23°C not resistant Other Iron(III)thiocyanate (10% by mass) at 23°C limited resistant, tests necessary to verify Other Isocyanates (aromatic) at 23°C resistant Other Isooctane at 80°C resistant Other Isopropanol at 23°C resistant Other Isopropanol at 60°C resistant Other Ketones (aliphatic) at 23°C resistant Other Lactic acid at 10°C resistant Other Lactic acid at 90°C not resistant Other Lead acetate (10% by mass) at 23°C resistant Other Linseed oil at 23°C resistant Other Lithium bromide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Lithium chloride (20% by mass) at 23°C not resistant Other Lithium hydroxide (10% by mass) at 23°C resistant Other Lithium hydroxide (10% by mass) at 80°C not resistant Other Lubricating oil (gear) at <130°C resistant Other Lubricating oil (hydraulics) at <130°C resistant Other Lubricating oil (transformers) at <130°C resistant Other Magnesium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Magnesium salts (10% by mass) at 23°C resistant Other Maleic acid (25% by mass) at 23°C limited resistant, tests necessary to verify Other Maleic acid (saturated) at 23°C resistant Other Manganese salts (10% by mass) at 23°C resistant Other Mercury at 23°C resistant Other Mercury(II)chloride (saturated) at 23°C not resistant Other Methane at 23°C resistant Alcohols Methanol at 23°C limited resistant, tests necessary to verify Other Methyl acetate at 23°C resistant Other Methyl chloride at 23°C resistant Other Methyl ethyl ketone at 23°C resistant Other Methyl formate at 23°C resistant Other Methyl glycol at 23°C resistant Other Methylamine at 23°C resistant Other Methylaniline at 23°C resistant Other Methylbromide at 23°C resistant Other Methylene chloride at 23°C limited resistant, tests necessary to verify Other Methylpyrrolidone at 23°C resistant Other Milk at 23°C limited resistant, tests necessary to verify Other n-Butyl ether at 23°C resistant Other n-Butyl glycol at 23°C resistant Other Naphtha at 23°C resistant Other Naphthalene at 23°C resistant Other Naphthalenesulfonic acids at 23°C not resistant Other Naphthenic acids at 23°C resistant Other Naphthols at 23°C not resistant Other Nickel nitrate (10% by mass) at 23°C limited resistant, tests necessary to verify Other Nickel salts (10% by mass) at 23°C resistant Other Nitric acid (2% by mass) at 23°C not resistant Other Nitric acid (conc.% by mass) at 23°C not resistant Other Nitrobenzene at 23°C limited resistant, tests necessary to verify Other Nitrobenzene at >100°C not resistant Other Nitrocellulose lacquers (alcoholic) at 23°C limited resistant, tests necessary to verify Other Nitrocellulose lacquers (non-alcoholic) at 23°C resistant Other Nitrogen oxides at 23°C limited resistant, tests necessary to verify Other Nitromethane at 23°C limited resistant, tests necessary to verify Other Nitropropane at 23°C limited resistant, tests necessary to verify Other Nitrotoluene at 23°C limited resistant, tests necessary to verify Other Nitrotoluene at >100°C not resistant Other Nitrous fumes at 23°C limited resistant, tests necessary to verify Other Nitrous oxide at 23°C resistant Other Octane at 23°C resistant Other Octene at 23°C resistant Other Oil (Burmah TAF 21) at 23°C resistant Other Oil (Castrol TAF) at 23°C resistant Other Oil (Shell 10W40) at 23°C resistant Other Oil (Shell Dexron ATF) at 23°C resistant Other Oil (Shell Spirax EP90) at 23°C limited resistant, tests necessary to verify Other Oil (transformers, switchgear) at 50°C resistant Other Oils (vegatable, mineral, ethereal) at 23°C resistant Other Oleic acid at 23°C resistant Other Oleum (H2SO4+SO3) at 23°C not resistant Other Oxalic acid (10% by mass) at 23°C limited resistant, tests necessary to verify Other Oxalic acid (10% by mass) at 80°C not resistant Other Ozone at 23°C not resistant Other Paint solvents at 23°C resistant Other Palmatic acid at 80°C resistant Other Paraffin at 23°C resistant Other Pentasin CHF 11 (S) at 23°C resistant Other Pentasin CHF 7.1 at 23°C limited resistant, tests necessary to verify Other Peracetic acid at 23°C not resistant Other Petroleum at 23°C resistant Other Petroleum ether and solvents at 80°C resistant Other Phenol (alc. sol.) (70% by mass) at 23°C limited resistant, tests necessary to verify Other Phenol (conc.% by mass) at 23°C not resistant Other Phenol at >40°C not resistant Other Phenyl ether at 23°C not resistant Other Phenyl ethyl alcohol at 23°C limited resistant, tests necessary to verify Other Phenyl ethyl alcohol at >160°C not resistant Other Phosphate sol. (neutral, alkaline) (10% by mass) at 23°C resistant Other Phosphine at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C not resistant Other Phosphoric acid (conc.% by mass) at 23°C not resistant Other Phthalic acid (saturated) at 23°C limited resistant, tests necessary to verify Other Polyols at 23°C resistant Other Potassium bromide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Potassium chloride (10% by mass) at 23°C resistant Other Potassium chloride (10% by mass) at 70°C resistant Other Potassium dichromate (5% by mass) at 23°C limited resistant, tests necessary to verify Other Potassium hydroxide (50% by mass) at 23°C limited resistant, tests necessary to verify Other Potassium nitrate (10% by mass) at 23°C resistant Other Potassium permanganate (1% by mass) at 23°C not resistant Other Potassium thiocyanate (saturated) at 23°C not resistant Other Propane at 23°C resistant Other Propanol at 23°C resistant Other Propanol at >100°C not resistant Other Propene at 23°C resistant Other Propionic acid (5% by mass) at 23°C resistant Other Propionic acid (50% by mass) at 23°C not resistant Other Pyridine at 23°C resistant Other Pyridine at 80°C limited resistant, tests necessary to verify Other Pyrrolidone at 23°C resistant Other Pyruvic acid (10% by mass) at 23°C limited resistant, tests necessary to verify Other Rainwater (acidic) at 23°C resistant Other Refrigerator oil at 23°C resistant Other Resorcinol (alcoholic) (50% by mass) at 23°C not resistant Other Road salts at 23°C resistant Other SAE 80 at 23°C resistant Other Salicylic acid (saturated) at 23°C resistant Other Seawater at 23°C resistant Other Silane at 23°C resistant Other Silicone oils at <80°C resistant Other Silicone oils at >100°C limited resistant, tests necessary to verify Other Silver nitrate (10% by mass) at 23°C resistant Other Soap solution (10% by mass) at 80°C limited resistant, tests necessary to verify Other Sodium bromide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Sodium carbonate (10% by mass) at 23°C resistant Other Sodium chlorate (10% by mass) at 23°C resistant Other Sodium chloride (10% by mass) at 23°C resistant Other Sodium chlorite (10% by mass) at 23°C limited resistant, tests necessary to verify Other Sodium cyanide (10% by mass) at 23°C resistant Other Sodium dichromate (10% by mass) at 23°C resistant Other Sodium dodecylbenzenesulfonate at 23°C resistant Other Sodium hydrogen carbonate (10% by mass) at 23°C resistant Other Sodium hydrogen sulfate (10% by mass) at 23°C resistant Other Sodium hydrogen sulfite (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Sodium hydroxide (10% by mass) at 80°C not resistant Other Sodium hydroxide (50% by mass) at 23°C not resistant Other Sodium hypochlorite (10% by mass) at 23°C not resistant Other Sodium hypophosphite (10% by mass) at 23°C resistant Other Sodium lauryl sulfate (30% by mass) at 23°C resistant Other Sodium lignosulfonate at 23°C resistant Other Sodium nitrilotriacetate (10% by mass) at 23°C resistant Other Sodium oleate at 23°C resistant Other Sodium pentachlorophenolate at 23°C resistant Other Sodium pyrosulfite (10% by mass) at 23°C resistant Other Sodium salts (nitrate, sulfate) (10% by mass) at 23°C resistant Other Soldering fluid at 23°C not resistant Other Steam at 23°C limited resistant, tests necessary to verify Other Stearate at 23°C resistant Other Stearic acid at 23°C resistant Other Styrene at 80°C resistant Other Sulfonates (10% by mass) at 23°C resistant Other Sulfur at 23°C resistant Other Sulfur dioxide (dry) at 23°C resistant Other Sulfur dioxide (moist) at 23°C limited resistant, tests necessary to verify Other Sulfur hexafluoride at 23°C resistant Other Sulfuric acid (2% by mass) at 23°C not resistant Other Sulfuric acid (conc.% by mass) at 23°C not resistant Other Sulfurous acid (saturated) at 23°C limited resistant, tests necessary to verify Other Tartaric acid (10% by mass) at 23°C resistant Other Tartaric acid (50% by mass) at 23°C limited resistant, tests necessary to verify Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Other Tetrachloroethylene at 80°C not resistant Other Tetrachloromethane at 23°C resistant Other Tetrafluoromethane at 23°C resistant Other Tetrafluoropropanol at 23°C not resistant Other Tetrahydrofuran at 23°C resistant Other Tetralin at 23°C resistant Other Tetramethylenesulfone at 23°C resistant Other Toluene at 100°C resistant Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C resistant Other Trichloroacetic acid (50% by mass) at 23°C not resistant Other Trichloroacetic acid ethyl ester at 23°C - Proven Performance in Low Wear & Friction Solutions

Timing chain:

Envalior has developed a portfolio of materials, answering every challenge in friction performance and system robustness. Various Stanyl® grades are all commercially proven solutions and have become the industry standards; 60% of the all newly built cars utilize PA46 in its timing chain system. As a recent success Stanyl® HGR2 has been chosen for low-friction slide shoes within the timing system on a new generation of energy efficient turbocharged petrol engines by Nissan, Suzuki, Ford and other OEMs. Envalior is committed to continue the development for better solutions with even lower friction that will help to further reduce CO? emissions from automobiles.

FEAD:

Stanyl® is recently introduced to the industry to replace aluminum in FEAD auto-tensioner systems – and in particular for the alternator mounted tensioner. A high strength, high stiffness and thermally conductive grade has been developed to maintain correct idler pulley alignment on the plastic tensioner arm whilst being able to heat sink the damping energy away from the friction interface. Classically sandwiched between the aluminum tensioner arm and tensioner base, Stanyl® TW371 provides the necessary wear resistance and consistent damping performance – along with excellent chemical and heat resistance in an area exposed to dirt, rain, under-the-hood liquids, and engine heat.

Gears:

Plastic actuator design is a dynamic field, where the plastic provides great design freedom, enabling gear configurations too difficult or expensive to create with metal.

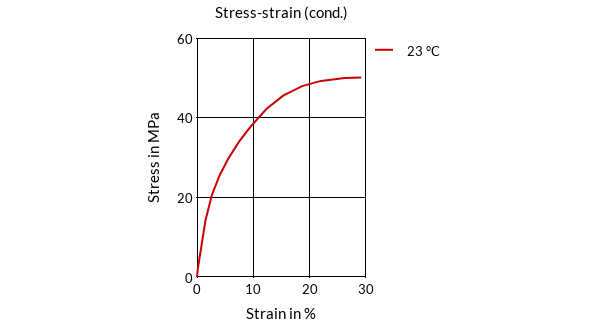

Envalior has been successfully pioneering in this field and Stanyl® is used in over 200 million vehicles worldwide in actuators such as electronic throttle control (ETC) and exhaust gas recirculation (EGR). Stanyl® offers best- inclass tribological behavior, especially at high temperatures and in dry-run, with up to 50 percent less wear than PPA, PEEK, PA66. Due to high performance of Stanyl® plastic material, cost savings can be obtained by design optimization, wall thickness reduction, but also processing optimization versus competitor plastic materials.- Stress-Strain (cond.)

- Stress-Strain (dry)

- Tensile Fatigue 8Hz, T, R=0.1 (dry)

Packaging & Availability

- Packaging Type