Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Features

• Wide range of Fiber Areal Weight, including extremely light tapes

• Cyanate ester resin with Tg of 350°C (660°F)

• Low coefficient of Thermal Expansion

• Out life of 30 days at 21°C (70°F)

- Benefits

• Almost unlimited possibilities of composite structure design

• Ideal for high temperature applications

• Very good dimensional stability of composite part in a wide range of temperature of use

• Possibility of making large and/or complex parts with long mold dressing time before curing

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Instruction for Use

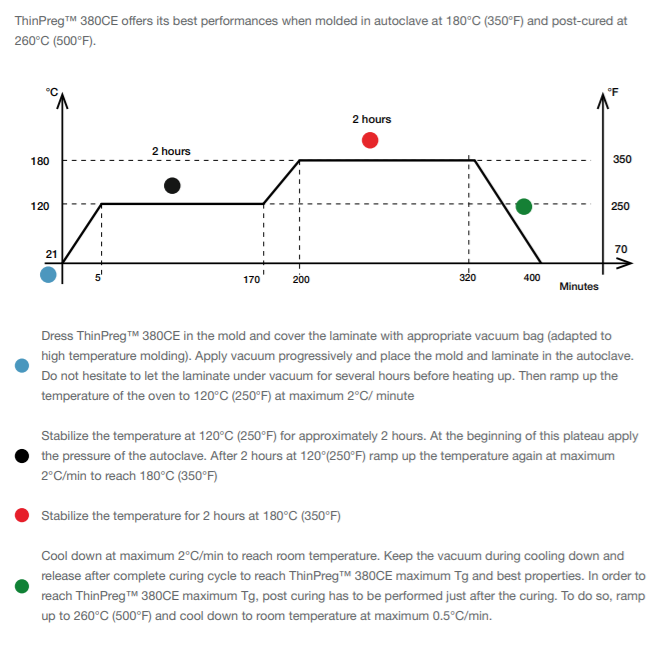

Curing cycle

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.3 | g/cm3 | ISO 1183-3 |

| Elongation at break | 0.71 | % | ISO 527-2 |

| Flexural modulus (mean value) | 4223.2 | MPa | ISO 178 |

| Flexural strength (mean value) | 87.6 | MPa | ISO 178 |

| Fracture toughness G1C | 0.062 | kJ/m2 | ISO 13586 |

| Fracture toughness K1C | 0.443 | MPa.m1/2 | ISO 13586 |

| Heat deflection temperature | 161 | °C | ISO 75-2 |

| Maximum Tg after post-cure | min. 350 | °C | — |

| Strain at maximum load (mean value) | 2.3 | % | ISO 178 |

| Tensile modulus | 4055 | MPa | ISO 527-2 |

| Tensile strength | 2845 | MPa | ISO 527-2 |

| Water absorption (boiling water) | 0.15 | % | ISO 62 |

Technical Details & Test Data

- Product Characteristics

Cured ThinPregTM180 CE/CF properties on a UD laminate (after the above mentioned curing cycle has been applied) With Toray Fiber M55J Test Method International System of Units American System Fiber volume / weight fraction 55 / 66 % Tensile strength 1649 MPa 239 ksi Tensile modulus 315 GPa 45.7 Msi Interlaminar Shear Strength for the laminate structure: 100%@0° 33.9 MPa 4.9 ksi ASTM 2344 - 84

Safety & Health

- Health and safety

ThinPreg™ 380CE contains cyanate ester resins which can cause allergic reaction. When uncured, ThinPreg™ 380CE should be handled with appropriate gloves. When cured, a composite laminate made of ThinPreg™ 380CE should be cut, drilled or machined in a room equipped with an exhaust ventilation and filtration system, by operators wearing protective clothing and masks. Refer to Material Safety Data Sheet for further information.

Packaging & Availability

- Packaging

ThinPreg™ 380CE is wound into 300 mm (11.8 inches) wide rolls on a 76 mm (3 inches) or 150mm (6 inches) inner diameter cardboard tube. ThinPreg™ 380CE is supported on a bottom silicon paper. The standard roll length is 150 linear meters (164 yards).

Storage & Handling

- Storage

ThinPreg™ 380CE should be stored at -18°C (0°F) to reach the maximum shelf life of 24 months. At 21°C (70°F), the out life is 30 days.