Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- Ultra High Tensile Toughness + Excellent Ductility

- Moderate Heat Deflection Temperature

- Excellent Surface Finish

- Machinable

- Able to resolve features as small as 0.2mm

- Compatible with a variety of vat photopolymerization technologies

Suitable For:

- End-Use Parts (PP-Like)

- Designer Toys

- Snap-Fit Objects

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Application Information

Print settings

- INFINAM® TI 5400 L is designed to print on bottom-up digital light processing (DLP) machines.

- When printing with a light intensity of 2.4 mW/cm2 at 405 nm, the recommended layer exposure time for 100 μm thick layers is 2.4 s.

- Working curve data for 405 nm wavelength and 2.4 mW/cm2 intensity: Critical exposure energy Ec = 2.0-2.5 mJ/cm2 and Depth of penetration Dp = 200-250 μm.

Washing procedure

- It is recommended to wash printed parts with tripropylene glycol methyl ether (TPM) to remove uncured resinous materials.

- Recommend wash cycle: use 2 to 3 rinse buckets (from dirty soak to clean soak), each rinse for 2 to 5 minutes.

- Lastly, wash the 3D-printed object with isopropanol (IPA) for 2 minutes to remove excess TPM.

- After IPA wash, allow parts to dry for at least 30 minutes in order for the IPA to fully evaporate before the next post-curing process.

- Over-soaking or over-washing may result in loss in the mechanical properties.

- When support structures are used, they should be removed before postcuring.

Post-curing procedure

- After washing, the parts should be submitted to ultraviolet (UV) light (intensity at ca. 5 mW/cm2) for 120 min at 80 °C, followed by 180 min at 80 °C without UV light.

Properties

- Color

- Physical Form

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Test Conditions

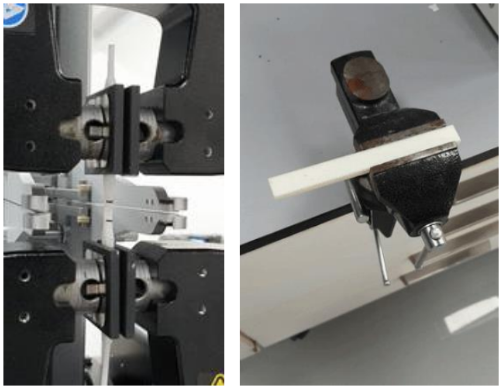

Mechanical testing measurements

- The mechanical values reported in this document were obtained on specimens printed with a DLP printer at 405 nm (2.4 mW/cm2, XY or XZ print with 2.4 s layer exposure time, 100 μm thick layers).

- Tensile bars were tested following ASTM D638, Type V, 10 mm/min using an automated extensometer.

- Specimens are notched using a manual notching machine.

Statement on reported mechanical and thermal properties

- The mechanical and thermal values reported in this document derived from printing various parts with one specific bottom-up DLP machine and following the above-mentioned procedures.

- Those values reflect an approximation of the mean value of a range of values and are intended for reference and comparison purposes only.

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 1500 | MPa | ASTM D638 |

| Ultimate Tensile Strength | 40 | MPa | ASTM D638 |

| Elongation (at Break) | 210 | % | ASTM D638 |

| Flexural Modulus | 1080 | MPa | ASTM D790 |

| Flexural Stress (at 5% Strain) | 44 | MPa | ASTM D790 |

| Izod Notched Impact | 27 | J/m | ASTM D256 |

| Value | Units | Test Method / Conditions | |

| Liquid Density (at 25°C) | 1.07 | g/cm³ | ASTM D4052 |

| Liquid Viscosity (at 25°C, 1 Hz) | 1130 | mPa.s | ASTM D4287 |

| Shore D Hardness | 80 | — | ASTM D2240 |

| Water Absorption (24 h) | 5.4 | % | ASTM D570 |

| Value | Units | Test Method / Conditions | |

| Heat Deflection Temperature (0.455 MPa) | 56 | °C | ASTM D648 |

| Glass Transition Temperature (tan δ) | 101 | °C | ASTM D4065 |

Technical Details & Test Data

- Advanced Material Performance

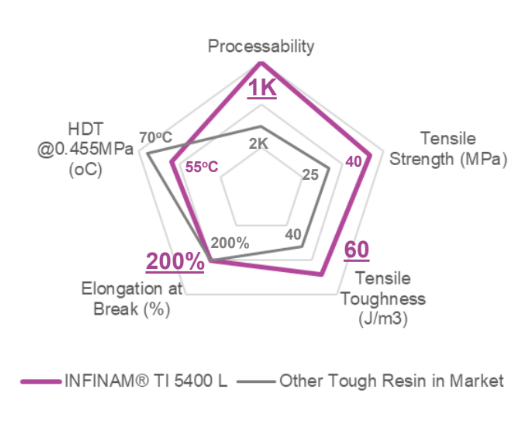

Fig 1.Setting new benchmark for ultra-high toughness and high ductility plastic.

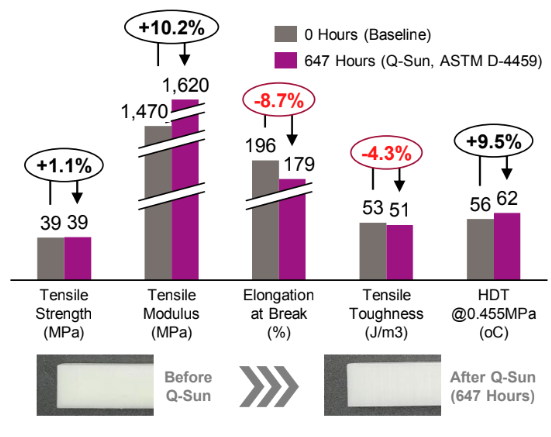

Fig 2. Properties retained after accelerated indoor aging.

Fig 3. Materials can withstand repetitive impact.

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage and Handling Information

- INFINAM® TI 5400 L resin is a light-sensitive product protected by its original packaging.

- Exposure of the liquid formulation to daylight or UV light should be minimized or avoided at all during storage and handling to ensure consistent print quality.

- Special light sources shall be used instead.

- Store product in a dry location with optimum storage temperature of 10-30 °C.

- Storage beyond this recommended temperature range can adversely affect both print and product properties.

- It is recommended to shake INFINAM® TI 5400 L resin well before use.

- Degassing can be carried out before any print process.

- It is advisable not to store the unused resin in the vat, especially for prolonged period of usage.

- If the resin is left in the vat after printing, thoroughly mix and agitate the resin in the vat prior to any print processes.

- Do not return used resin from the vat back into the original INFINAM® TI 5400 L container.