Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Cure Method

- Directions for Use

- For best performance bond surfaces should be clean and free from grease.

- To ensure a fast and reliable cure, Activator 56 or 59 should be applied to one of the bond surfaces and the adhesive to the other surface. Parts should be assembled within 15 minutes.

- The recommended bond-line gap is 0.1mm. Where bond gaps are large (up to a maximum of 0.5 mm), or faster cure speed is required, Activator 56 or 59 should be applied to both surfaces. Parts should be assembled immediately (within 1 minute).

- Excess adhesive can be wiped away with organic solvent.

- Bond should be held clamped until adhesive has fixtured.

- Product should be allowed to develop full strength before subjecting to any service loads (typically 24 to 72 hours after assembly, depending on bond gap, materials and ambient conditions).

Properties

- Physical Form

- Typical Curing Performance

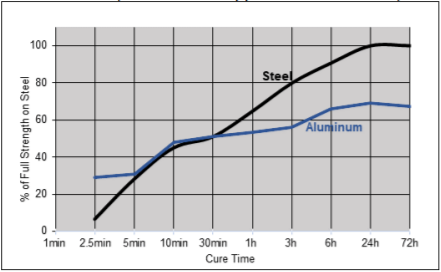

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The graph below shows the shear strength developed with time on grit blasted lap shears and tested according to ASTM D1002. (Activator 59 applied to one surface).

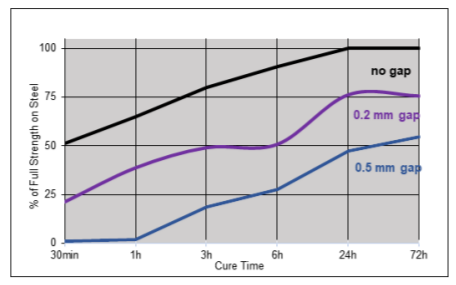

Cure Speed vs. Bond Gap

The rate of cure will depend on the bond line gap. The following graph shows shear strength developed with time on grit blasted steel lap shears at different controlled gaps and tested according to ASTM D1002. (Activator 59 applied to one surface)

- Typical Cured Performance

Cured 24 hours at 22ºC. Grit blasted steel specimens. (EF Activator 59 applied to one surface)

Test Method Property Value (psi) ASTM D1002 Shear Strength 2500-3500 - Typical Environmental Resistance

Cured for 1 week @ 22ºC, Grit blasted steel lap-shear specimens (Activator 59 applied to one surface),

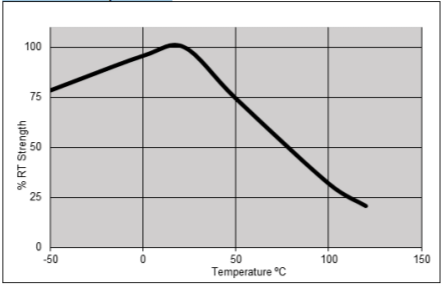

Shear Strength according to ASTM D1002.Hot Strength

Tested at temperature

Heat Aging

Aged at the temperature indicated and tested at 22°C

Aging Period Temperature Value N/mm² (psi) 1000 hours 100°C ≥17.3 (2,500) 1000 hours 120°C ≥13.8 (2,000) Chemical/Solvent Resistance

Aged under conditions indicated and tested at 22ºC.

Chemical/Solvent Temperature (ºC) % of Initial Strength (720 Hours)

Water Glycol 50/50 87 66.2 Acetone 22 14.8 Gasoline 22 75.7 Motor Oil 87 ≥100

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- General Information

This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials. For safe handling information on this product, consult the Safety Data Sheet (SDS). Where aqueous washing systems are used to clean the surfaces before bonding, it is important to check for compatibility of the washing solution with the adhesive. In some case, these aqueous washes can affect the cue and performance of the adhesive.

Storage & Handling

- Storage

ReAct® 730 should be stored in a cool, dry location in unopened containers at a temperature between 45ºF to 85ºF (7ºC to 29ºC) unless otherwise labeled. Optimal storage is at the lower half of this temperature range. To prevent contamination of unused material, do not return any material to its original container.