Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Key Features

- Good processability in blown film fabrication or cast film extrusion process using an existing LDPE film production machine.

- Low gel content.

- Good dispersibility with other biodegradable polymers, i.e. PBS(A), PBAT, PLA, PHA, Starch, etc.

- Suitable for film applications, i.e. shopping bag, compost bag, mulch film, food packaging, etc.

- Good transparency, strong tear strength, high elongation at break.

Applications & Uses

- Markets

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Cast Film Extrusion Properties

- Press Film Properties

- Blown Film Fabrication Properties

- Cast Film Properties

- Blown Film Properties

- Pellet Properties

- Note

* - Typical properties of blown film of PBST SA916F / BioPBS FZ91PM (70 wt% / 30 wt%)

| Value | Units | Test Method / Conditions | |

| Temperature | 125 - 170 | °C | — |

| Die Lip Gap | 0.5 - 1.0 | mm | — |

| Roll Temperature | 25 - 50 | °C | — |

| Value | Units | Test Method / Conditions | |

| Thickness | 99.0 | µm | — |

| Young Modulus | 68.0 | MPa | ISO 527-3 |

| Yield Stress | 6.0 | MPa | ISO 527-3 |

| Tensile Strength | 36.0 | MPa | ISO 527-3 |

| Elongation at Break | 800.0 | % | ISO 527-3 |

| Elmendorf Tear Strength | 100.0 | N/mm | ISO 6383-2 |

| Value | Units | Test Method / Conditions | |

| Temperature | 125 - 160 | °C | — |

| Die Lip Gap | 0.8 - 1.8 | mm | — |

| Blow Up Ratio | 2.0 - 4.5 | — | — |

| Value | Units | Test Method / Conditions | |

| Thickness | 30.0 | µm | ISO 1183 |

| Young Modulus (machine direction) | 92.0 | MPa | ISO 527-3 |

| Young Modulus (transverse direction) | 128.0 | MPa | ISO 527-3 |

| Yield Stress (machine direction) | 13.0 | MPa | ISO 527-3 |

| Yield Stress (transverse direction) | 9.0 | MPa | ISO 527-3 |

| Tensile Strength (machine direction) | 49.0 | MPa | ISO 527-3 |

| Tensile Strength (transverse direction) | 37.0 | MPa | ISO 527-3 |

| Elongation at Break (machine direction) | 280.0 | % | ISO 527-3 |

| Elongation at Break (transverse direction) | 920.0 | % | ISO 527-3 |

| Elmendorf Tear Strength (machine direction) | 2.0 | N/mm | ISO 6383-2 |

| Elmendorf Tear Strength (transverse direction) | 170.0 | N/mm | ISO 6383-2 |

| Puncture Impact Strength | 38000.0 | J/m | MCC method |

| Value | Units | Test Method / Conditions | |

| Blow Up Ratio* | 2.5 | — | — |

| Thickness* | 32.0 | µm | — |

| Young Modulus (machine direction)* | 210.0 | MPa | ISO 527-3 |

| Young Modulus (transverse direction)* | 270.0 | MPa | ISO 527-3 |

| Yield Stress (machine direction)* | 17.0 | MPa | ISO 527-3 |

| Yield Stress (transverse direction)* | 14.0 | MPa | ISO 527-3 |

| Tensile Strength (machine direction)* | 57.0 | MPa | ISO 527-3 |

| Tensile Strength (transverse direction)* | 52.0 | MPa | ISO 527-3 |

| Elongation at Break (machine direction)* | 530.0 | % | ISO 527-3 |

| Elongation at Break (transverse direction)* | 770.0 | % | ISO 527-3 |

| Elmendorf Tear Strength (machine direction)* | 2.0 | N/mm | ISO 6383-2 |

| Elmendorf Tear Strength (transverse direction)* | 92.0 | N/mm | ISO 6383-2 |

| Puncture Impact Strength* | 29000.0 | J/m | MCC method |

| Value | Units | Test Method / Conditions | |

| Melt Flow Rate (at 190°C, 21.2 N) | 3.5 - 4.0 | g/10 min | ISO 1133 |

| Melting Point | 110.0 | °C | DSC |

| Glass Transition Temperature | -20.0 | °C | DSC |

| Density | 1.26 | g/cm³ | ISO 1183 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

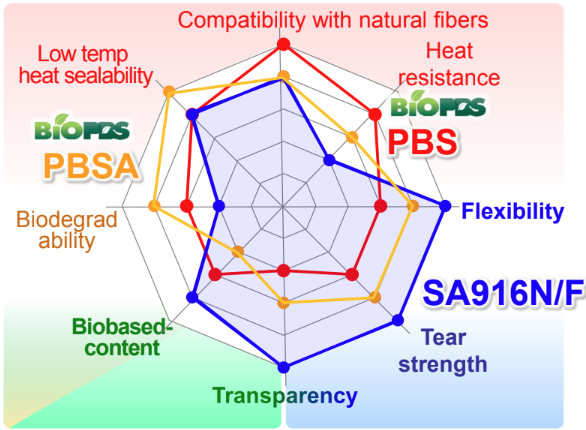

- Property Features Comparison

Packaging & Availability

- Regional Availability

- Packaging Information

- PBST SA916F pellets are dried and packed in aluminum-lined packaging.

- Available in 25 kg bags

Storage & Handling

- Storage Conditions

- Do not store outdoors. Keep dry at ambient temperature.

- Avoid humid environment, heat and direct sunlight.

- Use material as soon as possible after the delivery, in order to prevent possible material quality deterioration.

- Pre-dry of the unopened PBST SA916F is not necessary.

- It is recommended to keep packages sealed until ready to process and using up the whole 25-kg bag.

- Unused material should be tightly sealed, kept away from open air, and pre-dried (at 60°C for over 5 hours) to moisture content of less than 1,000 ppm (preferable less than 500 ppm) prior to using next time.