Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Advantages

GAR-DUR® is designed to function in corrosive and chemical environments, in extreme cold and where abrasion resistance is a desirable factor. It is durable, has a very low coefficient of friction and high impact resistance, it is much quieter than metals, and it won't absorb fluids.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Applications

GAR-DUR® machined parts are being used in mining, pulp and paper operations, refrigeration, chemical plants, material handling industries, and automotive assembly plants to name just a few.

Properties

- Physical Properties

- Mechanical Properties

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Molecular Weight | min. 4.20e+6 | g/mol | - |

| Durometer Hardness | 67 | Shore D | ASTM D 2240 |

| Density at 23°C (73°F) | 0.941 | g/cc | D 792 |

| Rockwell Hardness | 64 | Scale R | D 785 |

| Ultimate Tensile Strength at 2"/ | 6400.0 | psi | D 638 |

| Tensile Yield Strength at 2"/min | 3400.0 | psi | D 638 |

| Tensile Yield Elongation at 2"/m | 14.0 | % | D 638 |

| Elongation at Break at 2"/min. | 350.0 | % | D 638 |

| 1% Secant Modulus | 175000.0 | psi | D 7908 |

| Izod Impact at 23°C (73°F) | Non-Break | f.p.i.n. | D 256A |

| Izod Impact at -40°C | Non-Break | f.p.i.n. | D 256A |

| Deflection Temp. at 66 psi | 80.0 | °C | D 648 |

| Deflection Temp. at 264 psi | 47.0 | °C | D 648 |

| Vicat Softening Point | 136.0 | °C | D 1525B |

| Coefficient of Linear Thermal Expansion | 9.1 x 10 | in./in./F | D 696 |

| Value | Units | Test Method / Conditions | |

| Hardness | 67.0 | - | 15 seconds; ASTM D2240 |

| Tensile Strength at Break | 44.1 | MPa | 2"/min; ASTM D638 |

| Rockwell Hardness | 64 | Scale R | ASTM D785 |

| Tensile Strength, Yield | 23.4 | MPa | 2"/min; ASTM D638 |

| Elongation at Break | 350.0 | % | 2"/min; ASTM D638 |

| Elongation at Yield | 14.0 | % | ASTM D638 |

| Flexural Modulus (1% Secant) | 1210.0 | MPa | ASTM D790B |

| Coefficient of Friction (Gar-Dur to Gar-Dur) | 0.11 | - | - |

| Coefficient of Friction (To Stainless Steel) | 0.13 | - | - |

| Coefficient of Friction (To Rolled Steel) | 0.14 | - | - |

| Abrasion | 10.0 | - | Relative, where Carbon Steel is 100 and Nylon 6/6 is 24 in; Sand Slurry Test |

| Compression Set (Temperature 20°C,24 hours after removal of 282 psi compressive stress) | 0.6 | % | - |

| Compression Set (Temperature 20°C,1 minute after removal of 282 psi compressive stress) | 0.9 | % | - |

| Compression Set (Temperature 80°C,24 hours after removal of 282 psi compressive stress) | 1.1 | % | - |

| Compression Set (Temperature 80°C,1 minute after removal of 282 psi compressive stress) | 1.6 | % | - |

| Compression Set (Temperature 20°C,24 hours after removal of 1700 psi compressive stress) | 3.5 | % | - |

| Compression Set (Temperature 20°C,1 minute after removal of 1700 psi compressive stress) | 5.4 | % | - |

| Value | Units | Test Method / Conditions | |

| CTE, linear (Temperature 20°C) | 164.0 | µm/m-°C | ASTM D696 |

| Melting Point | 130 - 131 | °C | Crystalline MP |

| Deflection Temperature at 0.46 MPa (66 psi) | 80.0 | °C | ASTM D648 |

| Deflection Temperature at 1.8 MPa (264 psi) | 47.0 | °C | ASTM D648 |

| Vicat Softening Point | 136.0 | °C | ASTM D1525B |

Technical Details & Test Data

- Test Data

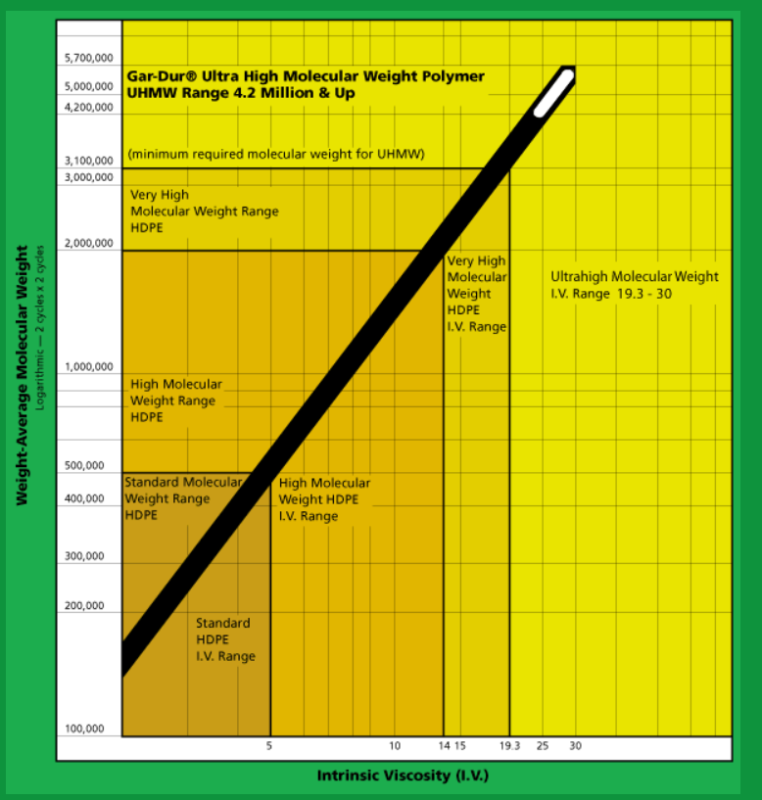

This chart shows the various molecular weights available in polyethylene. Enhanced performance characteristics are directly related to molecular weight. When comparing the abrasion resistance, the higher the molecular weight (I.V.) the greater the wear life. Gar-Dur®Gar-Dur® UHMW offers exceptional wear resistant properties.

Gar-Dur® is made from the highest molecular weight polyethylene that is consistently available. ASTM (D-4020/92) requirements for a product to be classified as true UHMW must be 3.1 million or greater.

Gar-Dur® is 4.2 million or greater.