Knowde Enhanced TDS

Identification & Functionality

- Industrial Additives Functions

- Technologies

Features & Benefits

- Industrial Additives Features

- Key Performance Benefits

- High catalytic activity

- Excellent masterbatch stability

- Compatibility with amine co-catalysts

- Improved atmospheric stability

- Increased property performance characteristics when used in rigid and high-resiliency foams

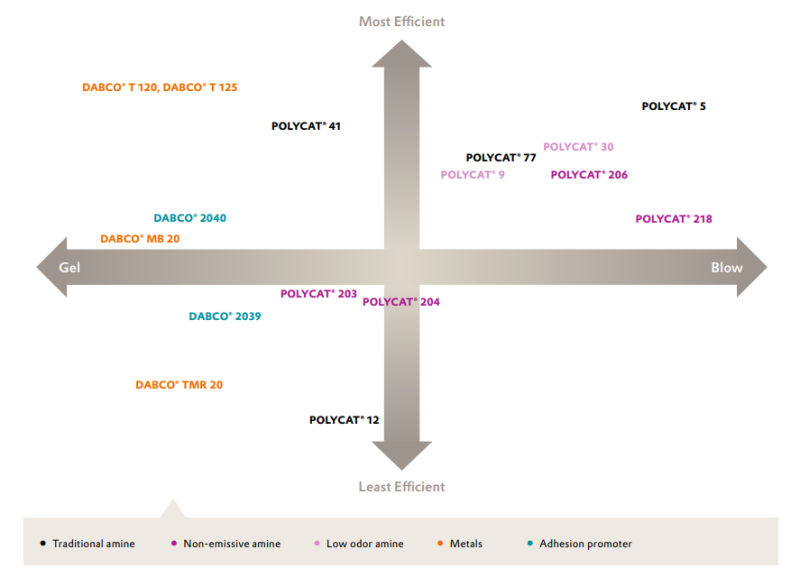

- Blow/Gel Spectrum and Catalyst Efficiency – CC SPF

Applications & Uses

- Applicable Processes

- Industrial Additives End Use

- Product Applications

- While DABCO® T 120 is recommended for general use as a rigid foam catalyst, it has been found to be particularly useful in high humidity and oxidizing environments or where improved master batch stability is necessary.

- In high-resiliency formulations, it imparts improved load-bearing properties, breathability and low compression set. Additionally, it exhibits low humid age load loss characteristics.

- It has also shown utility as a catalyst for shoe sole formulations.

- DABCO® T 120 is not compatible with bismuth catalysts.

Properties

- Physical Form

- Appearance

- Oily amber liquid

- Insoluble in

- Water

- Typical Properties

- Product Properties

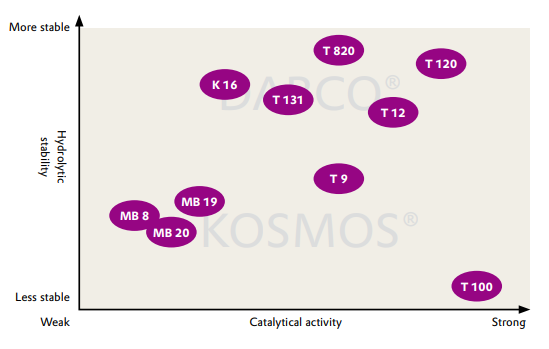

DABCO® series organotin and bismuth metal catalysts can optimize material properties and curing behavior

| Value | Units | Test Method / Conditions | |

| Flash Point | 121.0 | °C | PMCC |

| Viscosity (at 25°C) | 20.0 | mPa.s | — |

| Density (at 21°C) | 1.02 | g/cm³ | — |

| Specific Gravity (at 21°C) | 1.02 | g/cm³ | — |

| Calculated OH number | 0.0 | mg KOH/g | — |

Storage & Handling

- Shelf Life

- 12 months

- Storage Conditions

- Shelf life: minimum 12 months.

- Storage conditions: dry and cool place in factory-packed containers.

- Optimum storage temperature: 10 to 30°C.