Knowde Enhanced TDS

Identification & Functionality

- Catalyst Type

- Chemical Family

- Reaction Phase

- CASE Ingredients Functions

- Industrial Additives Functions

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Advantages

- Excellent cure response

- Excellent exterior durability

- Does not contribute to the hydrolysis of polyester resins

- Short tack free time

- High selectivity for -NCO/OH reaction over -NCO/water reaction

- Pot life adjustable with stabilizer

Applications & Uses

- Markets

- Compatible Polymers & Resins

- Industrial Additives End Use

- Use Level

- 0.3 - 2% (on total resin solids)

- Applications

Polyurethane coatings, adhesives, RIM, casting resins and polyurethane resin synthesis, water-borne two component coatings.

- Incorporation

Addition of the catalyst to the polyisocyanate is suggested as the best method to assure catalytic activity.

Properties

- Color

- Physical Form

- Appearance

- Clear, Straw liquid

- Soluble in

- Aliphatic hydrocarbons, Aromatic hydrocarbons, Alcohols, Esters, Ketones, Glycol ethers and glycol ether acetates

- Partially Soluble in

- Water (will hydrolyze water )

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity (25°C) | 0.98 | — | — |

| % Active (Metal Chelate) | 2 | % | — |

Technical Details & Test Data

- Test Data

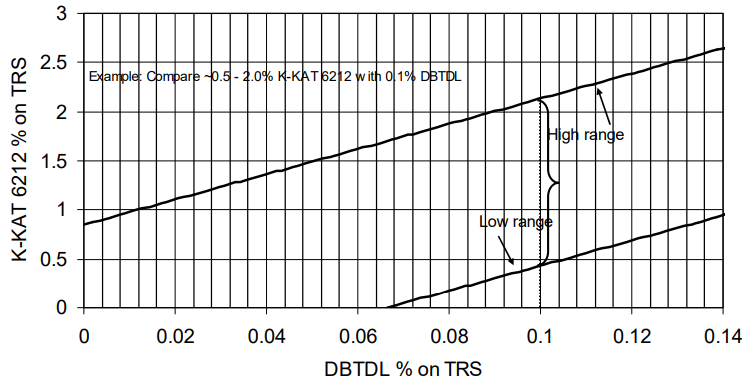

K-KAT 6212 Catalyst Concentration on TRS*

DBTDL Replacement Level

* catalyst level as supplied based on total resin solids

Storage & Handling

- Shelf Life

- 12 months

- Storage/Shelf Life

- K-KAT 6212 is sensitive to moisture.

- Exposure to atmospheric moisture during storage should be avoided.

- This product is designed to be premixed with the polyisocyanate component or to be added just before application of two component systems.

- Avoid contact with metals.

- 12 months from the date of manufacture, when stored at ambient conditions in the original container.