Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Benefits

- Flexural modulus of over 1,000,000 psi

- Available in 10” x 10” plates of 6mm, 9mm or 12mm thick

- Tensile elongation of 3.0% for precise hole placement

- Extremely stable during usage, CTE of 1.85 (x10⁻⁵th)

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

Properties

- Physical Form

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Miscellaneous Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity (73˚F) | 1.52 | — | ASTM D792 |

| Tensile Strength (At Break, 73˚F) | 16000 | psi | ASTM D638 |

| Tensile Modulus of Elasticity (73˚F) | 1100000 | psi | ASTM D638 |

| Tensile Elongation (At break, 73˚F) | 3 | % | ASTM D638 |

| Shear Strength (73˚F) | 11000 | psi | ASTM D732 |

| Flexural Strength (73˚F) | 24000 | psi | ASTM D790 |

| Flexural Modulus of Elasticity (73˚F) | 1100000 | psi | ASTM D790 |

| Compressive Strength (10% Deformation, 73˚F) | 23000 | psi | ASTM D695 |

| Compressive Modulus of Elasticity (73˚F) | 600000 | psi | ASTM D695 |

| Hardness (73˚F) | M100/R123 | Rockwell | ASTM D785 |

| Notched Izod (Notched, 73˚F) | 0.7 | ft.lb./in² | ASTM D256 Type “A” |

| Value | Units | Test Method / Conditions | |

| Coefficient of Linear Thermal Expansion | 1.85 x 10⁻⁵ | in./in./°F | ASTM E-831 (TMA) |

| Heat Deflection Temperature (264 psi) | 445 | °F | ASTM D648 |

| Melting Point (Crystalline) - Peak | 644 | °F | ASTM D3418 |

| Continuous Service Tempearature in Air (1) | max. 480 | °F | — |

| Thermal Conductivity | 2.36 | BTU in./(hr. ft² ˚F) | ASTM F433 |

| Value | Units | Test Method / Conditions | |

| Surface Resistivity | min. 10¹³ | ohms/square | EOS/ESD S11.11 |

| Flammability (1.5mm) (2) (3) | V-0 | — | UL-94 |

| Value | Units | Test Method / Conditions | |

| Water Absorption Immersion (Saturation) (2) | 0.44 | % by wt. | ASTM D570 |

Technical Details & Test Data

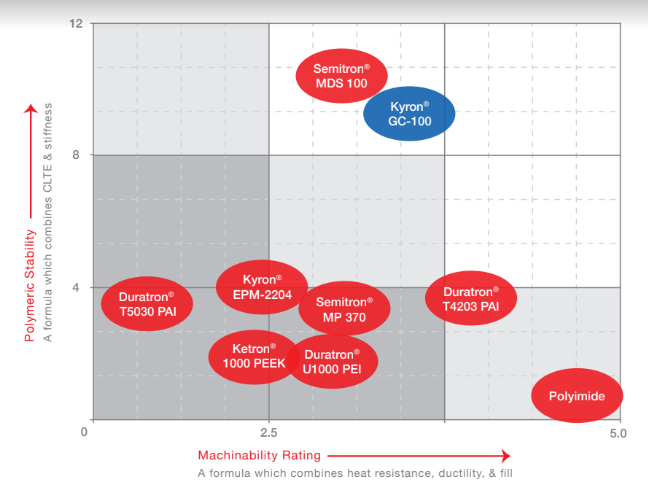

- Kyron® GC-100 Product Positioning

Socket Type Basic Challenging Demanding Hole Size 0.6 - 0.4 0.4 - 0.3 0.3 - 0.1 Pitch Size 1.0 - 0.35 0.35 - 0.25 0.25 - 0.18 Wall 0.2 0.2 - 0.1 0.05 - 0.01 I/0 Count 1000 2500 2500+ - Test Socket Material Vs. Other Materials

- Versus GF-PAI – Kyron® GC-100 provides the stiffness of GF PAI with improved small hole machinability & lower moisture absorption.

- Versus Standard Polyimides – Kyron® GC-100 offers 2X higher stiffness, 2.5X less moisture absorption, 35% lower CTE and 2X better hole accuracy.

- Versus MDS-100 – Designed to complement MDS-100, offers relatively similar properties but available in thicker cross sections.

- Note

- (1) Data represents Mitsubishi Chemical Advanced Materials estimated maximum long-term service temperature based on practical field experience.

- (2) Specimens: 1/8” thick x 2” diameter or square.

- (3) Estimated rating based on available data. The UL-94 Test is a laboratory test and does not relate to actual fire hazard.