Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Highlights

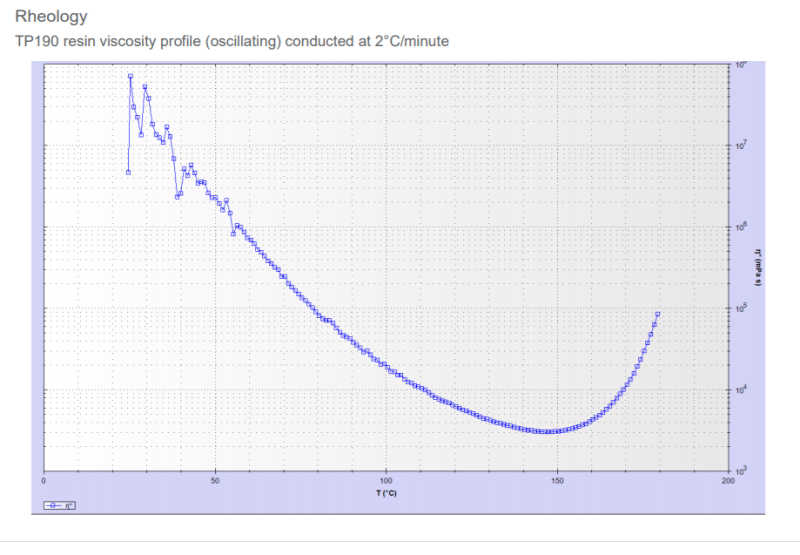

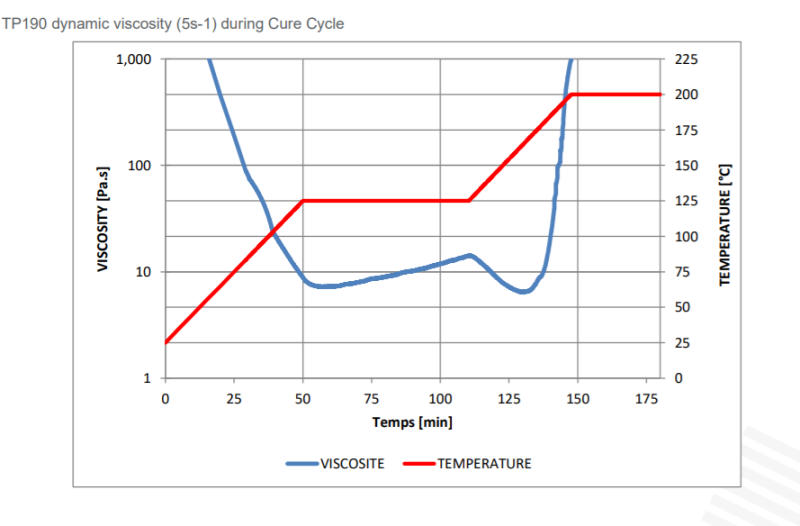

This hot-melt epoxy prepreg is recommended to be cured at 200°C for the best thermal stability properties and a Tg until 210°C Onset (by E’ DMA). This matrix has a very good flow control. TP190 offers excellent mechanical properties on a wide variety of fibers, and fiber weights.

TP190 is commonly used in autoclave processes and press molding. TP190 achieves very high mechanical properties (like ILSS~105MPa and Compression~1533 MPa on T800S fiber) and Tg which make it suitable for structural parts in demanding applications such as aeronautic, motorsport and high-end industry. NTPT prepreg products are often used with automated tape laying machines (ATL). Our products are formatted both for ATL and for manual layup.

- Features

• Very high-Tg prepreg system (210°C Onset) combining very high-strength

• Excellent thermal stability and hot wet performances • Great toughness (damage tolerance)

• Cure 4h at 200°C (or 180°C minimum)

• Suitable tack for most hand layup and automated tape placement processes

• Ideal for prepreg with fiber weights from 60gsm to 150gsm

• Very good flow control

• Autoclave and press curable

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Instruction for use

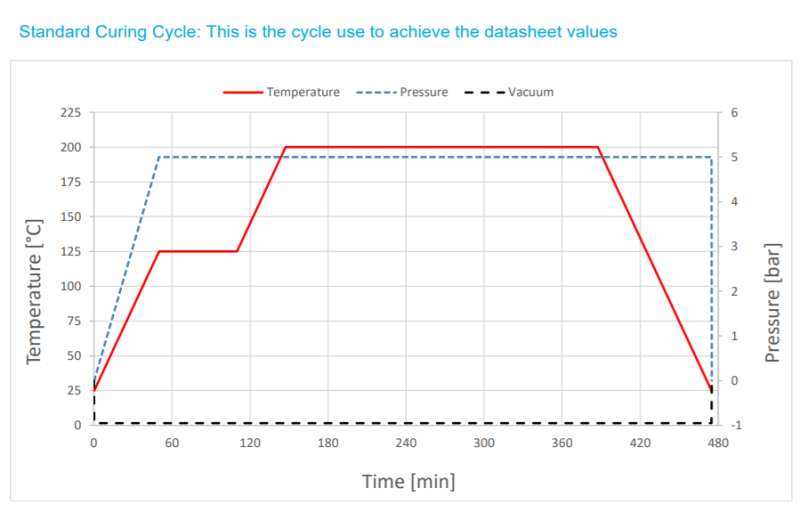

Curing cycles

For the highest thermal properties of the composite, the laminate should be cured at 200°C for a minimum of 4 hours. However, there is a lower curing cycle possible for TP190, by reducing the dwell at 180°C.

Note: NTPT recommends 4 hours at 200°C cure cycle to fully cross link the TP190 matrix resin and develop the best balance properties for the composite. A lower temperature cure cycle is possible, 4hrs at 180°C, with a lower Tg (196°C Onset). NTPT always advises that users should perform tests and satisfy themselves on the suitability of the product and the intended cure cycle through the manufacture of and mechanical testing of tests panels before commencing the production item. Please contact NTPT Technical Services department for further advice on this point.

Attention: TP190 is a highly energetic system with a very high level of cure enthalpy, typically >500J/g. In cases when TP190 is envisaged to be used in thick laminate format i.e. >4mm in thickness, extra care needs to be taken with the curing. We recommend a slow ramp rate, as well as well one or two intermediate dwells so that cross linking energy can be managed. We recommend that precautions are taken so that in the event that an uncontrolled exothermic reaction is created, there should be some user intervention and laminate temperature should be actively managed lower. Management strategies include removing the heat source used for curing e.g. turn off the press or oven, passing cooled air over the part, or in extreme situations submerging the part in a large reservoir of cold water (can be done with the part remaining in the vacuum bag). TP190 users can seek specific advice on this point by contacting NTPT’s Customer Support Team. NTPT advises that in all cases trials and sample parts should be made to confirm the suitability of process parameters to confirm the intended cure cycle will produce the parts as planned. NTPT specifically limits its liabilities to zero from damages caused through the use of NTPT products in the manufacturing processes of our customers.

Material preparation

When preparing the lay-up, the prepreg should be removed from the freezer and allowed to thaw in a sealed bag. This may take 6 to 24 hours depending on roll size. This prevents atmospheric moisture from condensing on the prepreg which may cause voiding on cure. The mold surface should be release coated and must have been tested for vacuum integrity prior to lay-up. Thin laminates: When using very thin laminates (e.g. with a total laminate fiber weight of less than 300gm2 ), care needs to be taken to avoid extracting excessive amounts of resin during the cure process. To avoid this, a microporous release film can be used, and for particularly critical components, a prepreg peel ply should be used.

Laying-up

The following procedure is recommended for preparing vacuum cured laminates.

1. Place the lay-up on a tool or caul sheet which has been treated with a release agent or film. Insert a thermocouple into the lay-up near the center ply of the thickest edge section, outside the net trim line. A separate prepreg nylon peel ply is available for covering a mold tool prior to lay-up in order to leave a clean, textured surface for subsequent bonding.

2. Apply a peel ply to the surface of the lay-up. Note that for good secondary bonding of a peel-plied surface of a TP190 prepreg laminate, a nylon peel ply is strongly recommended. This is particularly important where the cure temperatures are in excess of 90°C. Cover the peel ply entirely with a perforated release film. Normally, no edge resin bleeder system is used.

3. Install a vacuum bag by standard techniques. Insert at least two vacuum stems through the bag connecting one to the vacuum source and the other, at a point on the part furthest from the source, to a calibrated vacuum gage. Position part in the oven or autoclave and draw vacuum to check for bag or system leaks.

4. Follow the recommended cure cycle as above.

5. Upon completion of cure, turn off heat and cool until part temperature has fallen below 60°C. When fully cooled, the part may be debagged, trimmed and machined as necessary. A post-cure is not required.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Flexural Modulus | 4.71 | GPa | ISO 178 |

| Flexural Strain | 5.78 | % | ISO 178 |

| Flexural Strength | 219.5 | MPa | ISO 178 |

| Glass Transition Temperature (Tg by E' DMA) | 206.3 | °C | ISO 6721 |

| Glass Transition Temperature (Tg by tand DMA) | 221.8 | °C | ISO 6721 |

| Resin Density | 1.327 | g/cm3 | ISO 1183-3 |

| Tensile (Modulus) | 4.35 | GPa | ISO 527-2 |

| Tensile (Strength) | 88.7 | MPa | ISO 527-2 |

| Tensile Strain | 3.26 | % | ISO 527-2 |

Technical Details & Test Data

- Product Format

TP190 STANDARD PRODUCT FORMAT USE Hand Lay-up Preform from ATL Backing Paper Silicon paper (50 or 100µm) Silicon paper (75µm) or polyester foil (50µm) Top release None or Polyethylene foil Polyethylene foil or embossed Width [mm] 300 mm up to 1500mm Available FAW [gsm] Range from 60 to 150gsm per 30 gsm step from 2 to 8 layers (16 with thin ply) Mass Resin Content [%] Range from 30% to 55% (thin ply 38% minimum) Cardboard tube [mm] Inner diameter 76mm (3 inches) 300mm Width 320mm 1600mm - Typical Characteristics

Safety & Health

- Health and safety

TP190 contains epoxy resins which can cause allergic reaction. When uncured, TP190 should be handled with appropriate gloves. When cured, a composite laminate made of TP190 should be cut, drilled or machined in a room equipped with an exhaust ventilation and filtration system, by operators wearing protective cloth and masks. Refer to Material Safety Data Sheet for further information.

Storage & Handling

- Storage

When stored sealed & out of direct sunlight.

Storage Temperature Value Unit Shelf Life (-18°C) 12 months Out Life (+18-22°C) 4 weeks Tack Life (+18-22°C) 3 weeks All prepreg materials should be stored in a freezer when not in use to maximize their useable life, since the low temperature reduces the reaction of resin and catalyst to virtually zero. However, even at -18°C, the temperature of most freezers, some reaction will still occur. In most cases after some years, the material will become unworkable.