Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Features

- Monocomponent system

- High glass transition temperature (285°C)

- Excellent elevated temperature properties

- Easy to process

- Free standing postcure

- Short, simple cure cycles

Applications & Uses

- Markets

- Composites Processing Methods

- HexFlow® RTM651 Injection Conditions

- Preheat resin to 110°C

- Preheat mold to 150°C

- Heated transfer lines should be used, 110°C recommended

- Inject the resin into the mold at 2-3 bars (minimum)

Cure Cycle

4 hours at 191°C, 5.86 bars optimal, 3.10 bars minimumPostcure Cycle

- A postcure is required to achieve the glass transition temperature and at-temperature properties shown in chart.

- Typical postcure of 16 hours at 232°C or 6-8 hours at 245°C, free standing.

- Ramp temperature from ambient to 191'°C at a rate of 3-6°C/minute and at a rate of 0.6-1.2°C/minute above 191°C.

Properties

- Mechanical Properties

- Neat Resin Properties

- Pot Life

Temperature (°C) Viscosity 0 Hour 1 Hour 110 80 mPas 120 mPas 120 50 mPas 67 mPas Minimum viscosity 15 mPas at 156°C

- Laminate Mechanical Properties

|RTM651/3K 193 gsm PW STD MOD Carbon Test Coupon Conditioning Test Temp (°C) UOM Results Tension 0° Dry 23 Strength MPa 782 Modulus GPa 62.3 Open Hole Tension "/ 14 days H20 70°C 175 Strength MPa 291 14 days H20 70°C 190 Strength MPa 298 70°C 85%RH sat 175 Strength MPa 286 70°C 85%RH sat 190 Strength MPa 288 In Plane Shear* Dry 23 Strength MPa 87.3 175 Modulus GPa 4.89 14 days H20 70°C 175 Strength MPa 65 Modulus GPa 2.96 70°C 859%6RH sat 175 Strength MPa 65 Modulus msi 3.23 ILSS Dry 23 Strength MPa 58.1 14 days H0 70°C 175 Strength MPa 33.2 70°C 85 %RH sat 175 Strength MPa 37.5 Laminates were cured and postoured per recommended cure cycle.

*Nominal cured ply thickness 0.21 mm

**Width=36 mm

Note: Fibro used-Tonax HTA 3K- Gel Time

Temperature (°C) 150 160 177 200 Gel Time (min) 98 62 23 5 Gel time measured on a hot plate.

| Value | Units | Test Method / Conditions | |

| Tensile Strength Room Temp. (Dry) | 72.4 | MPa | - |

| Tensile Modulus Room Temp. (Dry) | 4.08 | GPa | - |

| Tensile Starin Room Temp. (Dry) | 21.9 | % | - |

| Flexural Strength Room Temp. (Dry) | 141 | MPa | - |

| Flexural Modulus Room Temp. (Dry) | 4.22 | GPa | - |

| Flexural Strength 177 (Dry) | 109 | MPa | - |

| Flexural Modulus 177 (Dry) | 31.4 | GPa | - |

| Value | Units | Test Method / Conditions | |

| Specific gravity | 1.25 | - | - |

| Tg (Dry) | 285 | °C | - |

| Tg (Wet) | 219 | °C | - |

| Fracture Toughness, K1C | 1.05 | Mpa | - |

Technical Details & Test Data

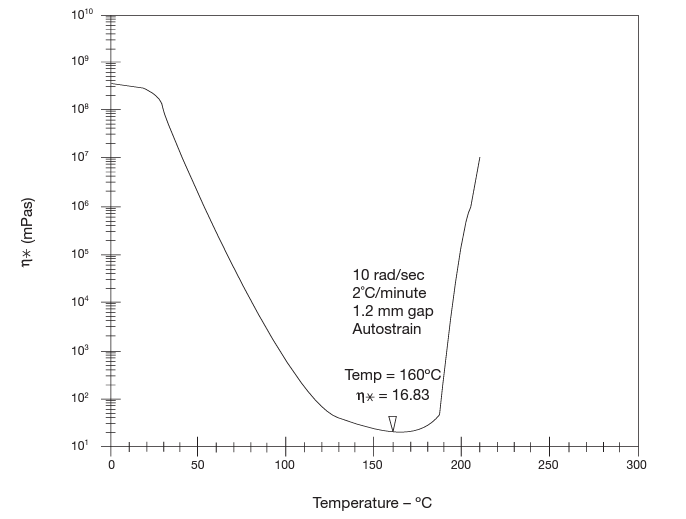

- Viscosity Profiles

Dynamic Viscosity Analysis

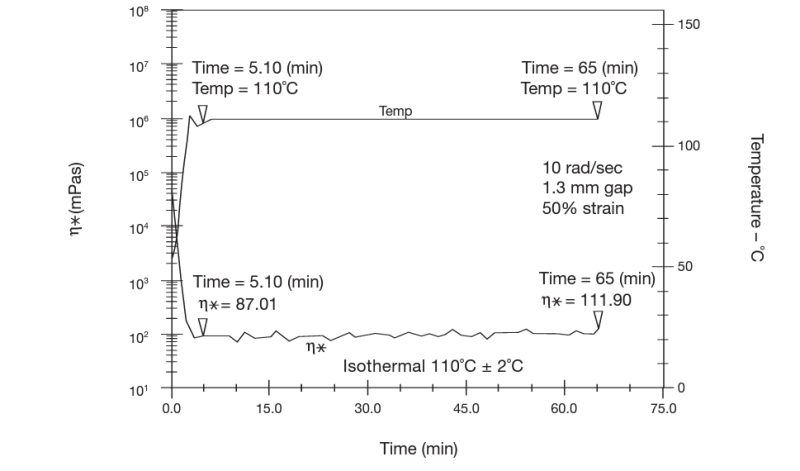

Isothermal Viscosity Analysis -110°C

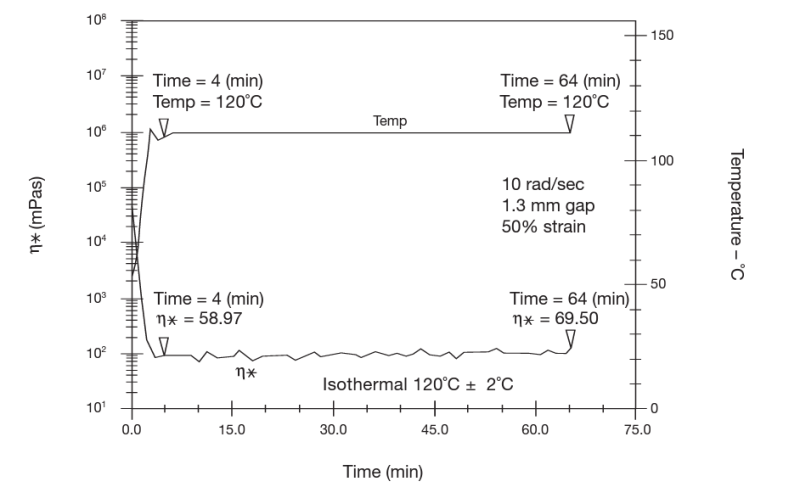

Isothermal Viscosity Analysis -110°C Isothermal Viscosity Analysis 120°C

Isothermal Viscosity Analysis 120°C

Storage & Handling

- Shelf Life

- 1 Year ( -18°C)