Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Carrier Resin

Polyolefinic

Features & Benefits

- Labeling Claims

- Materials Features

- Highlights

Electrostatic charges are developed on the plastic surface because of its good electrical insulating property. These charges generally developed when surfaces are rubbed with each other or two very closely contacted surfaces are separated from each other e.g. during mold release, hot forming, removal from extrusion dies, stacking, automatic packaging etc. These charges creates problem such as dust attraction, fire & explosion hazard, difficulty in mold release, reduction of speed in packaging machine etc

- Advantages

- Outstanding thermal stability

- No yellowing / discoloration

- Ensure fast mold filling

- Easy release

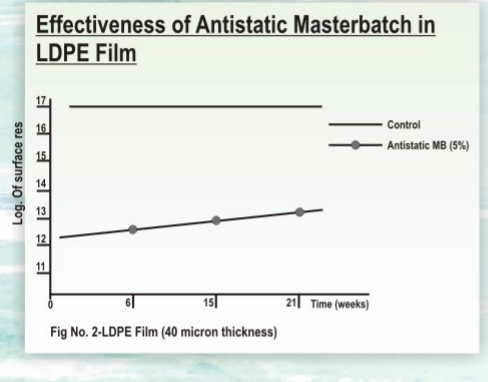

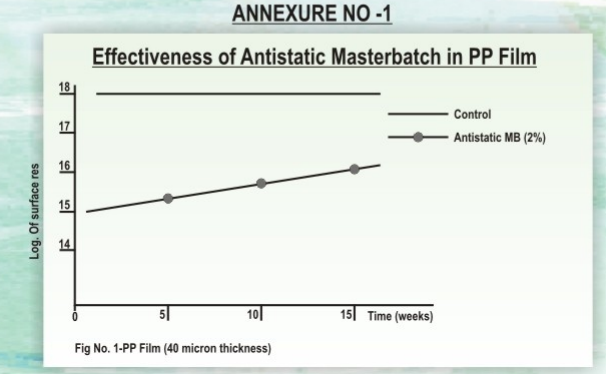

- Rapid action - effective immediately (Ref. Annexure No. 1)

- Generally recognized as safe for food contactapplication

- Gives good performance at lower dosage as shown below

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Recommended Usage

Dosage level depends on the end use application (e.g. thickness of the product, polymer used etc.) and surface resistively required. General recommendations are as give below:-

- 1-5% for LDPE/ LLDPE films

- 3-15% for PP / HDPE molded items

- PERFORMANCE OF ANTISTAT IN VARIOUS PLASTICS

POLYMER MASTERBATCH DOSAGE LEVEL SURFACE RESISTIVITY(ohms)

LLDPE 2% 3.10^10 LDPE 5% 2.10^10 HDPE 15% 2.10^11

Properties

- Physical Form

- Appearance

- Translucent White Granules

Packaging & Availability

- Packaging Type

- Packaging

Material is packed in HDPE woven sacks of 25 Kgs.