Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features

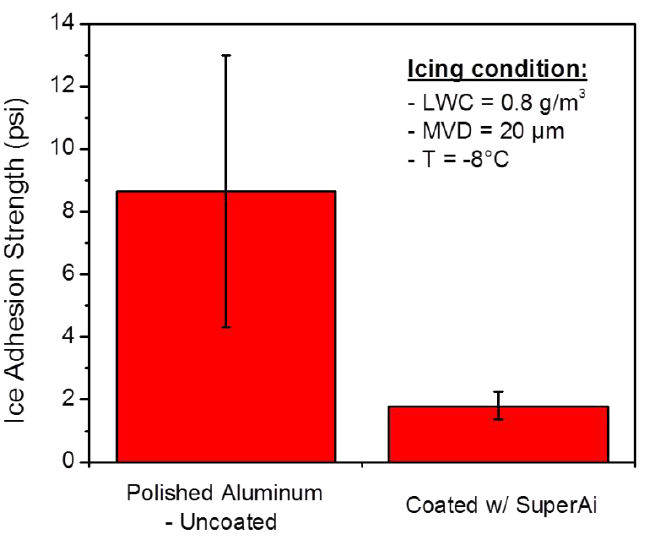

- Decreases ice adhesion by 60 to 80%

- Transparent and glossy finish, with low haze

- Dries thin: < 1 mil

- Low VOC

- Product can be applied to a variety of substrates

- Low viscosity formulation spreads quickly – even over complex surfaces

- Benefits

- Weather Resistant - Hydrophobic surface repels water and reduces ice build up

- Easy-to-Clean - Lower friction, slippery surface makes it resistant to contamination and easier to clean up

- Easy Application - Can be applied by brush, spray, or wipe, with no primer or curing required

- Durability - Increases the service life of coating by preserving protective functions

- Cost Savings - Reduces raw material, labor, and energy cost of repainting or recoating

- Maintenance - Eliminates the need to frequently repaint or replace damaged coatings

Applications & Uses

- Application Method

- Coating Application

It is recommended that coating application be performed in a clean environment to minimize surface defects. The coating can be applied by immersion, spraying, rolling, or brushing. Only one coat is required to cover the substrate. Under ambient conditions (25°C / 77°F, 50% RH), a single coat is 5 – 15 μm (0.2 - 0.6 mil) thick. Dilute with isopropanol as needed.

- Spraying :

When surface preparation is complete and surface is dry and free of dust, begin application using a high volume, low pressure (HVLP) spray gun with a 1.0 size tip and the pressure set at approximately 25 to 30 psi. On a separate piece of cardboard, first spray a test pattern to achieve a 6” to 8” elongated pattern approximately 1½” wide in the middle and fluid enough to cover but not puddle. If there is high wind, this will affect the quality of the finish as blowing wind can disrupt the spray pattern from your HVLP. It can also contribute to contamination of the finish with blowing dust. It may be necessary to erect a windscreen to protect the area. Once the spray pattern is achieved on the test cardboard, spray one coat in a cross-pattern; left to right, then up and down. This will provide sufficient coverage and will help prevent holes in coverage. Desired wet film thickness (WFT) is approximately 2.0 to 2.5 mils (spraying undiluted solution).

If using spray application method in an enclosed space, make certain to tent off the area being sprayed with plastic tarps to avoid spray dust from traveling and contaminating other surfaces with overspray dust. Tented and enclosed areas always require to be positively supplied with fresh air and have ventilated exhaust to outside using fans. Never spray near any open flame or any possible source of ignition such as pilot light, or anything that may spark, as this may cause ignition and explosion of the fumes and vapors.

- Rolling :

Make certain the surface is clean as per preparation instructions. Using a white, ultra-smooth high-density foam roller, pour SuperAi into a roller pan and completely saturate the roller. Apply in a cross-pattern; left to right, then up and down as quickly as possible as the coating dries fast. Avoid down pressure on the roller to achieve a better looking finish.

- Brushing :

Make certain the surface is clean as per preparation instructions. Select the appropriate size brush width based on the surface area being coated. Using only a good quality China bristle brush, apply SuperAi in a cross-pattern; up and down, then left and right. To obtain the best results, do not overwork the coating as it dries fairly quickly. Do not bear down with the brush. Use light strokes using the tip of the brush to smooth out the coating. Desired wet film thickness (WFT) is approximately 2.0 to 2.5 mils.

- Spraying :

- Clean Up

Clean tools and flush equipment immediately after application is completed with acetone thoroughly before product dries. Once coating is dry, the tools will not clean with acetone or any other solvent.

Properties

- Physical Properties

- Technical Data

| Value | Units | Test Method / Conditions | |

| Solids Content | 18 - 20 | % | — |

| Value | Units | Test Method / Conditions | |

| Coverage | 110 (1200) | m² (ft²/gallon) | — |

| Cured Film Thickness | 5 - 15 | μm | — |

| Curing Temperature | 20 - 150 | °C | — |

| Water Contact Angle | 100 - 105 | degree | — |

Technical Details & Test Data

- Surface Preparation

Ensure surfaces to be coated are clean, dry, and in sound condition. Before applying SuperAi, remove all oil, grease, dust, dirt and other foreign material by using an appropriate cleaner. To ensure that the surface is completely free of oil and grease, use a lint-free white cloth with a solvent such as alcohol or acetone, and wipe the surface. If the cloth remains white, the surface is clean; if the cloth turns dark, continue cleaning until it remains white. Once clean, SuperAi can be applied by following the instructions below.

- Curing

- Ambient Curing : Under ambient conditions (25°C / 77°F, 50% RH), a single coat will be dry to the touch in 1 hour and completely cured in 24 hours.

- Accelerated Curing : In order to accelerate curing, let the coated surface dry in ambient air for 10 minutes and then heat to at least 105°C for a minimum of 5 minutes, preferably ~15 minutes. An oven, blow dryer, or heat gun may be used (maximum temperature is 150°C).

- Product Highlights

NANOMYTE® SuperAi is a nanocomposite coating that imparts anti-icing properties to the underlying substrate. The transparent coating also provides a hard, dense, and smooth finish. Surfaces treated with SuperAi exhibit reduced ice adhesion, thereby preventing ice buildup. SuperAi is a versatile coating that can be applied directly on a variety of substrate materials, including plastics, metals, glass, concrete and ceramics. SuperAi cures under ambient conditions.

In independent tests performed at multiple sites, it has been shown that NANOMYTE® SuperAi reduces the adhesion strength of ice by as much as 80%, compared to bare metal and painted surfaces. This in turn leads to reduced ice accretion. The use of SuperAi in applications such as wind turbines, overhead high voltage power lines, transportation, marine, and others enhances productivity and energy efficiency, thereby providing a good return on investment.

The coating can be applied by brushing, spraying or wiping. The dry film thickness can be adjusted to be in the range of 5 – 15 microns (1/5th to 3/5th of a mil). Only one coat is required to cover the substrate. The liquid coating solution is available in liter and gallon quantities.

Left : Aluminum coated with NANOMYTE® SuperAi exhibits about 80% reduction in ice adhesion.

Right : Uncoated surface shows cohesive failure within ice, while one coated with SuperAi had adhesive failure at the interface.

Packaging & Availability

Storage & Handling

- Storage and Handling

Precautions for Safe Handling :

Appropriate personal protective equipment should be used at all times. Provide good ventilation or extraction. Avoid prolonged or repeated breathing of vapor. Avoid contact with eyes, skin and clothing. Keep away from heat, sparks, flames and other sources of ignition. Wash hands thoroughly after handling.

Conditions for Safe Storage (including any incompatibilities) :

Avoid storage over 100° F and contamination with incompatible materials. Keep containers tightly closed in a cool, well ventilated place. Protect from moisture. Residual vapors might explode on ignition. Do not apply heat, cut, drill, and grind or weld on or near this container.