Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Advantages

- Great flexibility.

- Excellent inter-layer adhesion.

- Shock resistant.

- Easy to print.

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Usage Tips

Post treatment

Nanovia TPE 22D cannot be sanded.

Properties

- Physical Form

- Mechanical Properties

- Typical Properties

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.66 | g/cm3 | ISO 1183 |

| Traction Modulus | 12.0 | MPa | ISO 527-1 |

| Hardness | 22.0 | Shore D | — |

| Value | Units | Test Method / Conditions | |

| Extrusion Temperature (3D Printing) | 220 - 240 | °C | — |

| Plateau Temperature (3D Printing) | 20 - 40 | °C | — |

| Nozzle (3D Printing) | All | — | — |

| Printing speed (3D Printing) | 20 - 60 | mm/s | — |

| Linear Mass (3D Printing, Ø 1.75 mm) | 3.99 | g/m | — |

| Linear Mass (3D Printing, Ø 1.75 mm) | 10.59 | g/m | — |

| Value | Units | Test Method / Conditions | |

| Usable Up to | 50.0 | °C | — |

Technical Details & Test Data

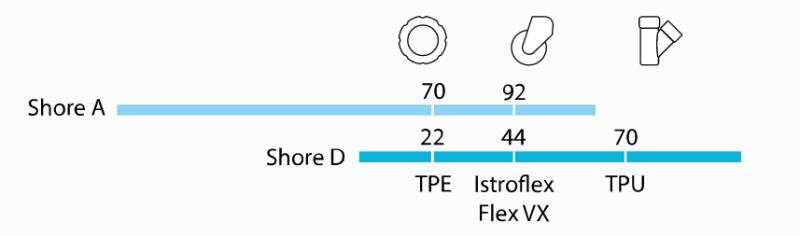

- Nanovia Hoses

- Shore D 22 - Nanovia TPE 22D.

- Shore D 44 - Nanovia Istroflex & Flex VX.

- Shore D 70 - Nanovia TPU 70D.

Safety & Health

- Health and Safety

Impression

It is advisable to print this material in an area equipped with air extraction or suitable protection. When printing, TPE can lead to the release of VOCs.

Packaging & Availability

- Packaging Type

- Packing

Coils packed in individual boxes, vacuum packed with desiccant. Product delivered with batch number and traceability. Other formats up to 25kg are available on request.

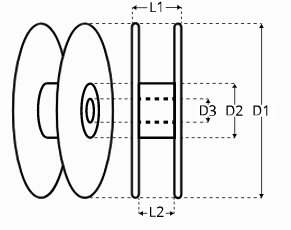

Spool L1 L2 D1 D2 D3 500g 55 45 200 105 52 2kg 100 90 300 210 52

Storage & Handling

- Storage

- It is advisable to store your coils in a dry place, if possible accompanied by desiccant.

- To ensure a perfect impression, it is advisable to steam your filament at 50°C for 4 hours or more when the spool has been exposed to the open air for a long period.