Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Adhesive & Sealant Type

- Applications

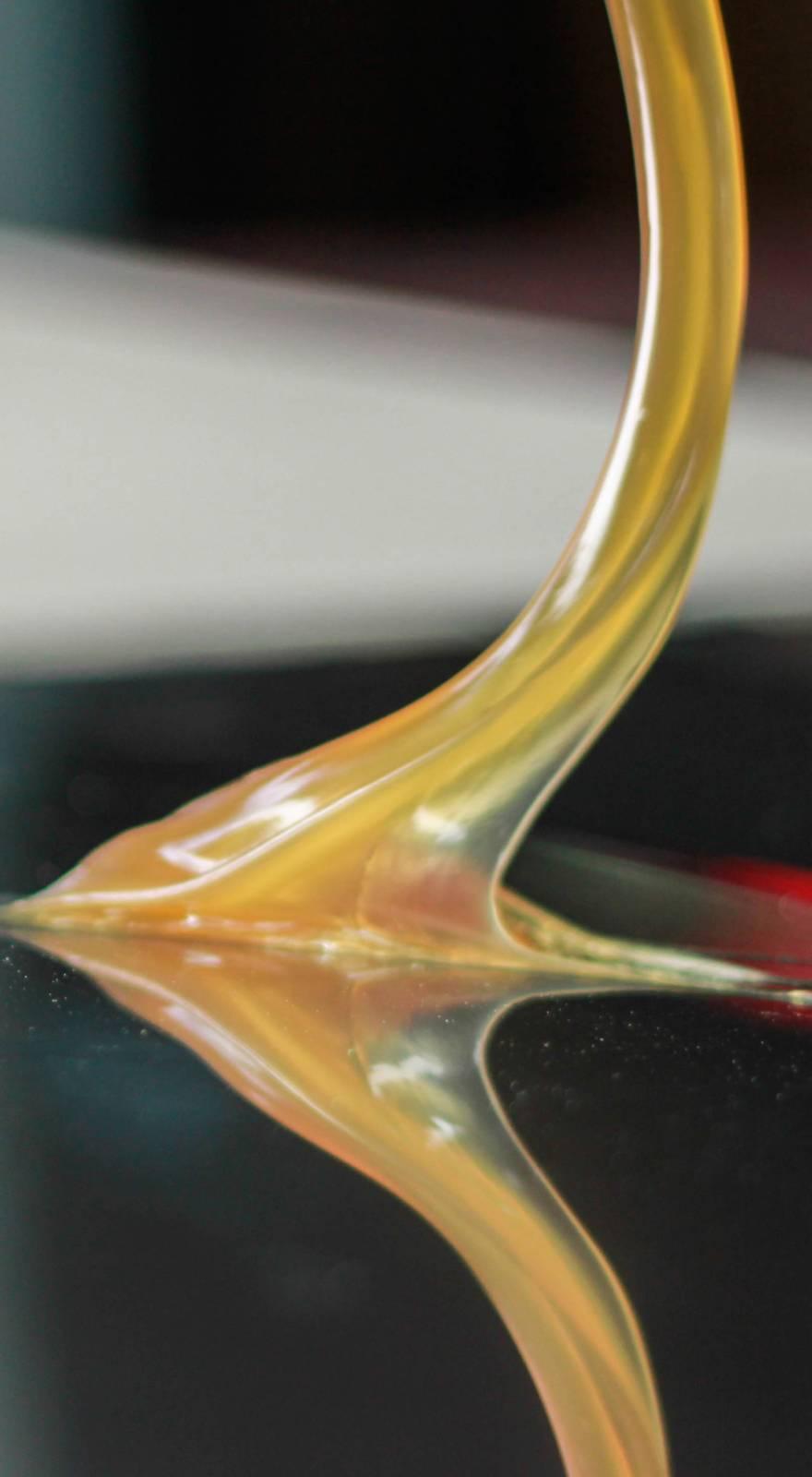

The product is designed to be used as a very efficient release agent for adhesive tapes in polypropylene, polyethylene, PVC, reinforced PVC, polyester. It can be used with solvent rubber, hot-melt and acrylic adhesives. The product has been developed to have a higher unwinding force in comparison to our reference product RELEASE K 100 D.

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Solvents | toluene | — | — |

| Total Solids | 20±0.50 | % | — |

Storage & Handling

- Handling

Before taking any quantity from the original drum,

RELEASE K 20 DL should be heated at about +40°/+50°C and stirred till fluidity and transparency are completely restored. The products tends to become a gel at temperatures below +30°C.

Also its diluted solutions tend to jellify and should be heated over +30°C and stirred till the final coating on the films. Dilute with toluene at a concentration between 0.2 and 2% max, depending on coating method and on the desired result. Coat 3-5 g (wet)/m² with gravure cylinder or mayer bar, dry it perfectly before winding the adhesive tape.- Storing

The product must be stored at temperatures higher than +18°C. Keep away from direct sunlight. Keep containers tightly closed to prevent solvent evaporation.