Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Details

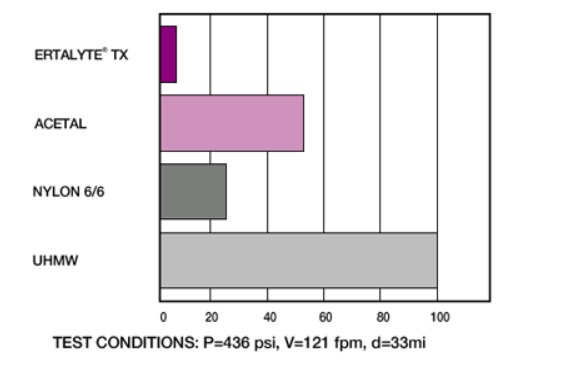

Ertalyte® TX is an internally lubricated thermoplastic polyester providing enhanced wear and inertness over general purpose nylon(PA) and acetal(POM) products. Containing uniformly dispersed solid lubricant, Ertalyte® TX provides a lower wear rate and coefficient of friction than unmodified polyesters like PET or PBT and even internally lubricated materials like Delrin® AF blend.

Ertalyte® TX excels under both high pressure and velocity conditions. It is also ideally suited for applications involving soft metal and plastic mating surfaces. Ertalyte® TX is also FDA and USDA compliant.

- Product Overview

- Outstanding wear resistance

- Non-staining

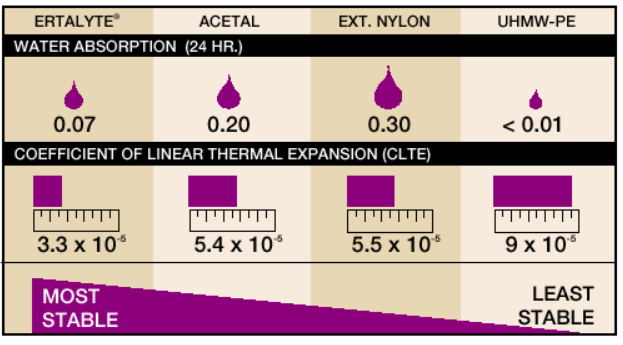

- Excellent dimensional stability

- FDA compliant

- Low and constant coefficient of friction

- Low moisture absorption

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Product Applications

- Linear Bearings, Wear and Slide Pads, Dynamic Seals, Scraper Blades, Thrust Washers, Valve Seats, Rollers and Wheels without Bearings, Journal Bearings

- Distribution Valves - Ertalyte® TX excels under both high pressure and velocity conditions. It is also ideally suited for applications involving soft metal and plastic mating surfaces. The distribution valves in this food packing machinery are made of KETRON® PEEK-1000 and ERTALYTE TX. These materials are replacing stainless steel parts which caused too much wear of the housing and consequently unacceptable maintenance costs. The clearance between distribution shaft and housing must be kept as tight as possible to avoid leakage (Prior material: Stainless Steel).

Properties

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

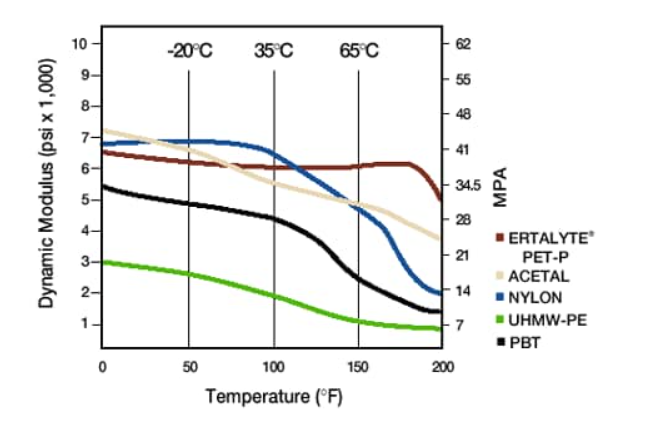

- Ertalyte Offers Better Strength in Higher Temperatures

- Wear Rate (k-Factor)

- Stability of Engineering Materials