Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Key Features

TROGAMID® CX7323, in which up to 100% of fossil raw materials are replaced by bio-circular feedstocks.

Filigree:- High elastic modulus

- Flowability

Light colors:

- No yellowness

- > 90% transparency

Ultra-strong:

- High fatigue resistance

- High impact resistance

Easy to clean:

- Microcrystallinity

- Smooth surface

Medium viscosity

- Permanently transparent

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Product Applications

- Filigree and fatigue- resistant frames

- Impact demanding frames of sport glasses

Properties

- Color

- Flame Rating

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

- Rheological Calculation Properties

- Test Specimen Production

- Rheological Properties

- Burn Testing Properties

- Notes

N = No break

C = Complete break

Pigmentation can affect values.

| Value | Units | Test Method / Conditions | |

| Tensile Modulus (dry) | 203000 | psi | ISO 527 |

| Tensile Strength (dry) | 8700 | psi | ISO 527 |

| Yield Stress (dry) | 8700 | psi | ISO 527 |

| Yield Strain (dry) | 8 | % | ISO 527 |

| Stress at 50% Strain (dry) | 5800 | psi | ISO 527 |

| Stress at Break (dry) | 8700 | psi | ISO 527 |

| Nominal Strain at Break (ɛtb, dry) | 160 | % | ISO 527 |

| Tensile Creep Modulus (0.5% Strain, 1h, cond.) | 189000 | psi | ISO 899-1 |

| Tensile Creep Modulus (0.5% Strain, 1000h, cond.) | 102000 | psi | ISO 899-1 |

| Charpy Notched Impact Strength (+23°C , dry) | 5.23 | ftlb/in² | ISO 179/1eA |

| Charpy Notched Impact Strength (0°C, dry) | 5.71 | ftlb/in² | ISO 179/1eA |

| Charpy Notched Impact Strength (-30°C, dry) | 5.23 | ftlb/in² | ISO 179/1eA |

| Flexural Modulus (23°C, dry) | 247000 | psi | ISO 178 |

| Flexural Stress at Conv. Deflection (23°C, dry) | 7250 | psi | ISO 178 |

| Flexural Strength (23°C, dry) | 13100 | psi | ISO 178 |

| Flexural Strain at Flexural Strength (23°C, dry) | 9 | % | ISO 178 |

| Pressure Cycle Test on Hollow Part (dry) | 200000 | cycles | EN 13443-1 |

| Taber Abrasion Resistance (S33, 2x 500g, dry) | max. 25 | mg/100 cycles | DIN 53754 |

| Value | Units | Test Method / Conditions | |

| Density (dry) | 1.02 | g/cm³ | ISO 1183 |

| Water Absorption (dry) | 3.5 | % | Sim. to ISO 62 |

| Humidity Absorption (dry) | 1.5 | % | Sim. to ISO 62 |

| Shore D Hardness (dry) | 81 (3 sec) | — | ISO 7619-1 |

| Ball Indentation Hardness (dry) | 16000 | psi | ISO 2039-1 |

| Density | 1.02 | g/cm³ | ASTM D 792 |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (dry) | 482 | °F | ISO 11357-1/-3 |

| Glass Transition Temperature (dry) | 284 | °F | ISO 11357-1/-2 |

| Temperature of Deflection Under Load A (1.80 Mpa, dry) | 226 | °F | ISO 75-1/-2 |

| Temperature of Deflection Under Load B (0.45 Mpa, dry) | 252 | °F | ISO 75-1/-2 |

| Vicat Softening Temperature A (10 N, 50 K/h, dry) | 279 | °F | ISO 306 |

| Vicat Softening Temperature B (50 N, 50 K/h, dry) | 266 | °F | ISO 306 |

| Coefficient of Linear Thermal Expansion (23°C to 55 °C, Parallel, dry) | 5.0e-05 | in/in/°F | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (23°C to 55 °C, Normal, dry) | 5.0e-05 | in/in/°F | ISO 11359-1/-2 |

| Melting Temperature | 482 | °F | ASTM D 3418 |

| Value | Units | Test Method / Conditions | |

| Surface Resistance (RSA, dry) | 10000000000000 | Ohm | IEC 62631-3-2 |

| Surface Resistivity (σA, dry) | 100000000000000 | Ohm/sq | IEC 62631-3-2 |

| Value | Units | Test Method / Conditions | |

| Density of Melt | 56.2 | lb/ft³ | — |

| Thermal Conductivity of Melt | 1.73 | BTU in/(hr ft² °F) | — |

| Specific Heat Capacity Melt | 0.936 | BTU/(Ib-F) | — |

| Effextive Thermal Diffusivity | 1.12e-07 | m/s | — |

| Ejection Temperature | 212 | °F | — |

| Minimum Mold Temperature | 140 | °F | — |

| Maximum Mold Temperature | 212 | °F | — |

| Minimum Melt Temperature | 536 | °F | — |

| Maximum Melt Temperature | 572 | °F | — |

| Value | Units | Test Method / Conditions | |

| Injection Molding - Melt Temperature | 536 | °F | ISO 294 |

| Injection Molding - Mold Temperature | 176 | °F | ISO 294 |

| Injection Molding - Injection Velocity | 7.87 | in/s | ISO 294 |

| Injection Molding - Pressure at Hold | 10200 | psi | ISO 294 |

| Value | Units | Test Method / Conditions | |

| Melt Volume Flow Rate (dry, at 536°F, 4.76lb) | 8.2 | cm³/10min | ISO 1133 |

| Molding Shrinkage (Parallel, dry) | 0.7 | % | ISO 294-4, 2577 |

| Molding Shrinkage (Normal, dry) | 0.8 | % | ISO 294-4, 2577 |

| Mold Temperature (dry) | 176 | °F | — |

| Melt Temperature (dry) | 536 | °F | — |

| Value | Units | Test Method / Conditions | |

| Burning Behavior (at 1.5 mm Nominal Thickness) (dry) | HB | class | IEC 60695-11-10 |

| Burning Behavior (at Thickness 0.1181 in.) (dry) | HB | class | IEC 60695-11-10 |

| Burning Behavior (at Thickness 0.03151 in.) (dry) | HB | class | IEC 60695-11-10 |

| Burning Behavior (at Thickness 0.0157 in.) (dry) | HB | class | IEC 60695-11-10 |

| Glow Wire Flammability Index (at Thickness 0.0394 in.) | 1760 | °F | IEC 60695-2-12 |

| Glow Wire Ignition Temperature (at Thickness 0.0394 in.) | 1470 | °F | IEC 60695-2-13 |

| Volume Resistivity (pV, dry) | min. 1E13 | Ohm*m | IEC 62631-3-1 |

| Surface Resistivity (σE, cond.) | 1613 | Ohm | IEC 62631-3-2 |

| Relative Permittivity (100Hz, dry) | 3.6 | — | IEC 62631-2-1 |

| Relative Permittivity (1MHz, dry) | 3.2 | — | IEC 62631-2-1 |

| Dissipation Factor (100Hz, dry) | 115 | E-4 | IEC 62631-2-1 |

| Dissipation Factor (1Mhz, dry) | 325 | E-4 | IEC 62631-2-1 |

| Electric Strength (AC, S20/S20, t. 1 mm, dry.) | 686 | kV/in | IEC 60243-1 |

| Comparative Tracking Index (Test Solution A, 50 Drops Value, dry) | 600 | — | IEC 60112 |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Test Data

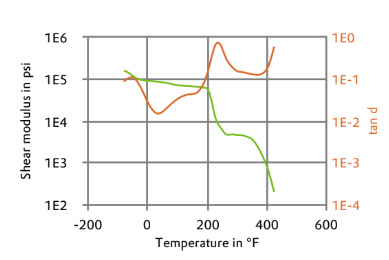

Dynamic Shear modulus-temperature (dry)

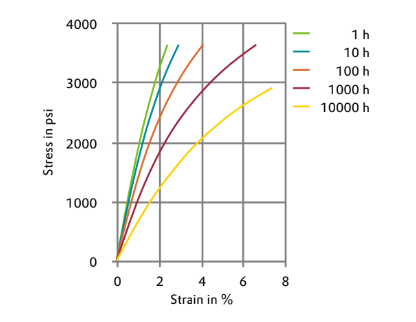

Stress-strain (isochronous) 73°F (dry)

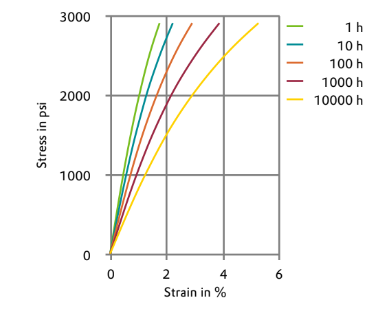

Stress-strain (isochronous) 104°F (dry)

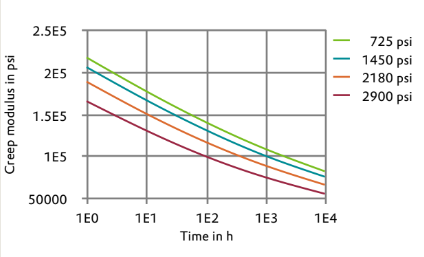

Creep modulus-time 104°F (dry)

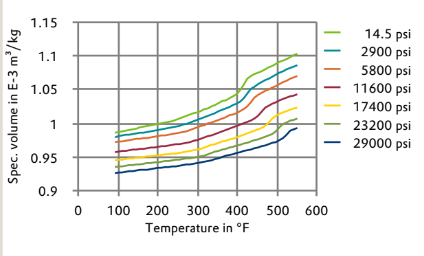

Specific volume-temperature (pvT)

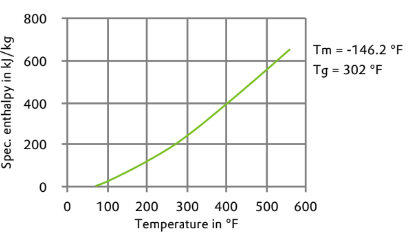

Spec. enthalpy/mass-temp. (DSC)

Packaging & Availability

- Packaging Information

TROGAMID® CX7323 are supplied as spherical pellets in moisture-proof packaging ready for processing.