Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- Insures low maintenance costs to substrate.

- Provides an automotive equivalent finish.

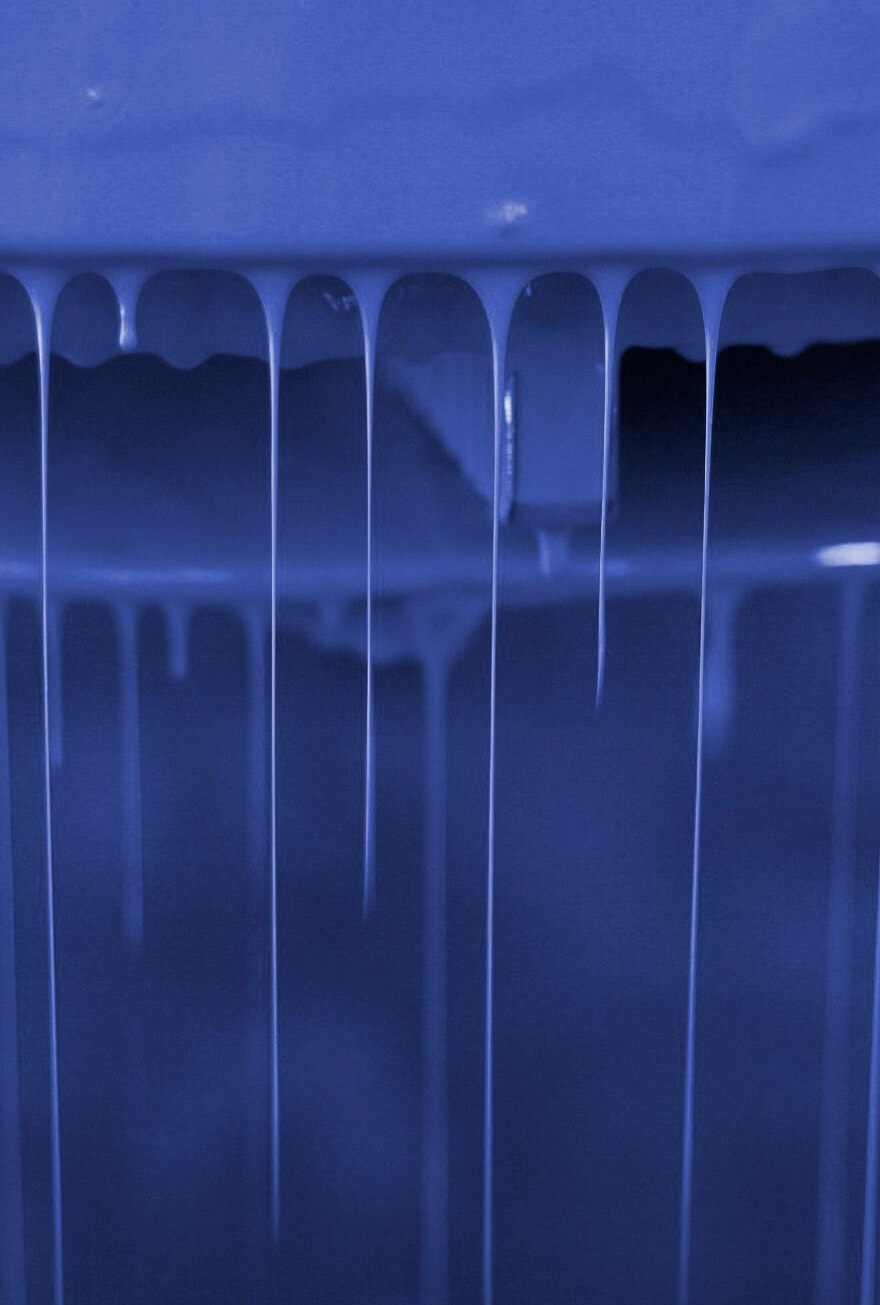

- Enhances product image with a “wet look”.

- Extends service life between product refinishing.

- Permits early handling of freshly coated surfaces because of good initial tack-free and tape times.

- Highly flexible, stain, chemical and graffiti resistant.

- Product Highlights

Life-Kote is our Super Compliant Industrial Line. This series contains a complete offering of coatings designed for use on waste handling equipment, trailer components, structural steel, utility & power equipment, heavy machinery, propane tanks, automotive parts and by manufacturers using our pharmaceutical approach to innovative coating solutions. The Life-Kote system was developed as a result of tighter environmental VOC & HAPS regulations. Each coating is formulated to extend the life cycle of equipment, parts or machinery in the field while meeting cost, performance and application requirements.

Applications & Uses

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Recommended Uses

Applications include oilfield equipment, railcars, busses, trucks, heavy off-road equipment, farm machinery, storage tanks, tractor-trailers, horse trailers, business machines, furniture, plastics, and specialty industrial applications where a long lasting, high performance coating is required.

- Application

Surface Preparation - All substrates must be cleaned free of dust, dirt, oil (including form oils and parting compounds), grease, soap residue, wax, and flaking paint. Solvent wipe and/or detergent clean surface with.

- Steel: Sandblast: (SSPC-SP-6-63), Power Tool Clean (SSPC-SP-3) or wire brush (SSPC-SP-2) steel surfaces and prime with 98 Series Epoxy Primer or 92 Series Alkyd Primer. On chemically treated steel, no primer is required for interior application. Concrete: Sandblast or acid etch with muriatic acid solution. Allow to dry before applying a thinned down primer coat. A moisture barrier should be in place to prevent water seepage.

- Plastic: The plastic should be free of mold release, grease, dirt, and dust. If necessary, wash with TZ Paint Prep. Each user should check for adhesion to each type of plastic being used. Application: May be applied by conventional, airless, air-assist airless, electrostatic, or HVLP spray only. Apply a light “tack coat”, let dry for 5-10 minutes, and then apply wet coats until desires film thickness.

- Airless: Recommended tip size is .011 to .015 orifice at 1500 to 1800 psi with 100 mesh filters. Air Spray: Use industrial equipment such as a Graco 800 G-Gun with a .070 orifice fluid tip and a #04 air cap. The atomizing pressure should be 50-60 PSI with a pot pressure of 8 to 18 PSI.

- Air Assisted: Use .011 to .015 orifice at 300 to 500 PSI fluid and 10-20 PSI air pressure.

- HVLP: Use a Graco/Croix Turbine Spray System with a .0551 gun tip or use a Graco HVLP Gun with a .055 tip. Contact you’re his Coatings Consultant for information on electrostatic spray.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Weight Gallon (mixed) | 11.11 - 11.51 | lb/gal | — |

| Volatile Organic Compounds (mixed) | 2.96 | lb/gal | — |

| Viscosity (at 77°F) | 55 - 60 | KU | — |

| Flash Point | 52 | °F | — |

| Volume Solids (mixed) | 58.67 - 62.67 | % | — |

| Weight Solids (mixed) | 71.8 - 75.8 | % | — |

| Grind | #7 | — | — |

| HMIS/NFPA | 2,3,0 | — | — |

| Mix Ratio (Parts base to part 8002 volume) | 2.5:1 | — | — |

| Thinning and Cleanup | MAK, butyl acetate | — | — |

| Vehicle Type | Polyester Urethane | — | — |

Safety & Health

- Environmental & Safety Statement

This product is not formulated with any lead, chrome or mercury containing ingredients. CAUTION! Keep away from heat and open flame. Avoid prolonged contact with skin and breathing of vapor or spray mist. Do not take internally. Close container after each use. Use only with adequate ventilation. Use respiratory devices and other personal protective equipment required by OSHA 29CFT 1910. KEEP OUT OF REACH OF CHILDREN.