Knowde Enhanced TDS

Identification & Functionality

- Catalyst Type

- Reaction Phase

- Industrial Additives Functions

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Advantages

- Excellent cure response

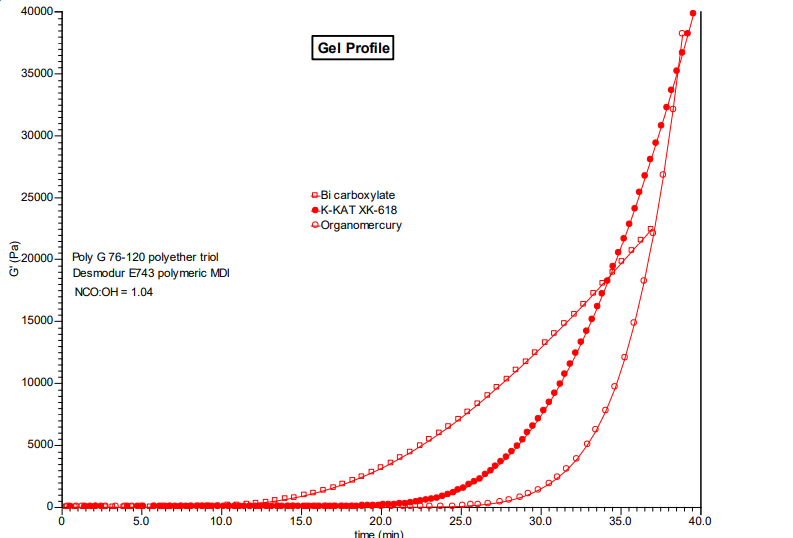

- Similar cure profile to mercury catalysts

- Environmentally more acceptable

Applications & Uses

- Compatible Polymers & Resins

- Use Level

- 0.1 - 1% (as supplied on total resin solids)

- Applications

100% solids 2K urethane elastomers. K-KAT XK-618 provides gel times and cure properties similar to mercury catalysts.

- Incorporation

K-KAT XK-618 can be added directly to the polyol component of a 2K system.

Properties

- Appearance

- Pale, Light amber liquid

- Soluble in

- Glycol ethers, Ketones, n-Butanol, Aromatic, Aliphatic hydrocarbons

- Partially Soluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| % Metal | 2.1 | % | — |

| Specific Gravity (25°C) | 1 | — | — |

| Volatile | Glycol ethers | — | — |

Technical Details & Test Data

- Test Data

Viscosity profile measured at ambient temperature

Storage & Handling

- Shelf Life

- 24 months

- Storage/Shelf Life

- Safe handling of this product should include the use of safety glasses and gloves.

- Avoid breathing vapors - use with adequate ventilation.

- Product should be stored in lined or glass containers away from sunlight and excessive heat.

- 24 months from the date of manufacture, when stored at ambient conditions in the original container.