Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- CAS No.

- 93058-67-4, 1078142-02-5

- Technologies

- Product Families

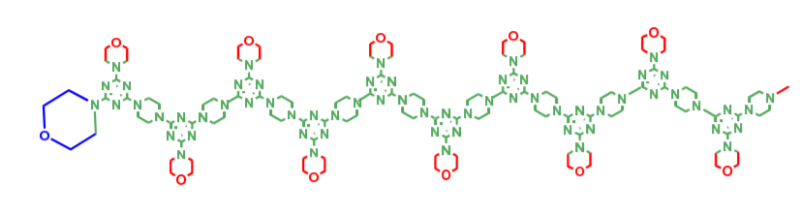

- Chemical Structure

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Recommended Applications

MCA® PPM Triazine HF is suited for PP, PE, PP copolymers, PP blends for injection molding and extrusion applications. Formulation: A total loading of 20-25% of a blend consisting of 75% ammonium polyphosphate and 25% MCA® PPM Triazine HF is usually sufficient to achieve LOI > 30% & UL 94 V0 (in addition to realizing other benefits such as low smoke density and less toxic fumes) in PP at 1.6mm. The blend of 75% ammonium polyphosphate and 25% MCA® PPM Triazine HF can also be used in polyurethane foams. It is recommended to make and use a dispersion of the blend either in polyol or isocyaanate for the application.To prevent the solids from settling, the blend suspension should be stirred or circulated by pump. The following classifications can be achieved: PU rigid foam (density > 30 kg/m3) DIN 4102-B 2 PU rigid integral skin foam (density > 200 kg/m3) DIN 4102-B 2 / UL 94-V0 PU/polyester flexible foam (density > 30 kg/m3) FMVSS 302-SE / UL 94-HF 1 Casting resins based on epoxy resins or unsaturated polyester resins also achieve the classification UL 94-V0 with the blend of 75% ammonium polyphosphate and 25% MCA® PPM Triazine HF.

Properties

- Appearance

- Free-Flowing, Off-White Crystalline Powder

- Insoluble in

- Water

- Physical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Melting Point (Infusible) | min. 290 | °C | - |

| Specific Gravity At 25°C | 1.01 | g/cm3 | - |

| Cl Content (w/w) | max. 0.1 | % | - |

| Water Content (w/w) | max. 0.5 | % | - |

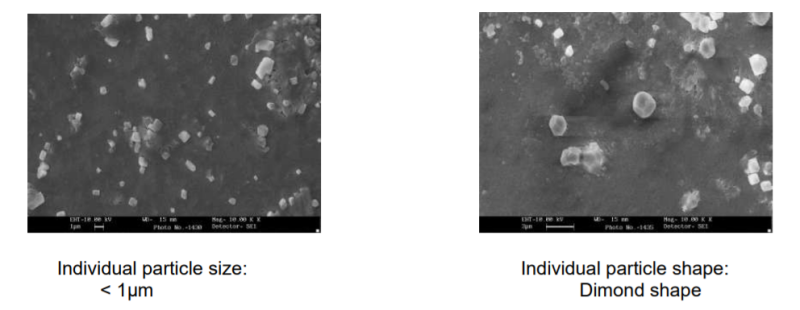

| Individual Particle Size | max. 1 | μm | - |

| Aggregated Particles (Average) | 12 | μm | - |

| TGA (Weight-loss up to 300°C) | max. 2 | % | - |

| Value | Units | Test Method / Conditions | |

| Molecular Weight | Approx. 2755 | - | - |

Technical Details & Test Data

- Scanning Electron Microscope Pictures (x10,000)

- Chemical Properties

Chemically inert and blendable with almost all additives, and particularly the HALS light stabilizers

Packaging & Availability

- Packaging Type

- Packaging

MCA® PPM Triazine HF is delivered in 25 kg paper bags

Storage & Handling

- Transport and Storage

- ADR: no restrictions.

- ADNR: no restrictions

- RID: no restrictions

- IATA: no restrictions

- IMDG: no restrictions