Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- ProtectS your electronics components from static shocks thanks to the Nanovia ABS ESD filament. This filament prevents the accumulation of static electricity by progressively discharging itself through its composite carbon black structure.

- Ideal for housing and protecting hard drives as well as creation of electronic connectors.

- Advantages

- Protects from static electricity shocks.

- Conductive.

- Thermal resistance.

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Application Recommendations

Printing

With it’s printing settings close to standard, the Nanovia ABS ESD filament can be used on most commercially available 3D printers.

Post treatment

To preserve the fillament’s ESD properties, pieces should not be covered using insulating paints.

Properties

- Physical Form

- Mechanical Properties

- Typical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.05 | g/cm3 | ISO 1183 |

| Elongation at Break | 10.0 | % | ISO 527 |

| Flexual Modulus | 1900.0 | Mpa | ISO 178 |

| Hardness | 77.0 | Shore D | — |

| Value | Units | Test Method / Conditions | |

| Extrusion Temperature (3D Printing) | 240 - 260 | °C | — |

| Plate Temperature (3D Printing) | 100 - 120 | °C | — |

| Enclosure Temperature (3D Printing) | 90.0 | °C | — |

| Nozzle (3D Printing) | All | — | — |

| Printing speed (3D Printing) | 20 - 60 | mm/s | — |

| Linear Weight (3D Printing, Ø 1.75 mm) | 2.6 | g/m | — |

| Linear Weight (3D Printing, Ø 2.85 mm) | 8.6 | g/m | — |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | 100.0 | °C | — |

| DTUL (1.8 MPa) | 88.0 | °C | — |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity | max. 10^5 | Ω cm | PRE021 |

| Surface Resistance | max. 10^6 | Ω | IEC |

Safety & Health

- Health and Safety

Printing

We recommend printing Nanovia ABS ESD in a room equipped with air extraction or by using appropriate breathing equipment. Whilst printing ABS produces a VOC derivative of styrene.

Post treatmentWe recommend wearing standard safety equipment during the post treatment of your prints made with Nanovia ABS ESD.

Packaging & Availability

- Packaging Type

- Packing

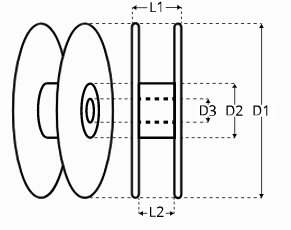

Spools are packed in individual boxes, sous-vide with desiccant. Spools are equipped with both material traceability and a production series number.

Other sizes are available up to 25kg on demand.

Spool L1 L2 D1 D2 D3 Weight 500g 55 45 200 105 52 252 g 2kg 100 90 300 210 52 640 g

Storage & Handling

- Storage

- Store Nanovia ABS ESD in a dry and dark location, if possible with a desiccant.

- In order to guarantee good printing conditions dehydrate Nanovia ABS ESD at 60°c for 4 hours or longer, when the spools has been exposed to moisture for an extended period.