Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- With a glass transition temperature of 140°C and certified fire resistant UL 94 V0, Nanovia PC-V0 allows for both mechanical and fire resistant 3D prints.

- This filament has been specially composed to be non-flammable certified V0 at 3mm.

- Advantages

- Great fire resistance.

- Heat resistance up to 140°C.

- Shock resistant.

- Good mechanical properties.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Application Recommendations

Post treatment

For an outdoor usage, it’s recommended either paint or apply a protective UV coating, to prevent the polycarbonate from hydrolyzing and yellowing.

Properties

- Flame Rating

- Physical Form

- Mechanical Properties

- Typical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.13 | g/cm3 | ASTM D792 |

| Tensile modulus | 700.0 | Mpa | ISO 527 |

| Flexual Modulus | 2000.0 | Mpa | ISO 178 |

| Elongation at Break | 120.0 | % | ISO 527 |

| IZOD (Notched) | 65.0 | KJ/m2 | — |

| Value | Units | Test Method / Conditions | |

| Extrusion Temperature (3D Printing) | 260 - 290 | °C | — |

| Plate Temperature (3D Printing) | 100 - 140 | °C | — |

| Enclosure Temperature (3D Printing) | min. 100 | °C | — |

| Nozzle (3D Printing) | All | — | — |

| Printing speed (3D Printing) | 20 - 60 | mm/s | — |

| Diameter | 1.75 (+/- 50) | mm(µm) | — |

| Warping | 0.5 - 0.7 | % | — |

| Humidity Absorption | 0.15 | % | D570 |

| Linear Weight (3D Printing, Ø 1.75 mm) | 2.73 | g/m | — |

| Linear Weight (3D Printing, Ø 2.85 mm) | 7.23 | g/m | — |

| Value | Units | Test Method / Conditions | |

| MFI (300°C, 1.2 kg) | 2021-10-10 | g/min | D1238 |

| Heat Deflection Temperature (4.6 kg/cm2) | 144.0 | °C | D648 |

| Heat Deflection Temperature (18.6 kg/cm2) | 50.0 | °C | D648 |

| Thermal expansion | 5.5 x 10^-5 | mm/mm/°C | D696 |

| Flammability (3.0 mm) | V-0 | — | UL 94 |

| Fusion Temperature | 300.0 | °C | — |

| Glass Transition Temperature | 120.0 | °C | — |

| Value | Units | Test Method / Conditions | |

| Resistivity Volume | 4×10^16 | Ω.cm | D257 |

| Dielectric Strength | 30.0 | kV/mm | D149 |

| Dielectric Constant D150 | 2.8 | — | — |

| Dissipation Factor D150 | 0.0082 | — | D150 |

| ARC Resistance | 120.0 | sec | — |

Regulatory & Compliance

- Certifications & Compliance

Safety & Health

- Health and Safety

Printing

We recommend printing Nanovia PC-V0 in a room equipped with air extraction or by using appropriate breathing equipment.

Post treatmentWe recommend wearing standard safety equipment during the post treatment of your prints made with Nanovia PC-V0.

Packaging & Availability

- Packaging Type

- Packing

Spools are packed in individual boxes, sous-vide with desiccant. Spools are equipped with both material traceability and a production series number.

Other sizes are available up to 25kg on demand.

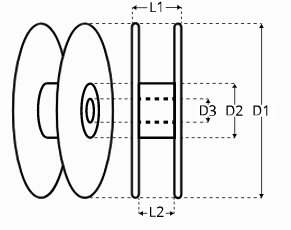

Spool L1 L2 D1 D2 D3 Weight 500g 55 45 200 105 52 252 g 2kg 100 90 300 210 52 640 g - Availability

Nanovia PC-V0 is available in the following colors:

- Translucid.

- White.

- Black.

Storage & Handling

- Storage

- Store Nanovia PC-V0 in a dry and dark location, if possible with a desiccant.

- In order to guarantee good printing conditions dehydrate Nanovia PC-V0 at 100 °C for 4 hours or longer, when the spools has been exposed to moisture for an extended period.