Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Product Highlights

Javachem® HG enriching on the surface imparts PP interior material with excellent and long-lasting scratch resistance without stickiness and yellowing after exposure to light at high temperature. It can also effectively avoid stress whitening problem that normally exists when scratch resistant agent is added. Due to its own characteristics, it can improve the interior air quality of automotive from the source, which is more eco-friendly and safer.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Application

Comparison on application features of different types of scratch resistant agents

Test item Javachem®HG Imported anti-scratch Silicone anti-scratch Product ingredient with functional group special silicone traditional silicone Anti-scratch performance +++ ++ + Anti-scratch persistence +++ ++ + Impact performance ++ + ++ Stress whitening Resistance ++ + -- Haze performance ++ ++ + Light, heat aging resistance ++ ++ + Odor, VOC performance ++ + ++ Dosage low medium high Application test

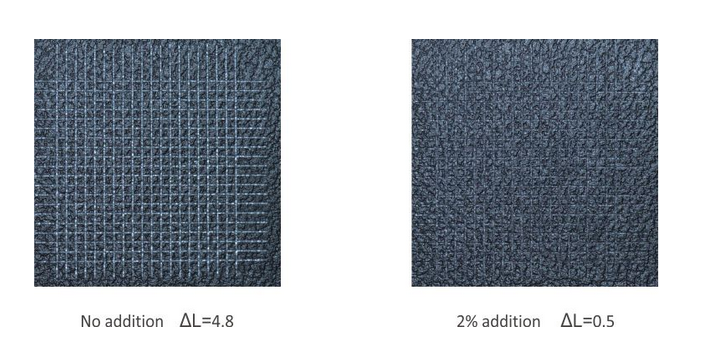

Test item Javachem®HG Imported anti-scratch Silicone anti-scratch Cross scratch ΔL (10N) 0.45 1.37 2.54 Cross scratchΔL (10N)(102℃,168h) 0.52 0.98 1.93 Stress whitening ΔL 0.20 1.03 1.45 Tensile strength (MPa) 22.58 21.68 22.07 Flexural strength (MPa) 29.59 29.32 29.68 Breaking elongation (%) 63.78 68.25 64.05 Notch impact strength (23℃,kJ/m2) 27.66 26.55 27.60 Surface migration no no no Surface migration (thermal aging 168h) no no no

Technical Details & Test Data

- Resistance

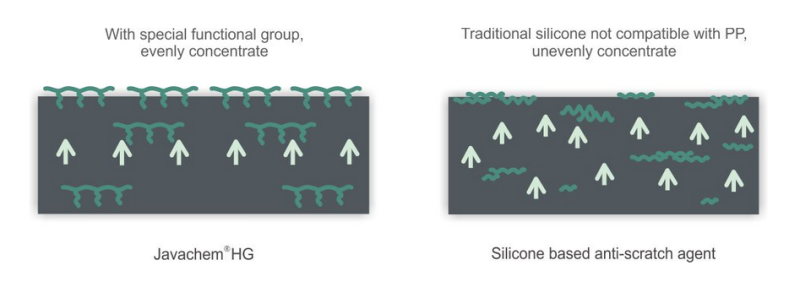

Javachem®HG acts with anchoring effect in PP resin, which can easily concentrate on the surface and impart PP interior material with excellent scratch resistance.

Scratch resistance of Javachem®HG in PP material

(PP+20%Talc, PV3952,10N)