Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

Applications & Uses

- Markets

- Applications

- Applications

- Source of acid functionality for waterborne applications.

- Co-resin to improve pigment wetting, dispersing and stabilizing.

- Pendant acid group can be used to improve adhesion in baking enamels and 2K urethanes.

- Acid groups can react with epoxy functional monomers to add acrylate functionality for UV / EB applications.

- Hydroxyl groups can be reacted with isocyanate functional acrylates to produce UV / EB cured waterborne coatings.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Hydroxyl Value | 330 - 345 | mgKOH / g | — |

| Density (25°C) | 1170 - 1200 | g/l | — |

| Acid Value | 80 - 95 | mg KOH/g | — |

| Acid Eqv | 590 - 700 | Wt., g / eqv. | — |

| Hydroxyl Eqv | 162 - 170 | Wt., g / eqv. | — |

| Color | max. 250 | APHA | — |

| Moisture | max. 0.5 | % | — |

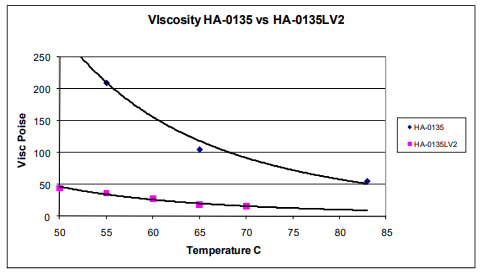

| Viscosity (25°C) | 172 | poise | — |

Storage & Handling

- Handling & Storage

Handling & Storage: DMPA® Polyol HA-0135 LV2 is very hygroscopic. Container should be sealed at all times unless discharging. Due to the reactive nature of the material, containers should be tightly sealed and stored at 0-30°C. If preheating is required for discharging, DMPA® Polyol HA-0135 LV2 should be heated to a maximum temperature of 50°C for no longer than 48 hours. If the material is exposed to >50°C for extended periods of time, undesirable side reactions may occur that could cause variations in the properties of the prepared formulations. The shelf life of the material is minimum 1 year if stored in original sealed container at 0- 30°C.