Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

- General Description of Antimicrobial Action (ABV)

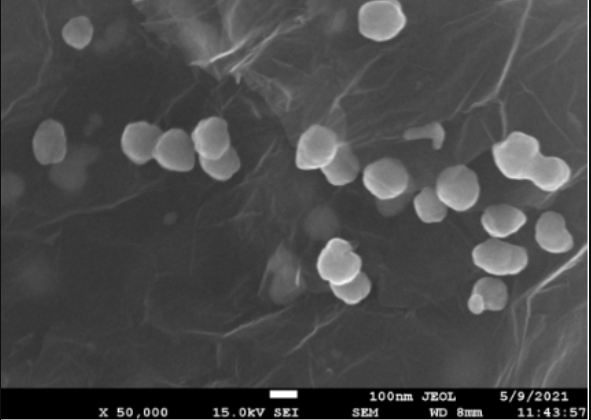

Graphene oxide is a material belonging to the family of graphene-based materials (GBM). Although in itself it has a weak bactericidal effect, in conjunction with silver particles, better results are obtained than for both materials separately. In this case, the GO film contains the particles attached to their functional groups. The high specific surface area of GO facilitates an attractive interaction with the bacterial membrane with a high degree of contact and allows the silver particles to release Ag+ ions on the bacteria in a localized manner. These ions generate ROS, which in turn destroy the respiratory system of the bacteria.

Steps of antimicrobial action:

- Ag diffusion and uptake into the bacterial cell: Accumulation and dissolution of Ag at plasma membrane cause cell leakage.

- Destabilization of Ribosomes: denatures ribosomes inhibiting protein synthesis and plasma membrane degradation.

- Enzyme interaction: AgNPs bind with the thiol group (-SH) in the respiratory enzymes and deactivate them.

- Interruption of electron transfer chain: Ag interferes with electron transport affecting the signaling pathway.

- Reactive oxygen species (ROS): Mitochondrial damage induces ROS which oxidizes proteins.

- DNA Damage. Ag binds with DNA preventing its replication and multiplication causing apoptosis.

- Cell Death: Formation of pits and perforations in the cell membrane leads to the release of cell organelles and cell death.

Features & Benefits

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

The main properties of ABV ABS (GO-Ag) are:

- Medical device housing, respiratory devices: elements or spare parts.

- Digital Anatomy: to create real human anatomy models for surgical preparation and testing of procedures with students.

- For dispensers, pillboxes, and medicine containers. Protective cases.

- Can be used as a customized protective package for patients that can bring them the flexibility to keep several medical devices or in one exclusive package

The use of a given application must be previously tested by the user, to determine its suitability.

- Recommendations for Use

- Processing temperature range: 260-310 °C. The processing temperature is directly related to the printing speed. The faster the processing speed is, the higher the temperature of the print fuser should be.

- Recommended bed temperature: 90-100 °C. If the adherence to the building platform is weak, it is recommended to use products to improve the adherence between the piece and the machine.

- Layer fan speed: 0%.

- Heated chamber temperature: not necessary (if available, use it at more than 45°C). It is advisable to use totally closed printers to prevent internal stresses produced by the cooling of the parts from causing undesired breakage or deformation.

- Drying conditions: 80°C for at least 4 hours. Drying of the material is recommended if signs of moisture are detected in the print.

- Printing speed: 30-60 mm/s. This parameter will depend on the final quality that is expected to be achieved as well as the stability of the printing machine itself.

- Nozzle size: 0.4-0.6 mm. To prevent excessive wear of the extrusion components, special hardened or stainless steel nozzles should be used.

- Due to the reinforcement found in the material itself, this can lead to nozzle clogging. To eliminate this problem, the filament shrinkage must be used cautiously, even to the point of eliminating it.

Properties

- Color

- Typical Properties

- Material Properties

This product has all the regulatory compliance necessary for healthcare applications, furthermore has higher structural stability and very high fluidity. The specific characteristics of ABV ABS are:

- Contain (GO- Ag), these components inhibit the growth of bacteria, viruses, algae, fungi, or mold. It´s a powerful antimicrobial.

- Contains pure graphene oxide with the optimal size and concentration to maintain the excellent mechanical properties of the polymer.

- Hydrophobic material that emphasizes impact resistance as well as abrasion resistance to lipids, cleaning, and disinfectant agents.

- The graphene blocks the contraction, deformation, and also blocks

- The lifting of the upper board layers. This gives the material a structure and a density that allows producing complex geometric structures.

- Also noteworthy is the increase in melting temperature, the wide range of temperatures it can withstand without degradation, and the increase in heat dissipation.

| Value | Units | Test Method / Conditions | |

| Layer Fan Speed | 0.0 | % | — |

| Nozzle Size | 0.4 - 0.6 | mm | — |

| Printing Speed | 30 - 60 | mm/s | — |

| Processing Temperature Range | 260 - 310 | °C | — |

| Recommended Bed Temperature | 90 - 100 | °C | — |

Regulatory & Compliance

- Certifications & Compliance