Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Advantages

- High chemical resistance.

- Low friction coefficient.

- Usuable up to 160°C.

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Physical Form

- Mechanical Properties

- Typical Properties

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.79 | g/cm3 | ISO 1183 |

| Elongation at Break | 200 - 750 | % | ISO 527 |

| Value | Units | Test Method / Conditions | |

| Enclosure Temperature (3D Printing) | 245 - 265 | °C | — |

| Plate Temperature (3D Printing) | 90 - 110 | °C | — |

| Nozzle (3D Printing) | All | — | — |

| Diameter | 1.75 (+/- 50) | mm(µm) | — |

| Linear Mass (3D Printing, Ø 1.75 mm) | 2.4 | g/m | — |

| Linear Mass (3D Printing, Ø 1.75 mm) | 6.38 | g/m | — |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | -40.0 | °C | — |

| Fusion Temperature | 170 - 180 | °C | — |

| Flamability (1.5mm) | V-0 | — | UL 94 |

Regulatory & Compliance

- Certifications & Compliance

Safety & Health

- Health and Safety

Impression

We recommend printing Nanovia PVDF in a room equipped with air extraction or by using appropriate breathing equipment.

Post treatmentWearing standard safety equipment during the post treatment of prints made with Nanovia PVDF is recommended.

Packaging & Availability

- Packaging Type

- Packing

Spools packed in individual boxes, sous-vide with desiccant. Product equipped with material traceability and production series number.

Other formats up to 25kg are available on request.

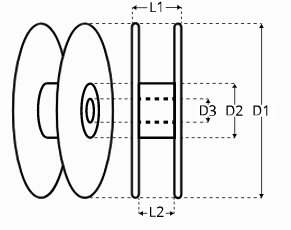

Spool L1 L2 D1 D2 D3 500g 55 45 200 105 52 2kg 100 90 300 210 52

Storage & Handling

- Storage

PVDF is a hydrophopic polymer and thus does not require any particular protection from moisture during storage. Nor does it needs to be dehydrated before printing.