Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Attributes

- Superior reflow characteristics.

- Environmentally stable - long stencil life.

- Excellent print characteristics.

Applications & Uses

- Applications

- Application Area

- Cleaning

Raw solder paste can be removed from the stencil, squeegee blades, and circuit boards using a variety of commercial cleaners. Isopropyl alcohol (IPA) can also be used.

WS890 flux residues are corrosive and must be removed using a suitable wash process. It is recommended to remove WS890 flux residues within 4 hours after soldering using D.I. water heated to 100 - 180°F in standard washing equipment. It is possible to wash away WS890 flux residues after multiple heat cycles followed by a 24 hour hold time, although this is not recommended.

Properties

- Physical Form

Technical Details & Test Data

- WS890 with Solder Alloy

Solder Alloy Solder Powder Size Availability

(IPC J-STD-005)Melting Range (°C) SAC305 Type 3 or 4 217 - 220 SN100C (Nihon Superior) Type 3 or 4 227 SN100CV (Sn/Cu/Ni/Bi)

(Nihon Superior)Type 3 or 4 221 - 225 Sn/Ag 3.5% Type 3 221 LF-C2 (Nihon Superior) Type 3 or 4 208 - 213 Anti-tombstoning mixtures Type 3 or 4 Range depends on the mixture - Other sizes of solder powder are available upon request.

- The size range for the solder powder types are as follows:

- Type 3 (25-45 μm >80%). Mesh -325/+500

- Type 4 (20-38 μm >80%). Mesh -400/+635

- Type 5 (15-25 μm >80%). Mesh -500/+800

- Compatible Products

- 150N, 152N, 159HF liquid fluxes.

- WS890 gel flux.

- Technical Details

Print Parameter Preferred Acceptable Solder paste bead size 1.5 to 2.0 cm (0.60 to 0.80 in) 1.0 to 2.5 cm (0.40 to 1.0 in) Squeegee blade Fine grain stainless steel. 60°

from horizontal. 45° from

horizontal for pin in paste.Any type of stainless steel Stencils Fine grain (2-5 µm) or ultra-fine

grain (1-2 µm) stainless steelAll types of commercially

available stencilsPrint speed 30 to 100 mm/sec (1.2 to 4.0

in/sec)20 to 200 mm/sec (0.8 to 8.0

in/sec)Pressure / blade length

(increase with increasing speed)0.27 to 0.36 kg/cm (1.5 to 2.0

lbs/in)0.27 to 0.54 kg/cm (1.5 to 3.0

lbs/in)Separation speed 1.0 to 5.0 mm/sec 0.5 to 10.0 mm/sec Underside stencil cleaning Wet / vacuum / vacuum cycle

every 1-5 printsOther cleaning cycles every 1 to

20 prints depending upon

technologyStencil life 8 hours at 18-29°C (65-85°F)

and 10-70% RH.Stencil life may be shorter

outside of the preferred

conditions.- Blade pressure should be set as low as possible to clean off the stencil. Higher blade pressures will increase stencil and blade wear, and can lead to “scooping” and other print defects.

- Underside stencil cleaning is best accomplished with commercial cleaners and high quality wipe materials. Nano-coated stencils can be used to reduce the frequency of underside cleaning.

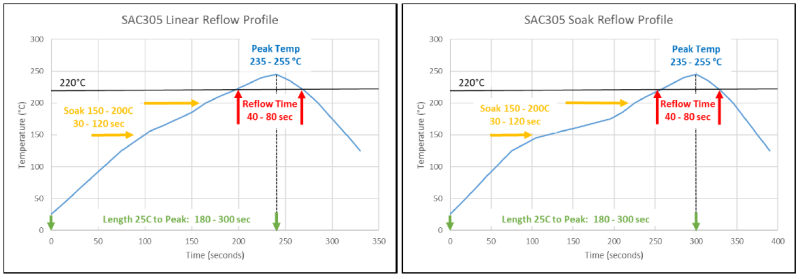

Reflow Parameter Preferred Acceptable Profile length

(25 °C to peak)3.5 to 4.5 min (210 to 270 sec) 3.0 to 5.0 min (180 to 300 sec) Heating ramp rate

(20 second window)1.0 to 2.0°C/sec 1.0 to 3.0°C/sec Preheat / soak time

(150 - 200 °C)60 to 90 sec 30 to 120 sec Peak temperature 240 to 250°C for SAC alloys

245 to 255°C for SN100C235 to 255°C for SAC alloys

240 to 260°C for SN100CReflow time

(time above liquidus)50 to 70 sec 40 to 80 sec Cooling ramp rate

(20 second window)3.0 to 6.0°C/sec 1.0 to 6.0°C/sec - Reflow time should be calculated based on the liquidus point of the alloy used: SN100C = 227°C, SN100CV = 225°C, SAC305 = 220°C, Sn96.5/Ag3.5 = 221°C, LF-C2 = 213°C.

Example reflow profile graphs are shown below. These are a good starting point but they can be modified to fit the product and process. Contact FCT Assembly for assistance with reflow profiling.

Safety & Health

- Safety

Wear chemically resistant gloves when handling solder paste. Avoid breathing fumes, especially during reflow of the solder paste.

J-STD-004B Flux Standard Test Method Result J-STD-004B classification J-STD-004B methods ORH1 Halide ion content (Br- , Cl- , F- , I- ) IPC 2.3.28.1 1.7 to 1.8% wt of solids Halogen content (Br and Cl) EN 14582, IPC 2.3.28.1 6.8 to 7.2% wt of solids Halide by silver chromate IPC 2.3.33 Halides detected Fluoride by spot test IPC 2.3.35.1 None detected Copper mirror IPC 2.3.32 High activity Copper corrosion IPC 2.6.15 Corrosion present Surface Insulation Resistance (SIR) IPC 2.6.3.7 Pass > 1.00E+08 ohms Electro Chemical Migration (ECM) IPC 2.6.14.1 Pass, increase of 1.5 Log_{10} ohms J-STD-005 Solder Paste Standard Test Method Result Viscosity - Brookfield IPC 2.4.34 Refer to the C of A Slump - frosted glass IPC 2.4.35 Pass Solder balling - frosted glass IPC 2.4.43 Preferred Wetting - copper IPC 2.4.45 Pass

Packaging & Availability

- Packaging Type

- Solder Paste Packaging

Solder Paste Packaging Net Weight (grams) Jars 250, 500 Cartridges 500 or 600 (6 oz), 700 (8 oz), 1300 (12 oz) Syringes 30, 100 Enclosed print systems 800

Storage & Handling

- Storage and Handling

Best practices for storage and handling of solder paste are listed below.

- Shelf life is 9 months when stored at 0 to 10°C (32 to 50°F).

- Warm the solder paste to room temperature (18 to 29°C / 65 to 85°F) before use. Do not force warming by heating the solder paste. Keep the solder paste sealed while warming, which typically takes 3 to 4 hours at room temperature. Warming overnight is acceptable.

- Ideally solder paste should be mixed before use to bring it to a normal working consistency. This can be done by hand-stirring in a jar, or using a knead cycle on the printer.

- Best practice is to keep the solder paste at room temperature until completely used. Remaining fresh solder paste should be sealed in the original container along with all inserts, lids, etc.

- If solder paste is removed from the printer and stored, it is recommended to store it in a separate container from the fresh solder paste. The container should be sealed with all inserts, lids, etc.

- Once solder paste is applied to the circuit board, the best practice is to reflow the solder paste as soon as possible. It is acceptable to reflow within approximately 8 hours.