Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 155-04-4

- EC No.

- 205-840-3

- Technologies

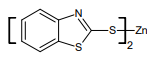

- Structure

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Equivalent to

- Vulkacit® ZMC

- Vulkacit® ZM-2

Properties

- Appearance

- White to Light-yellowish powder

- Typical Properties

- Specifications

| Value | Units | Test Method / Conditions | |

| Density (20°C) | 1700 | kg/m3 | — |

| Value | Units | Test Method / Conditions | |

| Melting Point Initial | min. 200 | °C | — |

| Free MBT | 14-18 | % | — |

| Heating Loss | max. 0.3 | % | — |

| Zinc Content | 15.0-18.0 | % | — |

| Residue (150μm sieve) | max. 0.10 | % | — |

Regulatory & Compliance

- Certification

ISO 9001

Packaging & Availability

- Packaging Type

- Packaging

25kg paper bag or other bags customer needed.

Storage & Handling

- Shelf Life

- 24 months