Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Advantages

- Insulating.

- Certified non flammable V-0 UL94.

- UV and oxydation resistant.

- Alkali, acid, bases, ionic, alcohol resistant.

- Suited for outdoor use.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Physical Form

- Mechanical Properties

- Typical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.08 | g/cm3 | ISO 1183 |

| Tensile Modulus | 67.0 | Mpa | ISO 527 |

| Flexual Modulus | 2430.0 | Mpa | ISO 527 |

| Elongation at Break | 20.0 | % | ISO 178 |

| Moisture Absorption | 0.1 | mm | — |

| Warping | 0.5 - 0.7 | % | — |

| Value | Units | Test Method / Conditions | |

| Extrusion Temperature (3D Printing) | 260 - 280 | °C | — |

| Plate Temperature (3D Printing) | 130 - 150 | °C | — |

| Enclosure Temperature (3D Printing) | 110.0 | °C | — |

| Nozzle (3D Printing) | All | — | — |

| Printing speed (3D Printing) | 50 - 70 | mm/s | — |

| Linear Weight (3D Printing, Ø 1.75 mm) | 2.6 | g/m | — |

| Linear Weight (3D Printing, Ø 2.85 mm) | 7.0 | g/m | — |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | 140.0 | °C | — |

| DTUL | 114.0 | °C | ISO 75/A |

| Flammability (1.6 mm) | V0 | — | UL 94 |

| Flammability (2.5 mm) | 5VA | — | UL 94 |

| Value | Units | Test Method / Conditions | |

| Dielectric Constant (100 Hz) | 2.9 | — | — |

| Dielectric Constant (1MHz) | 2.9 | — | IEC60250 |

| Dissipation Factor (100 Hz) | 0.0003 | — | — |

| Dissipation Factor (1 MHz) | 0.0004 | — | IEC60250 |

| Dielectric Strength | 29.0 | kV/mm | IEC60243 |

| Volume Resistivity | 10.10^15 | Ω | IEC60093 |

| Surface Resistivity | 10 x 10^15 | Ω | IEC60093 |

| Tracking Resistance | 190.0 | V | IEC60112 |

Regulatory & Compliance

- Certifications & Compliance

- Certification

Certified UL94

- Nanovia Insublend filament , halogen free, is certified non flammable V-0 (@ 1,6 mm with a 5VA @ 2.5mm index) and flame retardant according to the UL 94 certification *.

- UL 94 is a security certification for plastic materials. V-0 classification = no combustion after 10 seconds of vertical exposure to a flame.

Technical Details & Test Data

- Chemical resistance at 20°C

Acids Boiling water Excellent Hydrochloric acid (solution at 50%) Excellent Sulphuric Acid (solution at 50%) Excellent Nitric acid (solution at 50%) Excellent Phosphoric acid (solution at 60%) Excellent Acetic acid Excellent Alcohols Isopropyl Good Methanol Excellent Ethanol Excellent Ionic aqueous solution

Brine (satured NaCl) Excellent Ammonium phosphate Excellent Bases Ammonia (solution at 10% NH3) Excellent Caustic soda (solution with 10% NaOH) Excellent Cetones Acetone Weak MethylEthylKetone Weak Aromatics Toluene Weak Xylene Weak Hydrocarbons Cyclohexane and n-Hexane Weak n-Heptane Moderate Liquid paraffin Moderate Diesel fuel Moderate Kerosene Weak Lubrifiants Moderate Greases Weak Solvents Carbon tetrachloride Weak Chloroform Weak Tributyl phosphate Phosphate Ethyl acetate Weak

Safety & Health

- Health and Safety

Printing

We recommend printing Nanovia ABS AF in a room equipped with air extraction or by using appropriate breathing equipment. Whilst printing ABS produces a VOC derivative of styrene.

Post treatmentWe recommend wearing standard safety equipment during the post treatment of your prints made with Nanovia ABS Insulblend.

Packaging & Availability

- Packaging Type

- Packing

Spools are packed in individual boxes, sous-vide with desiccant. Spools are equipped with both material traceability and a production series number.

Other sizes are available up to 25kg on demand.

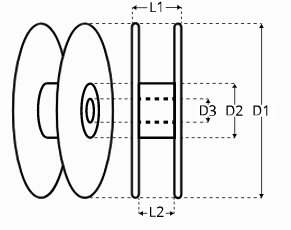

Spool L1 L2 D1 D2 D3 Weight 500g 55 45 200 105 52 252 g 2kg 100 90 300 210 52 640 g

Storage & Handling

- Storage

Printing

- Store Nanovia Insublend in a dry and dark location, if possible with a desiccant.

- In order to guarantee good printing conditions dehydrate Nanovia Insublend at 60°c for 4 hours or longer, when the spools has been exposed to moisture for an extended period.