Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Applications & Uses

- Cure Method

Properties

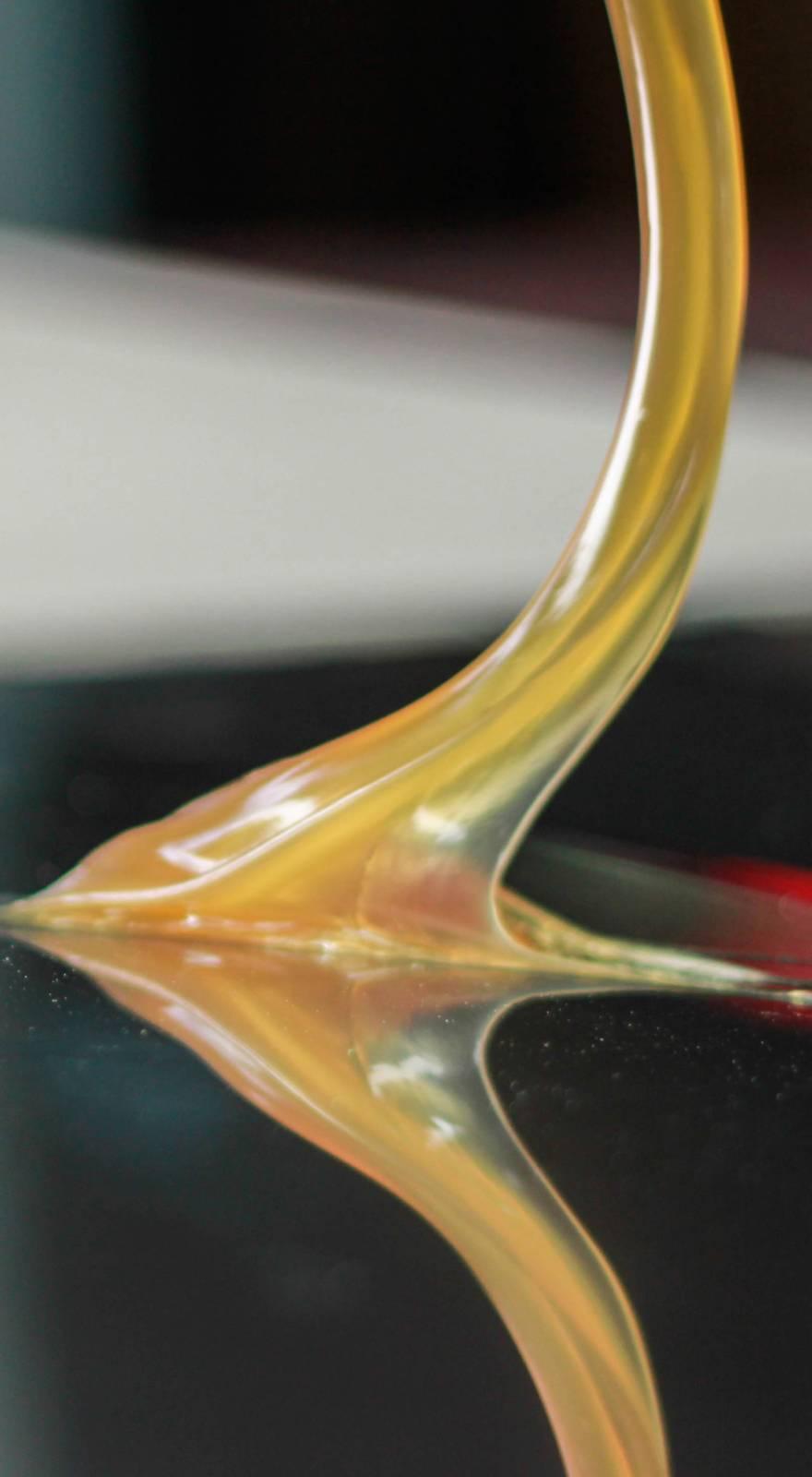

- Appearance

- Amber liquid, White liquid

- Typical Properties

- Handling Properties

| Value | Units | Test Method / Conditions | |

| Hardness | 84 | Shore D | — |

| Glass Transition Temperature | 58 | ºC | — |

| Dielectric Strength (25ºC) | 400 | volt/mil | — |

| Dielectric Constant (1 mHz) (25ºC) | 4.4 | — | — |

| Dissipation Factor (1 mHz) (25ºC) | 0.022 | — | — |

| Volume Resistivity (25ºC) | 1.0 x 10^14 | ohm-cm | — |

| Thermal Conductivity | 1.15 x 10^3 | cal cm/sec/cm2/ºC | — |

| Coefficient of Thermal Expansion (-40 – 110ºC) (in/in ºC) | 76.5 x 10^6 | — | — |

| Coefficient of Thermal Expansion (120 – 180ºC) (in/in ºC) | 144 x 10^6 | — | — |

| Viscosity (25ºC) (Part A) | 14500 | cps | — |

| Mixed Visc (25ºC) (Part A) | 2300 | cps | — |

| Density (PART A) | 12.8 | lbs./gal | — |

| Viscosity (25ºC) (Part B) | 250 | cps | — |

| Mixed Visc (25ºC) (Part B) | 2300 | cps | — |

| Density (Part B) | 7.9 | lbs./gal | — |

| Value | Units | Test Method / Conditions | |

| Mix Ratio by volume (Part A) | 100 | — | — |

| Mix Ratio by weight (Part A) | 100 | — | — |

| Gel Time (25ºC) (100 g) (PART A) | 160 | minutes | — |

| Mix Ratio by volume (Part B) | 30 | — | — |

| Mix Ratio by weight (Part B) | 19 | — | — |

| Gel Time (25ºC) (100 g) (PART B) | 160 | minutes | — |

Storage & Handling

- Handling and Mixing

LEECAST 29-192-1 can be mixed, de-aired, poured and cured at room temperature. Measure out Part A and B and mix thoroughly, scraping the sides and bottom of the container. The final mixed color is white. For void-free castings, de-air under vacuum and cast around components.

The gel time of LEECAST 29-192-1 depends on temperature and mass of material. Large masses and/or elevated temperatures will shorten the gel time. Cure can be accomplished at room temperature or with heat if faster cures are desired. Typical cure schedules for small masses are:

50oC 4 – 8 hours

80oC 1 – 2 hours- Shelf life

6 - 12 months