Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Properties

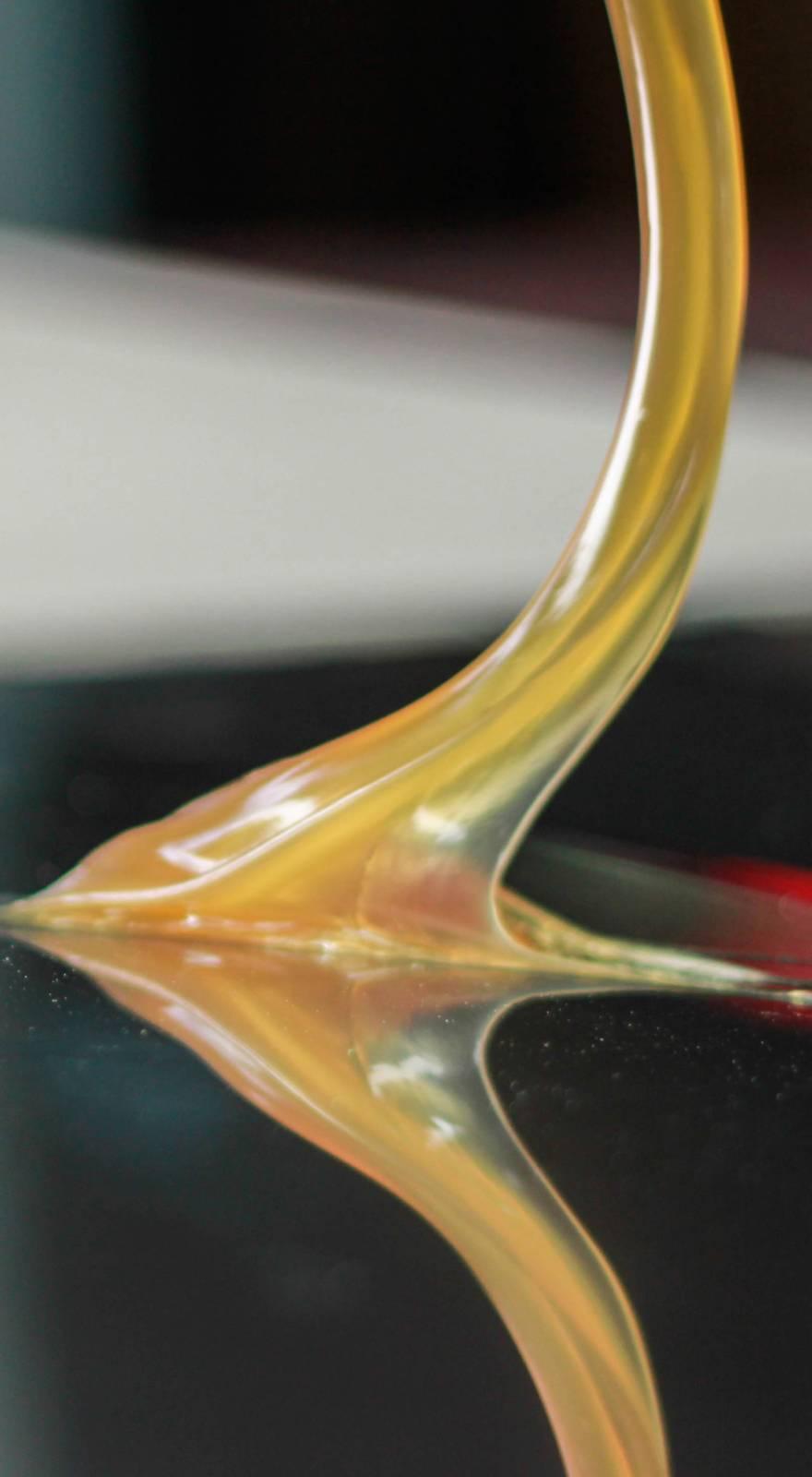

- Appearance

- Brown liqu id, Gray liquid

- Typical Properties

- Electrical Properties

- Handling Properties

| Value | Units | Test Method / Conditions | |

| Hardness | 90 | Shore D | — |

| Viscosity (25ºC) (Part A) | 30200 | cps | — |

| Density (Part A) | 14 | lbs./gal | — |

| Viscosity (25ºC) (Part B) | 300 | cps | — |

| Density (Part B) | 10 | lbs./gal | — |

| Thermal Conductivity | 9 x 10^4 | cal/cm2/cm/ºC/sec | — |

| Water Absorption (7 days at R.T) | 0.6 | % | — |

| Weight loss (7 days at 150ºC) | 0.6 | % | — |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity (25°C) | 1.5 x 10^14 | ohm-cm | — |

| Volume Resistivity (80°C) | 9.0 x 10^10 | ohm-cm | — |

| Volume Resistivity (100°C) | 8.5 x 10^10 | ohm-cm | — |

| Dissipation Factor (100 Hz) (25°C) | 0.014 | — | — |

| Dissipation Factor (100 Hz) (80°C) | 0.057 | — | — |

| Dissipation Factor (100 Hz) (100°C) | 0.055 | — | — |

| Dielectric Constant (100 Hz) (25°C) | 5.2 | — | — |

| Dielectric Constant (100 Hz) (80°C) | 5.99 | — | — |

| Dielectric Constant (100 Hz) (100°C) | 6 | — | — |

| Value | Units | Test Method / Conditions | |

| Mix Ratio, by weight (Part A) | 100 | — | — |

| Mixed Color (Part A) | Gray | — | — |

| Pot Life (25ºC) (PART A) | 15 | minutes | — |

| Gel Time (25ºC) (PART A) | 20 | minutes | — |

| Cure Time, 25ºC (Part A) | 24 | hours | — |

| Cure Time, 80ºC (Part A) | 1 | hours | — |

| Mix Ratio, by weight (Part B) | 25 | — | — |

| Mixed Color (Part B) | Gray | — | — |

| Pot Life (25ºC) (PART B) | 15 | minutes | — |

| Gel Time (25ºC) (Part B) | 20 | minutes | — |

| Cure Time, 25ºC (Part B) | 24 | hours | — |

| Cure Time, 80ºC (Part B) | 1 | hours | — |

Safety & Health

- Safety

LEECAST 30-125 is a urethane. Containers must be tightly closed to avoid contamination with moisture. Avoid skin contact with LEECAST 30-125 B which is an isocyanate. Although LEECAST 30-125 does not contain TDI or MOCA, it should be used in a well-ventilated room

Storage & Handling

- Handling and Mixing

Carefully mix and add the material taking time to scrape the side and bottom of the container. Entrapped air will rise from the mix before setting. Demold as soon as the material has set up. Full cured hardness is achieved after 24 hours at room temperature or 1 hour at 80oC

- Shelf life

6 - 12 months