Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

- Binder Type

Epoxy Polymide

- Pigmentation

Titanium Dioxide, Aluminum Oxide, Silica

- Consistency

Thixotropic containing aggregate

Features & Benefits

Applications & Uses

- Applications

- Application Area

- Uses

Warehouse floors, parking garages, walkways, railroad cars, factory work areas, loading ramps, and any surfaces needing non-skid properties.

- Surface Preparation

As with any coating application, the better the preparation, the better the results. Prior to coating application, the surface must be clean, dry, and free of oil, grease, and other contaminants. Recommended for steel: 3 mil profile or near-white metal. The procedure to be followed in surface preparation is as follows:

- Clear the area to be cleaned of all loose equipment and rolling stock.

- Rope off an area of convenient size for cleaning and priming.

- Post "Keep Off' and "No Smoking" signs.

- For metal surfaces -

- Clean area with a Tenant Machine then with disk or drum sander.

- Remove all dust with dry oil-free compressed air.

- Coat the surface with Gryphin G-249 or G-250 Primer.

- For concrete surfaces -

- Sandblast with dry, grease-free sand.

- If sandblasting is not possible, clean with Tenant Machine followed by disk sander, drum sander and wire brushes.

- Remove all dust with dry oil-free compressed air.

- Coat the surface with Gryphin G-249 or G-250 Primer.

- Method of Application

G-2216 Epoxy Non-Skid can be applied by rolling, spraying, brushing or trowelling.

Mixing Instructions

G-2216 Epoxy Non-Skid is a two-part deck covering compound. The two parts must be thoroughly mixed before use. The following procedure is recommended:

- If G-2216 Epoxy Non-Skid has been stored in the sun, it is recommended that it be placed under cover for 24 hours before mixing. This will lower the temperature of the material and ensure the longest possible working life when mixed.

- No thinner is required for the G-2216 Epoxy Non-Skid. The consistency as received is correct for rolling, spraying, brushing or trowelling applications.

- Some settling of grit may occur in kits that have been in storage for a considerable length of time. This condition can be improved by turning cans of base material upside down 24 hours prior to mixing and by ensuring, during the mixing operation, that grit is loosened by scraping the bottom of the can.

- Add the small can of accelerator to each I gallon or 5 gallon container of base material.

- Mix thoroughly using power mixer. Scrape sides and bottom of container to ensure complete mixing. Approximately 10 to 15 minutes of mixing will be required.

Properties

- Color

- Appearance

- Textured

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Mixing Ratio (Base, Parts by Weight) | 100.0 | — | — |

| Mixing Ratio (Activator, Parts by Weight) | 5.3 | — | — |

| Specific Gravity (Mixed aint) | 1.6 | kg/l | — |

| Specific Gravity | 14.5 | lb/gal | — |

| Volume Solids | 46 - 50 | — | — |

| Drying Time (Touch) | 18 | Hours | — |

| Drying Time (Hard) | 96.0 | — | — |

| Drying Time (Re-coat) | min. 36 | Hours | — |

| Flash Point | 80.0 | ° F | Closed cup |

| Application Temperature | 50 - 90 | ° F | — |

Regulatory & Compliance

- Quality Standards

- Compliance

Meets the performance requirement of MIL-D-24483A(S) and DOD-C-24667.

Technical Details & Test Data

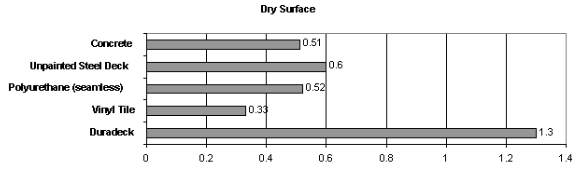

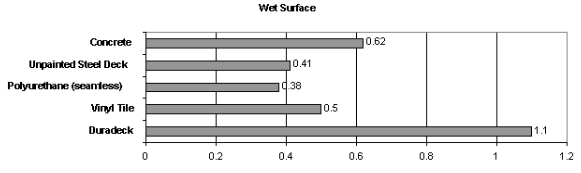

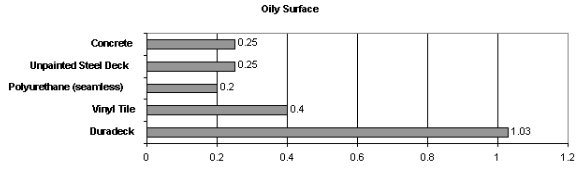

- Coefficient of Friction Characteristics

Due to its high coefficient of friction under wet or oily conditions, Duradeck provides an excellent non-skid surface for all types of flooring. The coefficient of friction values shown in the following bar graphs were obtained with an Olsen Medical Products Horizontal Pull Slipmeter, and assumes the use of rubber-soled safety shoes. Surface conditions that gave a coefficient of friction of less than 0.50 are considered slippery. The bar graphs demonstrate the vast superiority of Duradeck over other types of floor surfaces.

Figure 1: Comparative data chart between GEO-FLO™ SAFE and an ethanol solution providing the same freeze protection. The viscosity profile of GEO-FLO™ SAFE is well established and practically equivalent to alcohol based fluids which provide similar freeze protection.

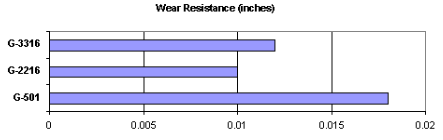

- Wear Resistance Characteristics

Wear in inches after 100 revolutions on wear test machine Wear tests conducted on a Tinius Olsen Tester greatly accelerates wear encountered under normal usage. This graph indicates the exceptional wear characteristics of each of the Duradeck formulations after 100 revolutions on the wear test machines. Least wear is encountered by G-2216 which experienced wear of only .010" after being subjected to the accelerated test. G-501 has sufficient wear resistance to give excellent service for most applications.

Storage & Handling

- Shelf Life

- 1 year (20°C)

- Storage

Storage at 68° F, Store in cool dry conditions.

Pot Life : 4 hours (20°C)