Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- High Solids Protective Finish

- Chemical Resistant

- Abrasion Resistant

- Stain Resistant

- Washable

- Excellent Flexibility

- Excellent Durability

- Product Highlights

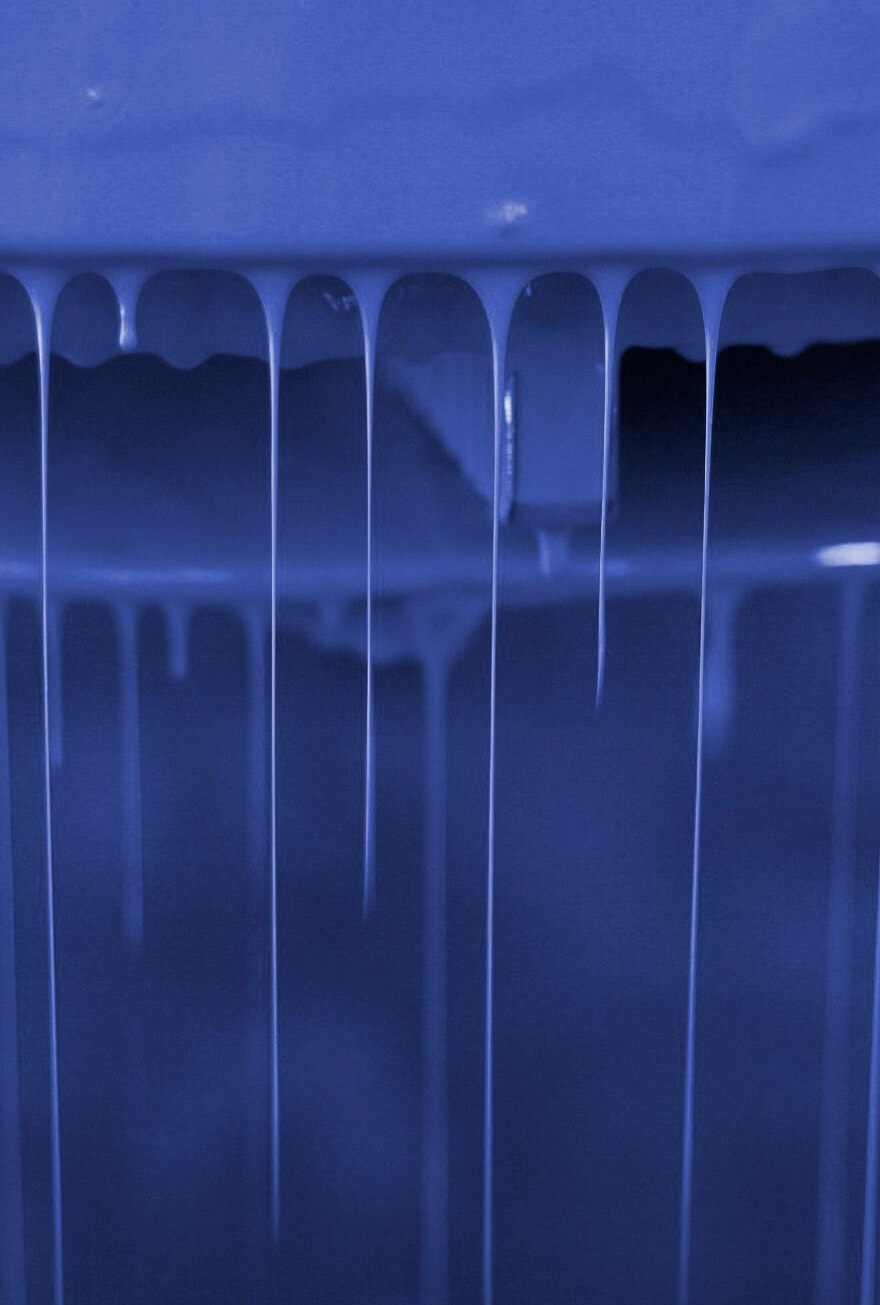

- Life-Kote is our Super Compliant Industrial Line. This series contains a complete offering of coatings designed for use on waste handling equipment, trailer components, structural steel, utility & power equipment, heavy machinery, propane tanks, automotive parts and by manufacturers using our pharmaceutical approach to innovative coating solutions.

- The Life-Kote system was developed as a result of tighter environmental VOC & HAPS regulations. Each coating is formulated to extend the life cycle of equipment, parts or machinery in the field while meeting cost, performance and application requirements.

Applications & Uses

- Applications

- Application Area

- Application Method

- Cure Method

- Recommended Uses

Substrates include both interior and exterior applications on a variety of metal substrates such as OEM farm machinery,

- Surface Preparation

- All substrates must be cleaned free of dust, dirt, oil (including form oils & parting compounds), grease, soap residue, wax, flaking paint, and any other contaminants.

- All burrs should be removed and sham edges or rough weld seams should be ground down. The substrate should be thoroughly degreased in accordance with SSPC-SPI.

- Solvent wipe and/or detergent clean surfaces before application. Sandblast or wire-brush surfaces to remove rust and mill scale.

- For optimum adhesion and corrosion resistance, hot roll steel should be iron or zinc phosphate treated after mechanical grit blast removal of mil scale.

- Application

Mix 1 part epoxy activator to 4 part epoxy base. Recommended tip size for air-assist or airless spray: 0.013” to 0.017” orifice. Primer does not require a topcoat. However, Must be topcoated within 1 week or scuff sanding will be required due to surface hardness. Stripe coat all crevices, welds and sharp angles to prevent early failure in these areas.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Coverage (at 1 Dry Mil) | 830 | sq.ft./gal | — |

| Drying Time (at 70°F and 50% RH, To Touch) | 20 | Minutes | — |

| Drying Time (at 70°F and 50% RH, To Recoat) | 30 | Minutes | — |

| Induction | min. 1 | Minutes | — |

| Recommended Coverage (Dry Film Thickness) | 2 - 4 | mils | — |

| Coverage (Deposits at 400 Sq.ft/gal Spread Rate, Dry) | 2.2 | mils | — |

| Weight Gallon (mixed) | 11.65 - 12.05 | lb/gal | — |

| Volatile Organic Compounds (mixed) | 3.31 | lb/gal | — |

| Viscosity (Base) | 60 - 70 | KU | — |

| Viscosity (Catalyst) | 17 | Inch | #2 Zahn |

| Pot Life | max. 16 | Hours | — |

| Volatile Organic Compounds | 396 | g/l | — |

| Drying Time (at 70°F and 50% RH, Full Cure) | 7 | Days | — |

| Maximum Recoat (at 75°F, Or scuff sand is required) | 7 | Days | — |

| Flash Point | 47 | °F | TCC |

| Volume Solids (mixed) | 49.8 - 53.8 | % | — |

| Weight Solids (mixed) | 68.4 - 72.4 | % | — |

| Grind | #6 | — | — |

| HMIS/NFPA | 3,3,0 | — | — |

| Gloss (at 60°) | 30 - 40 | — | — |

| Thinning and Cleanup | Epoxy Thinner | — | — |

| Vehicle Type | Epoxy/Polyamide | — | — |

| Federal Specifications | TT-C-535 | — | — |

Safety & Health

- Environmental & Safety Statement

This product is not formulated with any lead, chrome or mercury containing ingredients. The maximum VOC does not exceed 450 g/l. Do not take internally. Keep out of the reach of children. Use with adequate ventilation.