Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Product Highlights

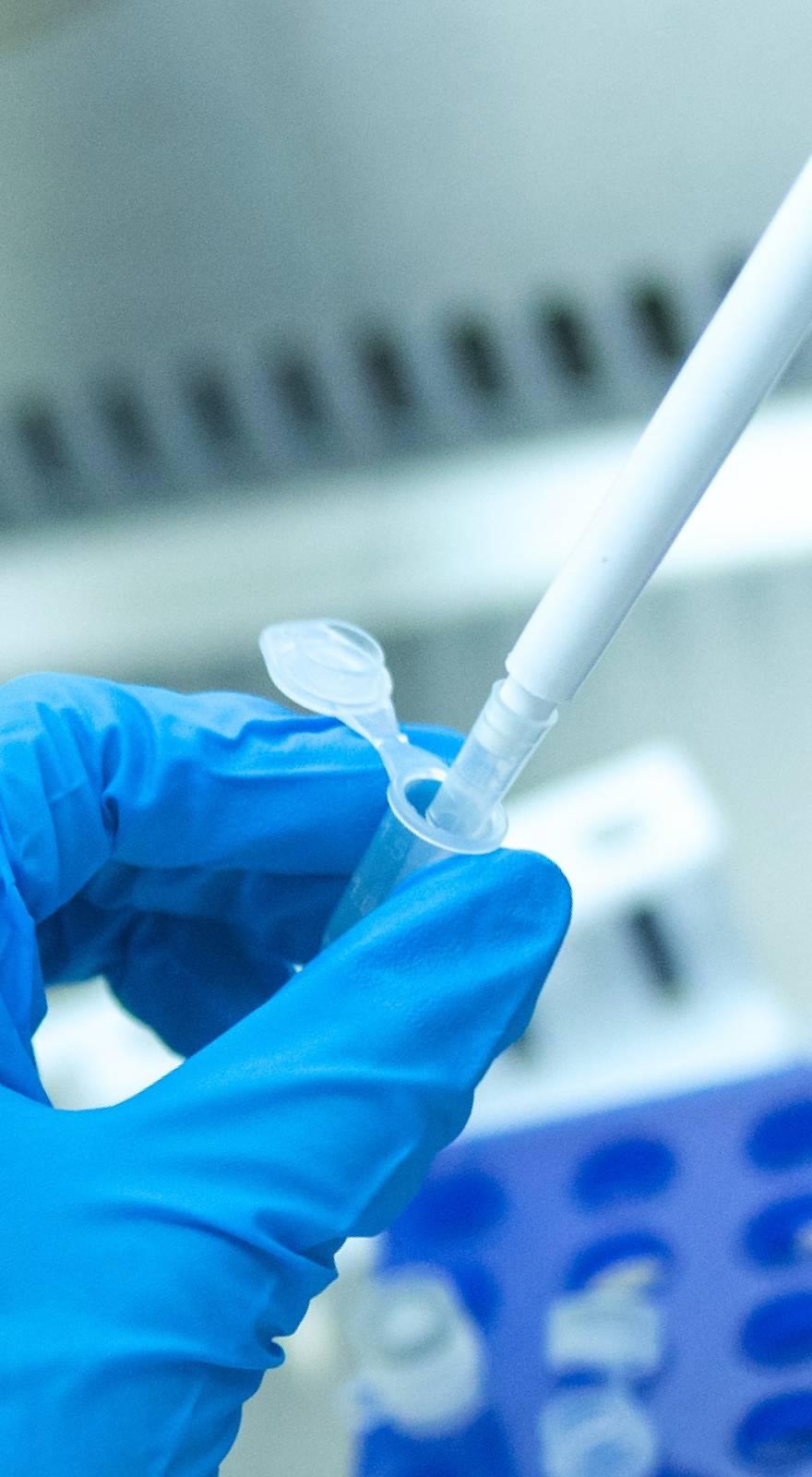

Chemiton® XT compounds are successfully used in different areas: medical technology, construction, electrical applications, home & design and automotive.

Indeed, the wide range available makes it possible to cover all the inquiries in terms of applications, from the traditional ones to the most challenging and innovative ones like multi-layer tubes (also for fatty food contact), tubes for peristaltic pumps, profiles (also with magnet), sealing, profiles for typographic applications, very thin co-extruded parts for tubes and bars (i.e. brooms).

Particularly grades for co-extrusion with adhesion onto styrenics, onto common polyamides and polyolefins are available.

Available grades

- Grades for high performance, high temperatures

- Transparent grades

- Wide range of versions (i.e. with/without mold release agent, extra UV protection, etc…) to meet all the customer’s needs

- Key Features

- Based on saturated styrenic block copolymers (HSBC)

- Wide hardness and density range

- Wide service temperature range

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Main Markets

- Extruded tubes

- Multilayer coextruded tubes

- Grips for cleaning products extruded or coextruded on PP

- Sealing and gaskets for windows and glazing

- Extruded profiles

- Magnetic gaskets

- Coextruded stopper

- Profiles for typographic and lithographic applications

- Extruded sheets

- Processing

- Extrusion

- Co-extrusion with polyolefinic polymers

- Special grades for co-extrusion

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Hardness | 45 | Shore D | — |

| Hardness | 45 | Shore A | — |

| Density | 0.89 - 1.20 | g/cm³ | — |

Regulatory & Compliance

- Certifications & Compliance

- Regulation Status

- Grades suitable for food and special grades for fatty food available

- Medical grades USP Cl. VI

- Compliant with 10/2011/CE (except for fatty foods and pH <4,5 water-based foods), 1907/2006/CE REACH Annex XIV and XVII, ROHS, RAEE, WEEE, ELV, EN71/3