Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Processing Notes

MOWIFLEX™ C 17 should be processed at temperatures between 190 and 210°C. The material absorbs moisture once the packaging is opened and should therefore be processed only from unopened original containers. Otherwise bubbles may occur in the product. Damp material can be dried at 60°C – 80°C for 6 – 8 hours in a circulating-air dryer. Dry content can be determined shortly before extrusion, e.g. by using an infrared moisture analyzer.

Melt temperature during extrusion should not exceed 220°C because at higher temperatures the material suffers thermal damage, recognizable by yellow discoloration and an increase in melt pressure and torque. Residence time should be held as short as possible, 5 –10 minutes at most. When extruder operation has to be stopped temporarily it is highly recommended to completely purge out MOWIFLEX™ resins from the extruder.

Material change and extruder cleaning

To remove MOWIFLEX™ from the extruder it should be purged with a polyolefin (e.g. LDPE) of similar or lower melt flow index until all MOWIFLEX™ is removed from the extruder. Depending on the extruder design and if purging is not sufficient, however, this can leave MOWIFLEX™ residues in the barrel and/or die, which can then crosslink or degrade under the influence of heat. In this case it is advisable to dismantle the extruder for cleaning. Before starting MOWIFLEX™ processing it is recommended to purge the extruder with a high melt flow index polyolefin (e.g. LDPE). Subsequently, the extruder should be purged with MOWIFLEX™ until the polyolefin is completely removed from the extruder.

Properties

- Soluble in

- Cold Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Bulk Density | 0.6 - 0.9 | g/cm3 | — |

| Methanol Content | max. 1 | wt % | — |

| Glass Transition Temperature | 60 | °C | — |

| Melt Flow Index - MFI (190°C/21.6 kg) | 14 - 20 | g/10 min | — |

| Melting Temperature | 170 | °C | — |

| Volatiles Content | max. 1 | wt % | — |

Regulatory & Compliance

- Biodegradability

MOWIFLEX™ C 17 is certified by Vinçotte as “OK biodegradable water” based on an official biodegradation test according to ISO 14851.

Technical Details & Test Data

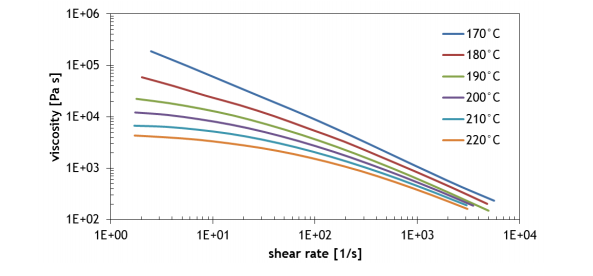

- Viscosity Curve

Storage & Handling

- Safety and Handling

MOWIFLEX™ resins are dried after production and packaged in moisture proof bags. This means that no drying is needed when the material is used from fresh bags. The bags should be stored indoors under dry conditions. Open bags should be resealed after use. When exposed to the atmosphere MOWIFLEX™ will absorb moisture, which might result in foam or bubble formation during processing. Damp material can be dried at 60-80°C for 6-8 hours in conventional circulating air dryers. To estimate the moisture content of MOWIFLEX™ the volatiles content can be measured with an infrared moisture analyzer at 105°C for 10 minutes. The result of the volatiles content measurement will not perfectly equal the moisture content, due to partial evaporation of plasticizer. Usually a volatiles content of <0.4% will be sufficient.

MOWIFLEX™ C 17 is not a dangerous substance or preparation as defined by German chemical law or dangerous goods regulations or EC regulation 1272/2008 (CLP regulation) in their current versions.