Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

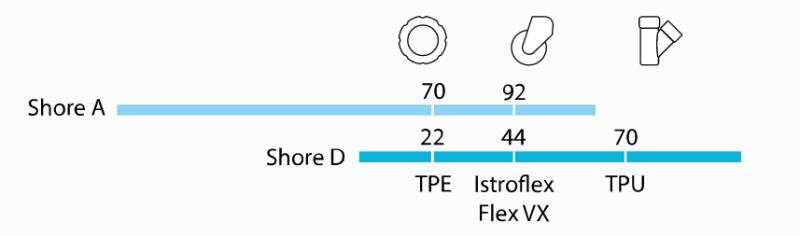

- With a Shore hardness close to a 70D construction helmet, this filament will allow you to create semi-rigid, wear-resistant functional structures while remaining flexible.

- This FDM thermoplastic polyurethane suitable for outdoor use is ideal for creating silent blocks, hard wheels, soles, pipes, shock absorbers, orthopedic prostheses, safety equipment, etc.

- Advantages

- Low temperature flexibility down to -32°C.

- UV resistant.

- Abrasion resistant.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Usage Tips

Impression

With printability parameters close to standards, the Nanovia TPU 70D filament can be used with the majority of 3D printers on the market equipped with a closed enclosure.

- Extrusion temperature: 230°C.

- Chamber temperature: 50°C.

Post treatment

Unlike the more flexible TPU and TPE, it is possible to sand the Nanovia TPU 70D.

Properties

- Color

- Physical Form

- Mechanical Properties

- Typical Properties

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.12 | g/cm3 | ISO 1183 |

| Hardness | 70.0 | Shore D | — |

| Resistance to Traction | 28.0 | MPa | ISO 527 |

| Elongation at Break | 320.0 | % | ISO 527 |

| Traction Stress (100% Elongation) | 20.0 | MPa | — |

| Traction Stress (300% Elongation) | 28.0 | MPa | ISO 527 |

| Value | Units | Test Method / Conditions | |

| Extrusion Temperature (3D Printing) | 225 - 245 | °C | — |

| Plateau Temperature (Ambient, 3D Printing) | -50.0 | °C | — |

| Enclosure Temperature (3D Printing) | 50.0 | °C | — |

| Nozzle (3D Printing) | All | — | — |

| Printing speed (3D Printing) | 20 - 70 | mm/s | — |

| Diameter | 1.75 (+/- 50) | mm(µm) | — |

| Linear Mass (3D Printing, Ø 1.75 mm) | 2.69 | g/m | — |

| Linear Mass (3D Printing, Ø 1.75 mm) | 7.14 | g/m | — |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | -16.0 | °C | — |

Technical Details & Test Data

- Nanovia Hoses

Safety & Health

- Health and Safety

Post treatment

Wearing standard PPE (mask, gloves) is recommended during post-processing of parts printed with the Nanovia TPU 70D.

Packaging & Availability

- Packaging Type

- Packing

Coils packed in individual boxes, vacuum packed with desiccant. Product delivered with batch number and traceability.

Other formats up to 25kg are available on request.

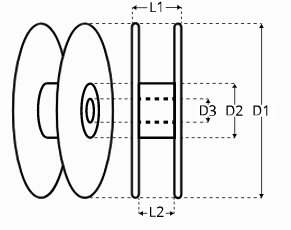

Spool L1 L2 D1 D2 D3 500g 55 45 200 105 52 2kg 100 90 300 210 52

Storage & Handling

- Storage

- It is advisable to store your coils in a dry place, if possible accompanied by desiccant.

- To ensure a perfect impression, it is advisable to steam your filament at 60°C for 4 hours or more, when the spool has been exposed to the open air for a long period.