Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Applications

- Applications

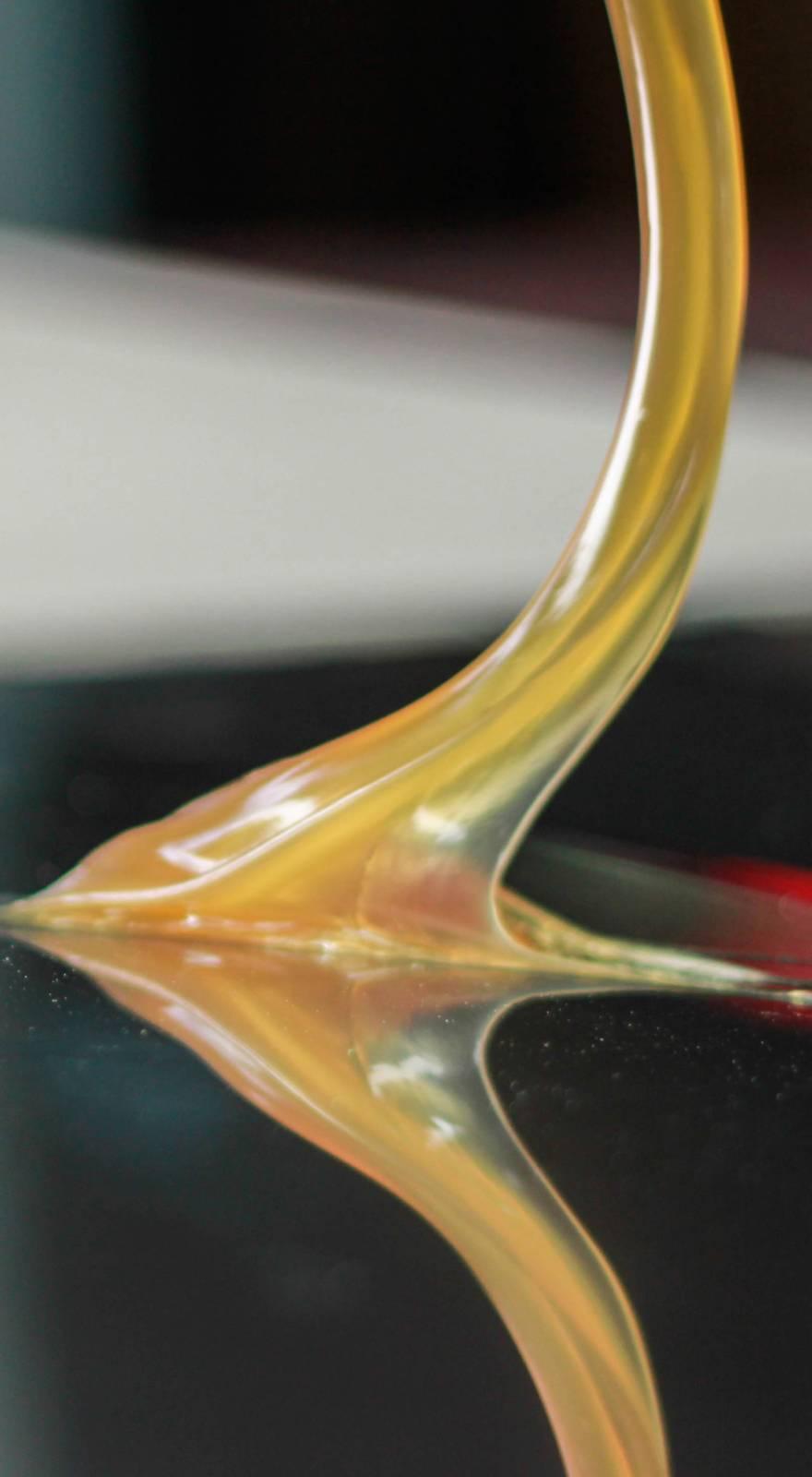

This formula is specially designed for a wide spectrum protection either of hot-melt polymer systems or of polymer solutions. It can be used with adhesives, pressure sensitive adhesives, coatings, injection molding or extrusions.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Total Solids | 99±1 | % | — |

Packaging & Availability

- Packaging Type

- Packaging and Storing

Packaging

ANTIOX AHM-EC2 PELLETS is normally supplied in 40-50 kg fiber drums.

Storing

ANTIOX AHM-EC2 PELLETS must be stored in a dry place to avoid agglomeration. Shelf life is 1 year.

Storage & Handling

- Shelf Life

- 24 Months

- Handling

For HOT-MELT adhesives ANTIOX AHM-EC2 PELLETS is very efficient at the following concentrations :

- Thermoplastic rubbers, like SIS, SBS (e.g. Cariflex, Solprene, etc.): 1.2-1.5% on rubber content.

- Ethylene-vinylacetate (EVA, type ELVAX, etc.): 0.3-0.5% on EVA content.

- Thermoplastic polyurethanes (e.g. ESTANE, DESMOCOLL, etc.): 0.2-0.4% on PU content.

- Polyamides (e.g. Reammide, Versamide, etc.): 0.5-1.0% on PA content.

For SOLVENT BASED adhesives ANTIOX AHM-EC PELLETS is very efficient at the following concentrations :

- Natural rubber, SBR, chloroprene rubber, polyisoprene, butyl rubber: 0.25-0.5% on dry content.

ANTIOX AHM-EC2 PELLETS can be introduced directly into the compound, together with other recipe ingredients, or predispersed into one of them or dissolved (if it is a matter of solvent). In the hot-melt continuos system (by extrusion process) it is advisable that a liquid component (like liquid rosin esters or naphtalic oil, etc.) is used to give some tack to the surface of granules, in order to have a fair distribution over the total mass. In the solvent systems, one can make a solution concentrate (hexane, toluene, etc.), for example at 5 - 10% of solids.