Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Benefits

- Excellent Gloss & Color Retention

- Excellent Sag Resistance

- Excellent Adhesion

- Excellent Recoat

- Excellent Corrosion Resistance

- Excellent Hardness

- VOC Compliant/ Low HAPS/SARA 313

- Product Highlights

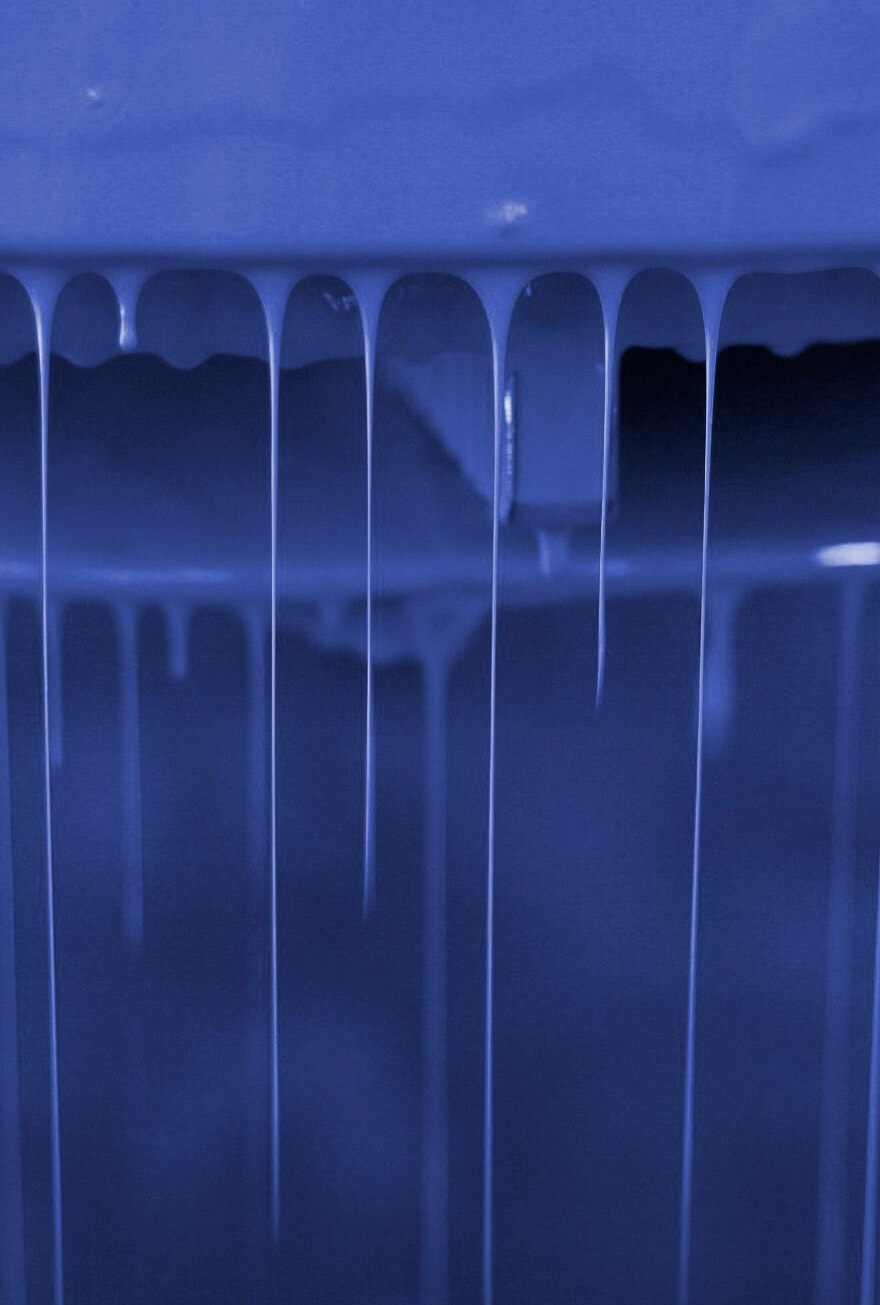

Life-Kote is our Super Compliant Industrial Line. This series contains a complete offering of coatings designed for use on waste handling equipment, trailer components, structural steel, utility & power equipment, heavy machinery, propane tanks, automotive parts and by manufacturers using our pharmaceutical approach to innovative coating solutions. The Life-Kote system was developed as a result of tighter environmental VOC & HAPS regulations. Each coating is formulated to extend the life cycle of equipment, parts or machinery in the field while meeting cost, performance and application requirements.

Applications & Uses

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Recommended Uses

Applications include OEM horse trailer, offroad construction equipment, farm machinery, livestock equipment, waste containers, storage tanks, tractor trailers & industrial finishing where both high performance and fast production on the paint line are required.

- Surface Preparation

All substrates must be cleaned free of dust, dirt, oil (including form oils & parting compounds), grease, soap residue, wax and flaking paint. Solvent wipe and/or detergent clean surface in accordance with SSPC-SP1. Sandblast or wire-brush rusty surfaces and prime with 92 Series Alkyd Primers. For optimum adhesion and corrosion resistance, metal should be iron or zinc phosphate treated.

- Application

May be applied by air, airless, air-assisted airless, turbo or HVLP spray. Product may also be applied by dip or flowcoat. For thinning instructions, contact your local H-I-S sales representative. Recommended tip size for airless or air assisted airless spray: .011” to .015” orifice. For peak performance, 8000 or 8002 urethane converter may be added at a rate of 1 part converter to 8 parts paint by volume.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Coverage (at 1 Dry Mil) | 707.27 | sq.ft./gal | — |

| Volatile Organic Compounds (Coating) | 3.07 | lb/gal | — |

| Volatile Organic Compounds (Material) | 3.47 | lb/gal | — |

| Weight Gallon | 9.73 | lb/gal | — |

| Viscosity (at 77°F) | 25 - 30 | Inch | #2 Zahn |

| Force Cure Temperature | 150 - 300 | °F | — |

| Volume Solids | 42.1 - 46.1 | % | — |

| Weight Solids | 58.58 - 62.58 | % | — |

| Grind | #7 | — | Hegman |

| Gloss (at 60°) | 87 - 97 | — | — |

| Vehicle Type | Acrylic Modified Alkyd | — | — |

| Drying Time | Air Dry or Force Cure | — | — |

| Reduction and Cleanup | MAK, Solvent 100 | — | — |