Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Cure Method

- Coating Type

- Applications

It cross-links polymers/elastomers used as coatings, adhesives, primers, paints, etc, increasing strength, cohesion, adhesion to substrates and chemical/physical resistance.

Properties

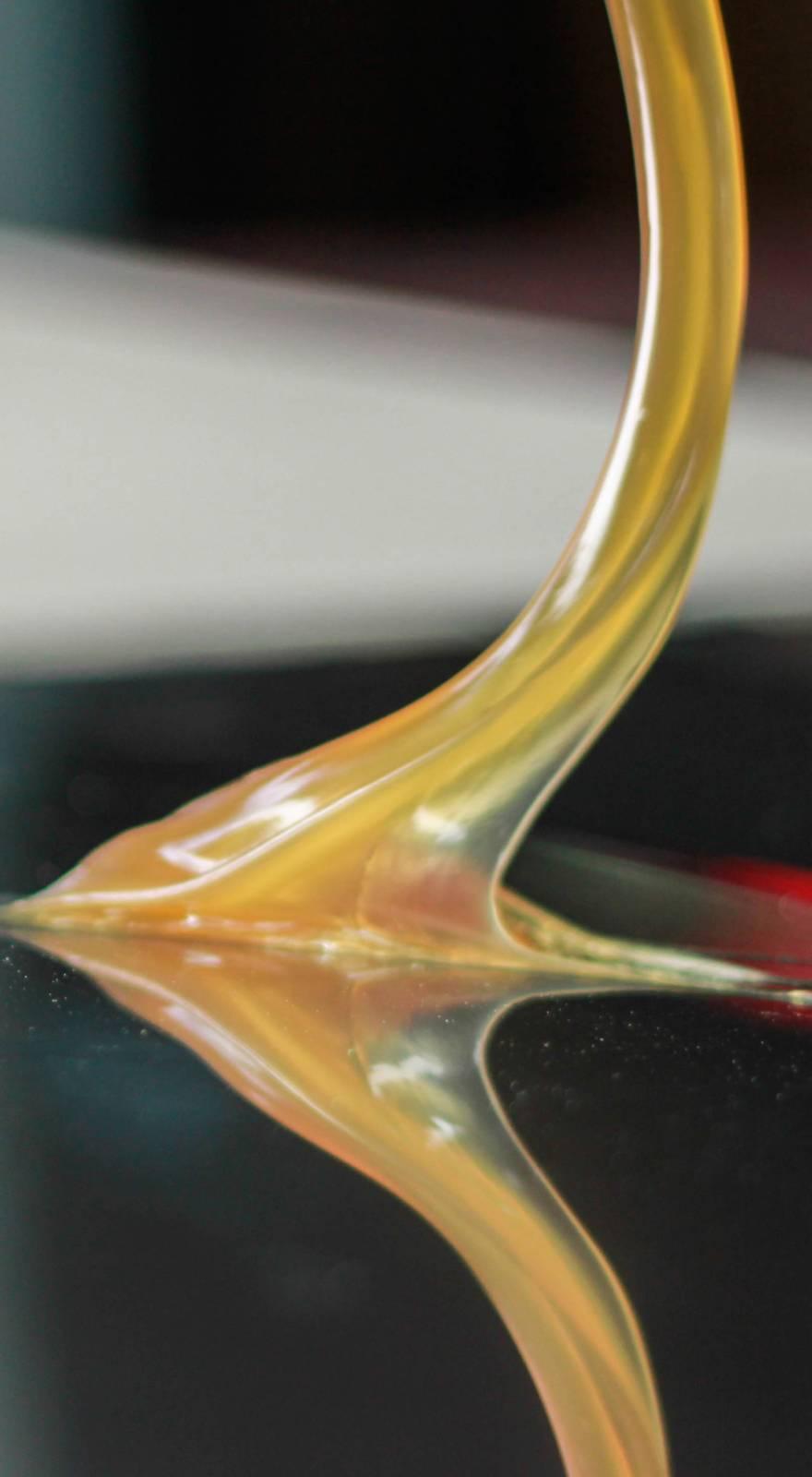

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Total Solids | 65±1 | % | — |

| Solvents | toluene | — | — |

| NCO Content | 19 - 211 | % | — |

Packaging & Availability

- Packaging and Storing

Packaging

The product is supplied in iron drums (10 kg); plastic drum (25 kg); iron drums (60 kg).

Storing

Polyisocyanates react with water, including atmospheric moisture, with formation of carbon dioxide, which can cause too high pressures in closed containers and form solid insoluble polyureas, which can block pipes, valves, etc. Product must be stored in well sealed original containers, far from any fire sources, at temperatures between 0°C and 30°C. At higher temperatures it can develop hazardous vapors. Opened drums must be protected from moisture penetration (use silica gel drying tube or nitrogen atmosphere systems). Use within 6 months from production date (unopened and in the original packaging).

Storage & Handling

- Shelf Life

- 6 Months

- Handling

In solvent borne primers: add 4.5 -14 % of CURING AGENT D referred to total solids.

In natural rubber (as our TACKSOL series) or acrylic solvent borne adhesives: add 1.5-4.5% of CURING AGENT D on the total solids of the adhesive.Add CURING AGENT D to polymer/solution and properly stir to complete dissolution.

Reaction starts immediately, thus we recommend using the product immediately after the activation. The crosslinking mechanism depends upon different parameters, such as adhesive concentration, amount of crosslinker, temperature. We suggest checking the curing conditions in advance, in order to avoid spoiling material.