Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- CAS No.

- 25068-38-6

- Technologies

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Markets

Properties

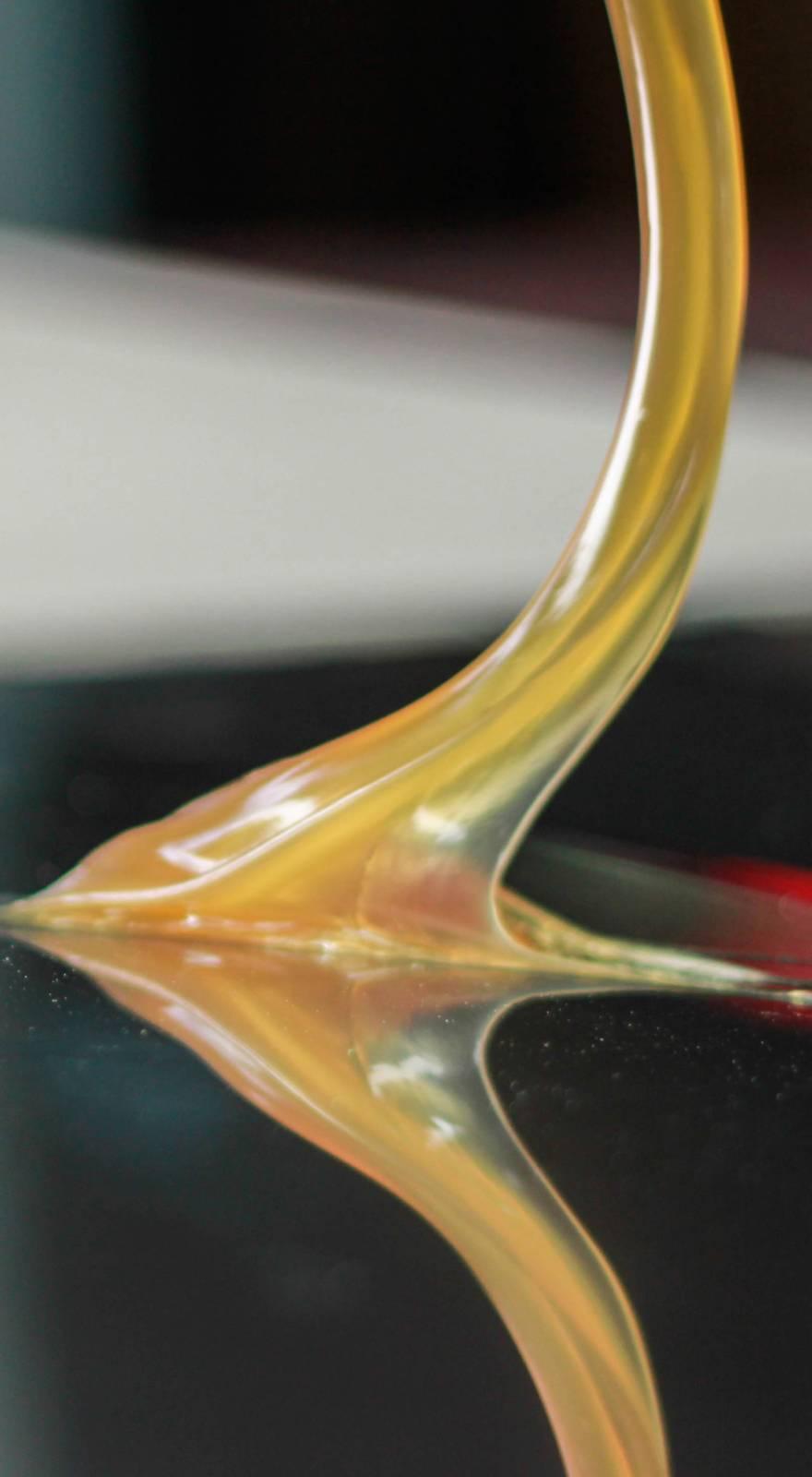

- Appearance

- Black liquid, Light gray liquid

- Typical Properties

- Handling Properties

| Value | Units | Test Method / Conditions | |

| Thixotropy (25ºC) (PART A) | 121000 | — | — |

| Viscosity (25ºC) (Part A) | 50900 | cps | — |

| Density (Part A) | 10.8 | lbs./gal | — |

| Specific Gravity (Part A) | 1.3 | g/ml | — |

| Thixotropy (25ºC) (PART B) | 146000 | — | — |

| Viscosity (25ºC) (Part B) | 45500 | cps | — |

| Density (Part B) | 12.5 | lbs./gal | — |

| Specific Gravity (Part B) | 1.5 | g/ml | — |

| Value | Units | Test Method / Conditions | |

| Hardness Part A (25ºC) | 85 | Shore D | — |

| Hardness Part B (25ºC) | 85 | Shore D | — |

| Mix Ratio, by volume (Part A) | 100 | — | — |

| Mix Ratio, by weight (Part A) | 100 | — | — |

| Gel Time (25ºC) (100 g) (PART A) | 32 | minutes | — |

| Green Strength (Part A) | 15 | hours | — |

| Full Strength (Part A) | 7 | days | — |

| Mix Ratio, by volume (Part B) | 20 | — | — |

| Mix Ratio, by weight (Part B) | 23 | — | — |

| Gel Time (25ºC) (100 g) (PART B) | 32 | minutes | — |

| Green Strength (Part B) | 15 | hours | — |

| Full Strength (Part B) | 7 | days | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Chemical Resistance

Fuel C/methanol Fuel C/ethanol Fuel C only Weight Gain, % 0.0066 0.0007 0.0004 Hardness Change, % Nil Nil Nil Compressive Strength Increase, % 1.01 0.09 0.11 1 Fume resistance, 8 days @ 25oC

- UL Crush Test

METHOD

Cylindrical specimens of LEECAST 38-191 were exposed to saturated vapors for a period of 168 hours. Following these exposures, the samples were placed between two parallel plates and crushed with a compression-testing machine having a crosshead speed of 0.1 in/min. The load was applied perpendicular to the axis of the cylindrical samples and the compressive force required to crack and break the specimens was recorded.

RESULTS

Sample Conditioning Sample Crush Force (lb.) Percent of As Received As received 3897 100 Fuel C 3633 93 Fuel A 3443 88 IRM 903 Oil 3410 88 85% Fuel C/ 15% Methanol 3510 90 85% Fuel C/ 15% Ethanol 3613 93 The resistance to crushing following sample conditioning was higher than 85 percent of the As Received value.

Storage & Handling

- Shelf life

6 months