Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Composites Processing Methods

- Processing instructions

The mixture of components is very important, poor mixing may results in soft spots.

Mix thoroughly in a container, transfer the mixture into a clean container and mix further. Dosage should always be made on a scale with sufficient accuracy or a well calibrated dosage system.

NM Infusion 639 has a low reactivity and the viscosity increases very slowly during the infusion process. Large and complex structures can be infused without problems.

NM Infusion 693 is not suitable for open mold processes, due to the low viscosity. For such applications, NM Laminering 625, NM Laminering 650 or NM Laminering 3070 are recommendable.

- Surface Preparation

Film forming release agent is recommended, for example Marbocote 220. Wax‐based release agents are normally not recommended and test should be performed before use of these types.

- Post work

A dry surface must be sanded to ensure adhesion to the next layer.

Properties

- Chemical Resistance

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Cleaning Solvent | Acetone | — | — |

| Resin | NM Infusion 693 | — | — |

| Hardener | NM Härdare 650 B | — | — |

| Mixing Ratio (Weight, Volume) | 100 - 45 (100 - 54) | — | — |

| Density | 1079 | kg/m3 | — |

| Viscosity | 0.8 | mPa·s | — |

| Dry Content | 100 | % | — |

| Pot Life (100g 20°C) | min. 180 | minutes | — |

| Flexural Strength (4H,150°C / 302°F + 1H,180°C / 356°F) | 91.5 | MPa | — |

| E‐Modulus (4H,150°C / 302°F + 1H,180°C / 356°F) | 3 | GPa | — |

Technical Details & Test Data

- Curing

Curing can take place at room temperature or as a post‐curing at elevated temperature.

The low reactivity involves a long demoulding time at room temperature curing. TG should as a minimum reach room temperature before demoulding.

TG development at +23°C/73°F curing temperature can be seen in the table below typical properties.

An increase or decrease of the curing temperature with 10°C gives a halved resp. doubled demoulding time.

NM Infusion 664 should first cure at room‐temperature (20 – 23°C / 68 – 73°F) for 24 ‐ 30 hours before post‐curing.

It is important that the temperature is ramped up slowly to the final curing temperature. Normal increases are between 0.1 ‐ 0.3 K per minute. It is often a combination of thickness and laminate structure, which determines the speed. The optimum cure cycle must be determined for each case.

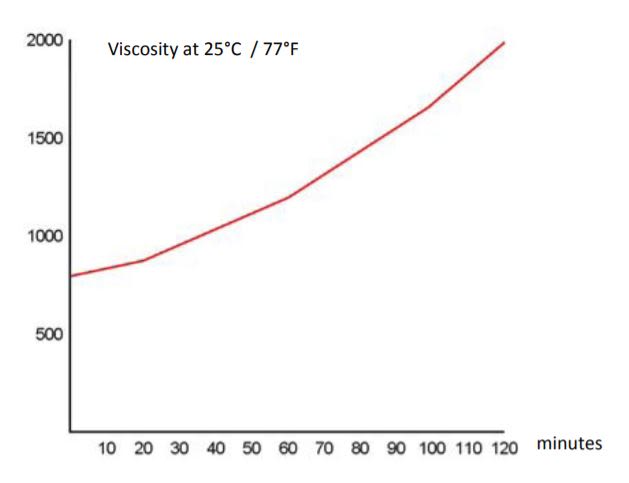

- Viscosity development at 25°C/77°F

Storage & Handling

- Storage

Storage stability of NM Infusion 693 is about 6 months at room temperature. Storage at low temperature is recommended.

NM Infusion 664 can be stored for a longer period at room‐temperature and be post‐cured later.