Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- 3D Printing Material for Applications in Higher Temperature Range

- INFINAM® PA 6005 P nylon powders feature high mechanical strength as well as excellent chemical and temperature resistance. Its heat deflection temperature (HDT B) is around 195°C. Compared to other difficult-to-process materials of the polyamide 6 family, INFINAM® PA 6005 P has an impressively low water absorption rate - less than 3 percent - which has positive effects on both the processability in the 3D printing process, and the dimensional stability of the printed component.

- INFINAM® PA 6005 P is a natural colored fine powder especially for the use in additive fabrication. Our product is suitable for manufacturing of functional prototypes, manufacturing of individual units as well as serial parts. INFINAM® PA 6005 P is especially suitable for powder bed fusion technologies.

- INFINAM® PA 6005 P is a nylon powder from Evonik based on polyamide 613 and is designed for 3D printing technologies such as selective laser sintering (SLS). The polymer is produced using Evonik's own special precipitation process at the Marl Chemical Park in Germany and is suitable for 3D applications in the higher temperature range.

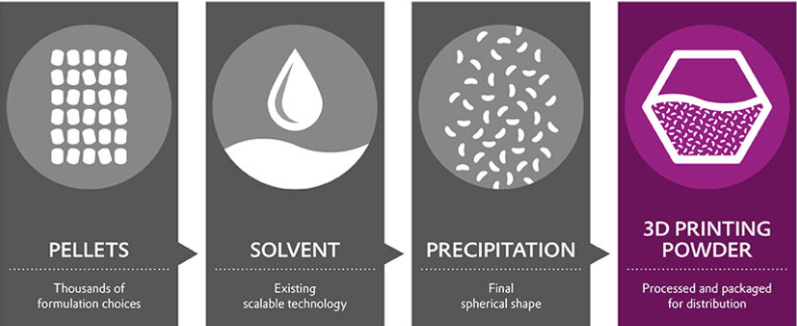

Fig. PA613 Nylon powders manufactured in Evonik's own process

- Precipitation is a purely physical process that Evonik uses on a large scale for its powder production. Polyamide 613 granules are dissolved in a suitable solvent under defined pressure and temperature, and the resulting solution is then subjected to an equally controlled cooling process. During this process, the solvent separates again from the polymer, and the latter precipitates to form a fine powder of Evonik's INFINAM® PA613 branded 3D printing nylon material.

Properties

- Color

- Physical Form

- Printed Part Properties

- Powder Characteristics

- Note

- X, Y, Z - Specimens printed on XYZ axis

| Value | Units | Test Method / Conditions | |

| Tensile Modulus (flat X) | 2000.0 | MPa | ISO 527 |

| Tensile Modulus (on-edge Y) | 2000.0 | MPa | ISO 527 |

| Tensile Modulus (upright Z) | 2000.0 | MPa | ISO 527 |

| Tensile Strength (flat X) | 57.0 | MPa | ISO 527 |

| Tensile Strength (on-edge Y) | 57.0 | MPa | ISO 527 |

| Tensile Strength (upright Z) | 55.0 | MPa | ISO 527 |

| Nominal Strain (at break flat X, εtB) | 34.0 | % | ISO 527 |

| Nominal Strain (at break on-edge Y, εtB) | 34.0 | % | ISO 527 |

| Nominal Strain (at break upright Z, εtB) | 29.0 | % | ISO 527 |

| Value | Units | Test Method / Conditions | |

| Bulk Density (Powder, dry/cond) | 450.0 | g/l | EN ISO 60 |

| Density (dry/cond) | 1050.0 | kg/m³ | ISO 1183 |

| Particle Size (dry/cond) | 60.0 | μm | ISO 13320, DIN ISO 8130-13 |

| Melting Tempemperature (1st heating, powder, dry/cond) | 215.0 | °C | ISO 11357 |