Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Directions for Use

- Recommended print settings

INFINAM® RG 2000 L is designed to print on bottom-up digital light processing (DLP) machines. When printing with a light intensity of 9 mW/cm² at 385 nm, the recommended layer exposure time for 100 μm thick layers is 2 s, with a base layer exposure time of 3 s. Working curve data for 385 nm wavelength and 9 mW/cm². Intensity: Critical exposure energy Ec = 6 - 9 mJ/cm² and Depth of penetration Dp = 300 - 400 μm.

- Recommended washing procedure

It is recommended to wash printed parts with isopropanol to remove uncured resin. When support structures are used, they should be removed before post-curing. To achieve higher clarity in complex geometry objects, it is recommended to wash the parts in tripropylene glycol methyl ether. When support structures are used, they should be removed before postcuring.

- Recommended post-curing procedure

After washing, the parts should be submitted to ultraviolet (UV) light (intensity at ca. 5 mW/cm²) for 120 min at 80°C, followed by 180 min at 80°C without UV light.

Properties

- Color

- Physical Form

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Optical Properties

- Note

¹ - The mechanical values were obtained on specimens printed with a DLP printer at 385 nm (9 mW/cm², XY or XZ print with 2 s layer exposure time, 100 μm thick layers). Tensile bars were tested following ASTM D638, Type V, 10 mm/min using an automated extensometer. Specimens are notched using a manual notching machine.

² - The mechanical and thermal values reported in this document derived from printing various parts with one specific bottom-up DLP machine and following the above-mentioned procedures. Those values reflect an approximation of the mean value of a range of values and are intended for reference and comparison purposes only.

| Value | Units | Test Method / Conditions | |

| Tensile Modulus ¹ ² | 1940.0 | MPa | ASTM D638 |

| Ultimate Tensile Strength ¹ ² | 53.0 | MPa | ASTM D638 |

| Elongation at Break ¹ ² | 48.0 | % | ASTM D638 |

| Flexural Modulus ¹ ² | 1900.0 | MPa | ASTM D790 |

| Flexural Stress at 5% Strain ¹ ² | 80.0 | MPa | ASTM D790 |

| Izod Notched Impact ¹ ² | 44.0 | J/m | ASTM D256 |

| Value | Units | Test Method / Conditions | |

| Liquid Density (at 25°C) | 1.03 | g/cm³ | ASTM D1475 |

| Liquid Viscosity (at 25°C/1 Hz) | 3060.0 | mPa.s | ASTM D4287 |

| Shore D Hardness | 85.0 | — | ASTM D2240 |

| Water Absorption (for 24 h) | 0.36 | % | ASTM D570 |

| Value | Units | Test Method / Conditions | |

| Heat Deflection Temperature (at 0.455 MPa) ² | 78.0 | °C | ASTM D648 |

| Glass Transition Temperature (tanδ) ² | 107.0 | °C | ASTM D4065 |

| Value | Units | Test Method / Conditions | |

| Transmittance | 98.0 | % | ASTM E1348 |

| Haze (C) | 68.0 | — | ASTM D1003 |

| L* | 99.04 | — | ASTM E1348 |

| a* | 0.24 | — | ASTM E1348 |

| b* | 1.01 | — | ASTM E1348 |

| C* | 1.04 | — | ASTM E1348 |

| h (C) | 76.49 | — | ASTM E1348 |

Technical Details & Test Data

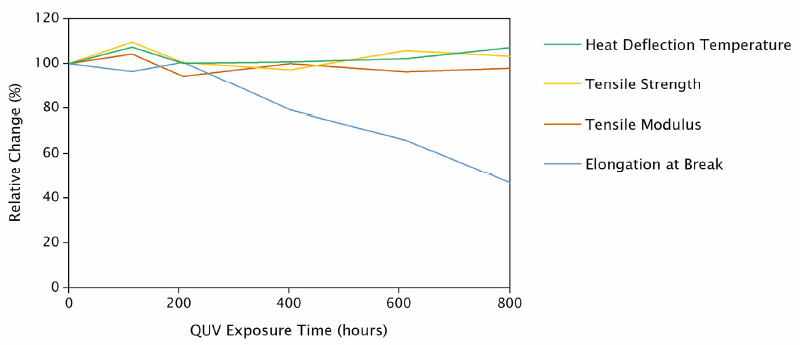

- Accelerated Outdoor Weathering

Thermal and mechanical properties (ASTM G154 Cycle 1, QUV):

Optical properties (ASTM G154 Cycle 1, QUV):

QUV Exposure Time (hours) L* a* b* Haze (C) 0 100.72 0.52 1.44 86.62 115 100.53 0.37 2.09 86.49 208 100.54 0.4 1.96 86.62 402 100.5 0.45 1.83 87.24 612 100.5 0.47 1.78 86.58 800 100.67 0.5 1.73 86.88

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage and Handling Information

- INFINAM® RG 2000 L resin is a light-sensitive product protected by its original packaging. Exposure of the liquid formulation to daylight or UV light should be minimized or avoided at all during storage and handling to ensure consistent print quality. Special light sources shall be used instead.

- Store product in a dry location with optimum storage temperature of 10 - 30 °C. Storage beyond this recommended temperature range can adversely affect both print and product properties.

- It is recommended to shake INFINAM® RG 2000 L resin well before use. Degassing can be carried out before any print process. It is advisable not to store the unused resin in the vat, especially for prolonged period of usage.

- If the resin is left in the vat after printing, thoroughly mix and agitate the resin in the vat prior to any print processes. Do not return used resin from the vat back into the original INFINAM® RG 2000 L container.