Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Key Attributes

- UL HB Recognition (File # E36952)

- Fast cure—modified alkoxy (neutral) cure

- Primerless adhesion to many plastics, metals, wood, glass, and ceramics

- Provides electrical insulation

- Excellent chemical and weather resistance

- High strength

- Suited for marine applications

Applications & Uses

- Applications

- Cure Method

- Application Instructions

The 1035 can be dispensed via caulking cartridges by manual caulking or air operated guns. The adhesive sealant should be applied in a less than 6 mm (1/4 in) diameter bead or ribbon around the edge of the surface to be bonded.

To apply the adhesive sealant

- Clean and dry the surface of the substrate to remove oil, dust, water, solvents, and other contaminants.

- Apply the adhesive sealant, ensuring adequate coverage and desired thickness.

- Allow a full cure at room temperature for at least 24 hours.

Attention :Exact cure time will vary depending on temperature, humidity, and thickness.

Note :Adequate bond strength will develop in 4-6 hours to permit handling of parts.

Properties

- Odor

- Ammonia-like

- Physical Properties

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Cured Properties

- Note

Mechanical Properties : Cured at 25 °C [77 °F] and 50% relative humidity for 7 days.

Electrical Properties :Information is provided for customer convenience. The properties are not tested on a routine basis.

Thermal Properties :Information is provided for customer convenience. The properties are not tested on a routine basis.

| Value | Units | Test Method / Conditions | |

| Color | Translucent | — | — |

| Flexibility | Excellent | °C (°F) | — |

| Flammability | HB | — | — |

| Viscosity | Paste | — | — |

| Specific Gravity | 1.04 | % | — |

| Flash Point | 100 (230) | °C (°F) | — |

| Value | Units | Test Method / Conditions | |

| Hardness, Shore A | 24 | — | — |

| Elongation | 435 | % | — |

| Tear Strength | 7.1 | kg/cm | — |

| Peel Strength Glass | 7.5 | kg/cm | — |

| Peel Strength Aluminum | 8.6 | kg/cm | — |

| Lexan Polycarbonate | 7.1 | kg/cm | — |

| PVC | 8 | kg/cm | — |

| Value | Units | Test Method / Conditions | |

| Coefficient of Thermal Expansion | 300 | ppm/°C | — |

| Thermal Conductivity | 0.06 | W/(m·K) | — |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity | 2 x 10¹⁵ | Ω·cm | — |

| Dielectric Constant (at 100 MHz) | 2.8 | — | — |

| Dissipation Factor (at 100 Hz) | 0.002 | — | — |

| Brittle Point | -60 (-75) | °C (°F) | — |

| Value | Units | Test Method / Conditions | |

| Tensile Strength | 21 | kg/cm2 | — |

| Dielectric Strength | 17 | kv/mm (v/mil) | — |

Technical Details & Test Data

- Compatibility

A primer is not required; however, for difficult to bond substrates, a primer is recommended.

Note: Not recommended for use on polycarbonates and acrylics. Will discolor sensitive metals (copper and brass) only when in direct contact.

The 1035 is compatible with most materials found on printed circuit assemblies; however, in an uncured state it is not compatible with contaminants like water, oil, and greasy flux residues. Therefore, it is extremely important to clean the printed circuit assembly thoroughly with a suitable electronic cleaner before applying the coating.

Attention :Perform a compatibility test in a representative environment prior to use to determine if other incompatibilities may be present.

- Usage Parameters

Properties Value Tack Free 15 min Full Cure (22°C [72°F]) 24 h Application Rate 360 gm/min

Safety & Health

- Areas of Application

Please see the 1035 Safety Data Sheet (SDS) for more details on transportation, storage, handling and other security guidelines.

Health and Safety: Suspected of damaging fertility or the unborn child. May cause an allergic skin reaction. Avoid breathing vapors. Wear protective gloves/protective clothing. Contaminated work clothing should not be allowed out of the workplace.

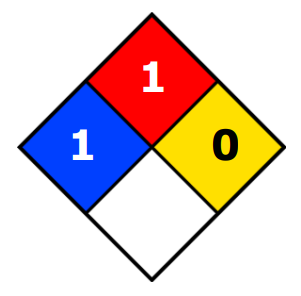

HMIS® RATING

NFPA® 704 CODES

Approximate HMIS and NFPA Risk Ratings Legend : 0 (Low or none); 1 (Slight); 2 (Moderate); 3 (Serious); 4 (Severe)

Packaging & Availability

- Packaging Type

- Packaging and Supporting Products

Cat. No. Packaging Net Weight Net Volume 1035-85ML Tube 88.1 g 85 mL 1035-85MLCA Tube 88.1 g 85 mL

Storage & Handling

- Shelf Life

- 2 Years

- Storage

Store between 16 and 27 °C [60 and 80 °F] in dry area away from sunlight.

- Temperature Ranges

Properties Value Storage Temperature 16 to 27 °C [60 to 80 °F]