Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- CAS No.

- 50926-11-9

- EC No.

- 610-589-1

- Technologies

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Key Features

- High transparency in the visible part of the sunlight spectrum

- Outstanding ability to absorb infrared light

- Good electrical conductivity

- High chemical stability

- Features

- Indium tin oxide (ITO) has been known for a long time for its use as a transparent conductive oxide in electronic applications. Everyone who uses a touch screen most likely has indium tin oxide under their fingertips. Indium tin oxide is a vital component of modern electronics due to its unique features.

- Indium tin oxide exists in several modifications depending on the manufacturing process, which can be identified not only by a varying composition in respect to the indium to tin ratio, but also by its color. The most chemically stable form of ITO has a yellow color, whereas the reduced form is a blue colored powder. ITO with a greenish color is a mixed form generated by high temperature processes.

- Key features of Indium Tin Oxides

- High transparency in the visible part of the sunlight spectrum

- Outstanding ability to absorb infrared light

- Good electrical conductivity

- High chemical stability

- Product Highlights

- Using a proprietary process, ITO is converted into its blue form, which significantly increases the ability of the ITO to absorb IR light without compromising the transparency in the visible range.

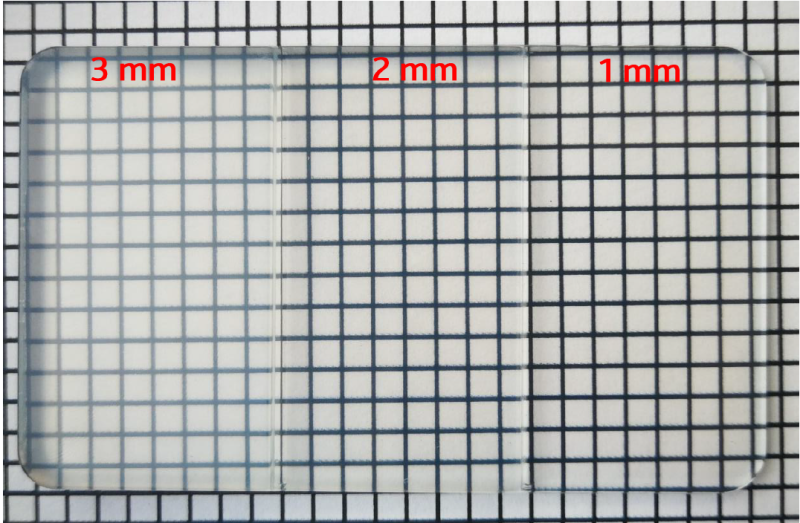

- Irasorb BITO and BITOM40 are powders which can be easily dispersed in polymers during the extrusion or injection molding process. They deagglomerate readily into nanoscale particles to enable transparent polymer films, sheets and plates to be formed.

- Although the BITO powder is of blue color it has only very little influence on the final color of polymers, coatings or inks.

- BITO has excellent IR absorbing properties, with its maximum IR absorption reached at 1100 nm. Low quantities of BITO are necessary to achieve high NIR absorption rates. In addition, BITO has the highest transparency of all IR absorbing materials.

- Keeling & Walker offers indium tin oxides in both powder form and as nanoscale dispersions in water, plasticiser and other solvents to facilitate the use of the ITO and to ease the formulation of inks and coatings.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating Type

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- IRASORB BITO, the blue Indium Tin Oxide shows higher electrical conductivity and higher absorption in infrared light compared to the yellow version, which makes it useful for coatings, inks and polymeric films.

- The main uses of these films are for heat shielding on architectural and automotive glass, where they combine high transparency and low color in the visible range with superior absorption properties in the infrared region.

Properties

- Typical Properties

- Specifications

| Value | Units | Test Method / Conditions | |

| Specific Gravity | 7.1 | — | — |

| Primary Particle Size (from BET) | max. 25 | nanometres | — |

| Value | Units | Test Method / Conditions | |

| Surface Area | min. 30 | m²/g | BET |

| Powder Resistivity | max. 0.2 | Ohm. cm | — |

| Agglomerate Size, D50% (by laser diffraction) | max. 10 | microns | — |

| Chemical Purity (trace metals basis) | min. 99.9 | % | Trace Metals Basis |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Product Information

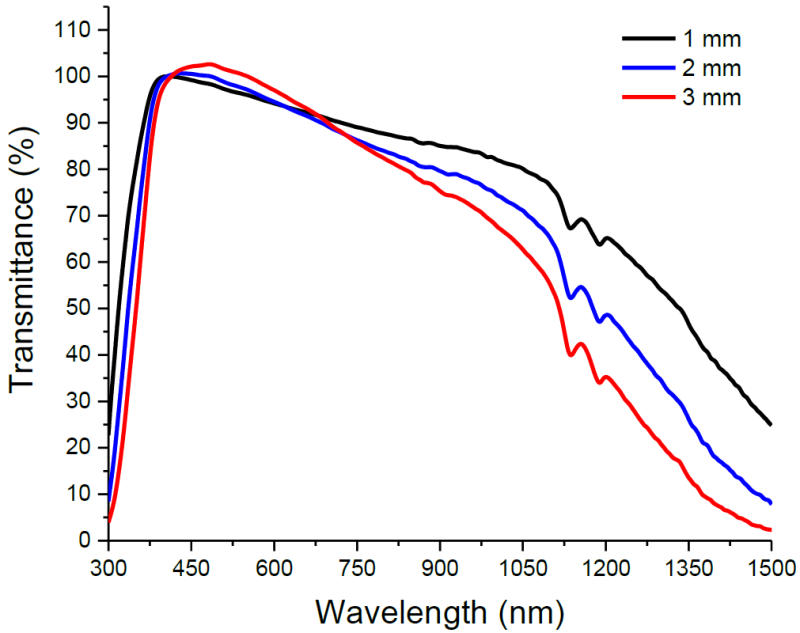

0.1 wt.% IRASORB BITO in polycarbonate @ 1, 2 and 3 mm thickness

Optical Properties

Plaque Thickness (mm) UV T (%) VL T (%) IR R (%) SHGC (%) 1 43.7 73.3 38.3 0.69 2 27.2 62.3 50.7 0.58 3 16.2 55.1 61.8 0.50 T = transmittance

R = rejection

SHGC = Solar Heat Gain Coefficient

Transmittance Curves